Review Article - Journal of Food Science and Nutrition (2018) Volume 1, Issue 1

Conventional industrial ice cream freezers and its thermal design: a review.

Awani Shrivastav, TK Goswami*Department of Agricultural and Food Engineering, Indian Institute of Technology, Kharagpur, India

- *Corresponding Author:

- TK Goswami

Department of Agricultural and Food Engineering

Indian Institute of Technology

Kharagpur,

India

Tel: +91-322-227-7362

E-mail: tkg@agfe.iitkgp.ernet.in

Accepted date: January 20, 2018

Citation: Shrivastav A, TK Goswami. Conventional industrial ice cream freezers and its thermal design: a review. J Food Sci Nutr. 2018;1(1):21-28.

DOI: 10.35841/food-science.1.1.21-28

Visit for more related articles at Journal of Food Science and NutritionAbstract

Freezing is the most important process in any ice cream manufacturing plant. The quality of the end product mainly depends upon the various parameters chosen during freezing process. So far many batch and continuous freezers has been developed and various modifications are made in them in order to achieve more acceptable quality of frozen product. Scraped surface freezers (SSFs) are mainly used for viscous and sticky products. In scraped surface freezers, product come in direct contact with the freezing wall and scraper blades continuously scrapes off the mixture near the wall and mixes it back with product. This action leads to high heat transfer coefficient. Due to the versatility of SSFs in various operations, they are most commonly used. Also design parameters should be properly selected based on the existing models that give least errors. In this review article, various types of ice cream freezers and thermal design involved in SSHE/SSFs are explicitly discussed.

Nomenclature

| A | scraped surface area (m2) |

| U | overall heat transfer coefficient (W/m2.K) |

| ΔTlm | Log mean temperature difference (K) |

| Q | Heat transfer rate |

| m | mass flow rate (kg/s) |

| j | fluid specific enthalpy (J/kg) |

| h | heat transfer coefficient (W m-2K-1) |

| Rw | wall thermal resistance (K/W) |

| D | exchanger tube diameter (m) |

| k | thermal conductivity (W m-1 K-1) |

| L | Length of the tube (m) |

| ρ | density (kg m-3) |

| v | fluid velocity (m s-1) |

| µ | dynamic viscosity (Pa s) |

| N | rotational velocity (r.p.s) |

| nb | Number of blades |

| Nu | Nusselt number |

| Bo | Boiling number |

| Fc | Correction factor |

|

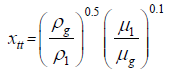

Martinelli parameter |

| x | vapour quality |

| Re | Reynolds number |

| Pr | Prandtl number |

| Po | Power number |

| We | Weber number |

| BF | Blade factor |

Subscripts

| i | Inner-side |

| o | Outer side |

| in | Inlet-section |

| out | Outlet-section |

| s | shaft |

| t | tube |

| l | liquid |

| g | gas |

Keywords

Ice cream, Heat transfer Coefficient, Batch, Continuous, SSFs

Introduction

Ice cream is a frozen dessert of great nutritional value and is consumed by people of different age groups. Milk solid-notfat (MSNF), milk fat, various sweeteners, stabilizers and emulsifiers, flavorings, and water are the basic ingredients of ice cream mix [1].The manufacturing process of ice cream mainly consists of two stages: Mix manufacturing and freezing. However, based on scale of manufacturing, the process varies from factory to factory [2]. Mix manufacturing includes the series of unit operations like blending of ingredients, batch and/or continuous pasteurization, homogenization, cooling and finally aging [3,4]. After the mix manufacturing operations, ice cream formation will involve two stages: Freezing and Hardening [5].

Freezing of ice cream in an initial process is called dynamic freezing where the ice cream mixture is simultaneously agitated with the incorporation of air. This is the most important step of an ice cream manufacturing process, as the ice crystals formation takes place at this stage only [6]. During this process, dispersion of air bubbles and rearrangement of fat globules take place [7]. Initial freezing or dynamic freezing process is carried out in scraped surface heat exchanger or freezer [5]. After this, Static freezing or hardening is done where a very low temperature environment is maintained [8]. In the hardening process, ice cream is usually hardened to -18°C or ideally to -25 to -30°C [9].

Ice cream comes under the category of highly viscous product and tends to stick on the surface when using conventional plate or tubular heat exchangers. So far many freezers have been developed for manufacturing of ice cream but scraped surface heat exchanger (SSHE) is most commonly used in the food industries. According to Rao and Hartel [10], heat transfer in case of viscous and sticky products is only possible by using SSHE. Due to its versatility, SSHEs have been used for many years in various food industries for the processing of highly viscous products [11].

Initially, Harrod and Abichandani et al. has made a review on SSHEs [12,13]. After that Rao and Hartel [10] have presented a very good review on all the work that has been done on SSHEs. These reviews cover the variety of topics like flow pattern [14], overall hydrodynamics [15], residence time distribution (RTD) [16,17]. The readers can also refer to the various papers published describing heat transfer phenomenon in SSHEs [18-21]. This review covers the design aspects of SSHE, advancement made in SSHE and the other types of freezers available for ice cream freezing.

Historical Perspective of Ice-cream Freezer

The ice cream industry was mainly started in 1905 and they started using vertical tube freezer with ice and salt brine as refrigerant. After this, many experiments were conducted by Mr. Valerius of the Creamery Package Manufacturing Co. from 1907 to 1909, for the improvement of continuous freezer. In 1915, many industries began to use the horizontal brine-type freezer on a large scale. By 1920, the era of manufacturing Icecream with horizontal brine type freezers in the industries of large cities began. The freezers of 40 to 100 qt. capacity were mostly used for the larger production of ice cream [22].

Another improvement in the freezer was made by Miller. He developed a batch-type of ice cream freezer in which brine of low temperature was used as a refrigerant and the working assembly consists of a dasher with a scraper blades and beater. After this, several equipment makers of America and Europe started manufacturing batch freezers [23].

In 1926, Clarence Vogt developed another improved and successful continuous ice cream freezer. In this freezer, product was aerated and made to flow under pressure in a closed cylinder. After this, many more such kind of continuous ice cream freezers were developed [23]. In 1927, Creamery Package Manufacturing Co. along with York Co. developed direct expansion type batch freezers in which instead of brine, ammonia was used as a refrigerant. By 1935, with the introduction of the Creamery Package continuous ice cream freezer and Vogt freezer, most of the industries started using continuous type freezers [22]. A modern continuous freezer has the rate of ice cream production of about 3000-4000 (l h-1) [24].

After this many inventions were made to do the improvement in ice-cream freezer. In 1951, Jacob Fussell became the father of ice cream industry, establishing the first large scale commercial Ice-cream plant. Fussell sold his business to Borden at a later stage.

Later on the development in the conventional continuous freezer was made. Product temperature coming out of the conventional freezer was -5˚C. Temperature was further reduced to -15˚C with the combination of conventional continuous freezer and Low Temperature Extrusion (LTE) Freezer [25,26].

Freezers for Ice Cream

Thermal treatment of viscous products like ice cream results in fouling and scale formation. Fouling and scale formation in heat exchangers is undesirable from the heat transfer point of view. As the thickness of deposited film increases, flow will become laminar and reduces the heat transfer rate. Also this will result in rise in pressure to pump the product through the heat exchanger and hence will increase the power requirement [27].

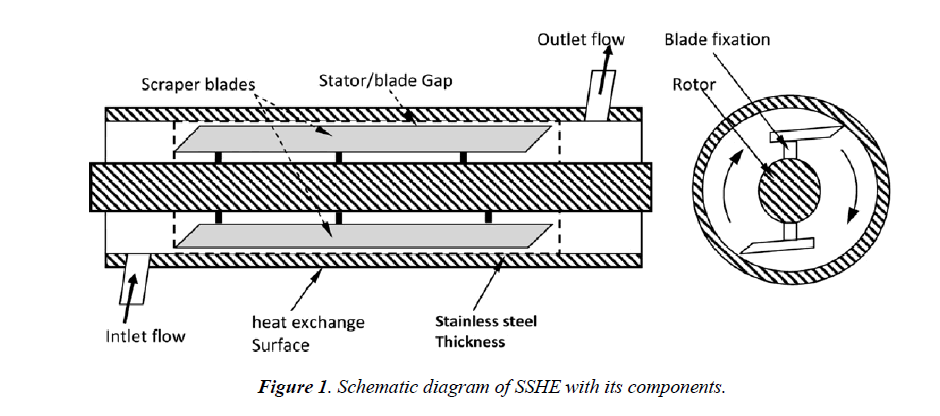

The selection of heat exchanger depends upon the type of product need to be processed. To reduce the resistance due to film formation, the liquid film must be as thin as possible and there should be continuous film renewal, which is not possible in case of conventional tubular and plate heat exchangers. Scraped surface heat exchanger (SSHE) or freezer (SSF) consists of scraper blades and beater assembly. Scraper blades continuously scrapes the frozen film from the cylinder wall, mixes it back to the mixture and carry it from one end of the freezer to the other end for the uniform cooling unloading [28,29]. The first SSHE was used for freezing of ice cream and then after that, it was used for chilling, plasticizing and crystallizing of butter and margarine [30]. A Schematic diagram of SSHE with its components (Figure 1) [31].

Classification of Scraped Surface Ice cream Freezer

Based on the mode of operation SSFs are classified as batch and continuous type. Batch freezers are those in which predetermined amount of ice cream mix is frozen batch-wise while continuous freezer consists of continuously feeding the ice cream mixture at one end of the freezer and taking out the ice cream from the other end [1,7,8].As the mixture passes through barrel, the rotor inside the barrel mixes the ice cream mix with the air and after that ice cream mixture being aerated and partially frozen taken out from the other end of the freezer [32,33].

The application of batch freezers is mostly seen in small ice cream manufacturing plants. For the same capacity, installation cost of batch freezer is much lower compared to continuous freezer [1,8]. The capacity of batch freezers may vary from 6 quarts to 120 quarts. However, for the capacity greater than 40 quarts, continuous type ice cream freezer is preferred [34].

The method of operation of continuous type of SSFs is almost same as the batch type of SSFs but still there are several notable differences. Heat transfer in batch freezer is not as efficient as continuous freezer. Another notable difference is that residence time distribution (RTD) in batch freezer is long as compared to continuous freezer. It takes about 15 to 30 min to freeze the same amount of mixture to desired consistency in batch freezer while approximately 1 to 2 min in continuous freezer. Therefore, ice crystal size is also larger in case of batch freezer as compared to that of continuous freezer. Another significant difference is that ice cream mixture is whipped at atmospheric pressure in batch freezer while air distribution occurs under pressure in case of continuous freezer. Also the whipping properties are less important in continuous freezer as compared to that in batch freezer [35].

Advances in SSHEs

Since the year it was initially developed, many small changes were made in the SSHE, but major modifications were made in the form of Low temperature extrusion (LTE) freezing and product recirculation. These two advancements found to improve the quality of ice cream.

Low temperature extrusion freezing

This is a novel technology in which conventional scraped surface freezer (SSF) is combined with low-temperature extrusion (LTE) freezer. In this frozen product is simultaneously shear treated and frozen to low temperatures of about –10°C to –20°C [36,37]. The ice cream mix coming out of conventional scraped surface freezer (at -5 to -6°C), instead of sending it to the hardening tunnel goes through the LTE freezer [25,38].The mix coming out of freezer is at -5 to -6°C and at this condition about 40-50% of water is frozen. If such mixture is further deep frozen (at about -20°C) in hardening tunnel, the water will crystallize on the surface of existing crystal and would result in increased size. This will reduce the quality as well as shelf life of the product. So the product is subjected to shear stress and goes to low temperature extruder. At this condition, additional crystal nuclei are formed by secondary nucleation and de-aggregation of ice crystal aggregates. Therefore we get 2-3 times more finely dispersed ice crystals than the conventional process [39]. Eisner et al. [40] had found that the maximum air cell diameter is reduced from 52 to 19 μm using a twin screw low temperature extruder.

The extruder can be a single-screw or a twin-screw configuration. The single screw churns the ice cream around the screw and twin-screw kneads and churns the ice cream between 2 parallel screws. The rotational speed of both type of configuration is about 15 rpm [41]. According to Windhab and Wildmoser [39], twin screw extruder results in the reduction of air cell size and ice crystal size by 2-3 folds as compared to conventional freezing and hardening. As per Wildmoser [42], single screw extruder has a very little effect on ice crystal size as compared to twin-screw extruder but air cell size in both the cases is almost similar. Eisner [43] investigated different parameters along the 3 sections of LTE and studied the effect of different process parameters on LTE process.

In the former studies, it was found that ice crystals size is greatly reduced when the LTE process combines with conventional freezing process [44,45]. Chang and Hartel [46] show that ice cream viscosity depends upon the size of air bubbles. As the temperature decreases, viscosity of the ice cream increases and air cell size decreases simultaneously. Bolliger et al. [47] in his study showed that LTE generally enhanced fat destabilization but also resulted in reduction of the size of fat agglomerates.

Product recirculation

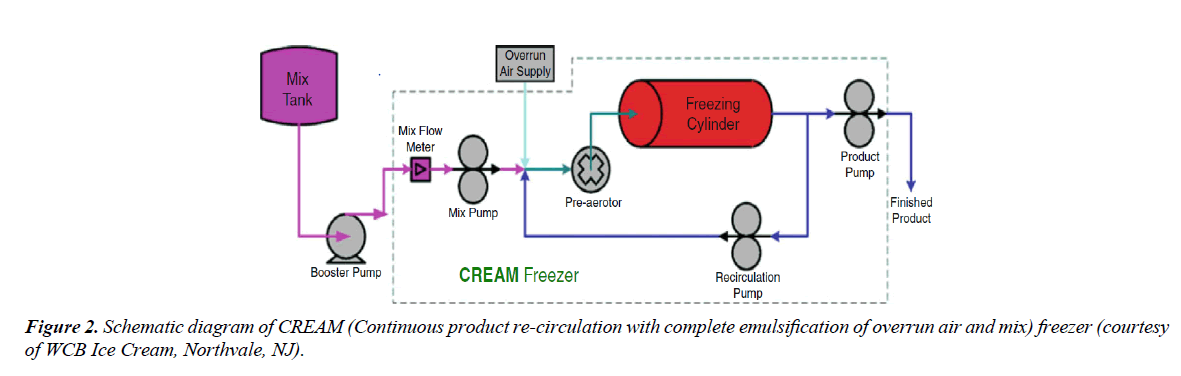

Another modification made in the commercial freezer is by re-circulating some amount of frozen ice cream mix back to the pre-aeration device (Figure 2). Schematic diagram of CREAM (Continuous product Re-circulation with complete Emulsification of overrun Air and Mix) freezer (courtesy of WCB Ice Cream, Northvale, NJ).The re-circulated products results in the cooling of mixture entering the freezer. This will result in enhancing ice crystal formation and reduction of air cell size [7]. The main advantage of using this system is that there will be less chance that the product is left unused and unfrozen. The re-circulating mixture will mix with the fresh mixture and will serve as the site for the growth of ice crystals [48]. This also results in larger residence time distribution and therefore larger ice crystals size distribution [48-51]. Due to increase in residence time, whipping will be more and therefore will break the air cells into smaller bubbles [52-54].

Other Freezer Types

The use of Conventional freezers producing ice cream was a trend from many years. Now there are various other methods exists to produce frozen desserts. The present invention includes cryogenically manufacturing ice cream using liquid nitrogen.

Cryogenic freezing with liquid nitrogen

The basic objective of producing ice cream cryogenically is to make the system less complex and avoid the use of expensive and complicated equipment such as compressors, evaporators, motors, condensers, and other. The other general purpose of this invention is achieve freezing of ice cream more quickly and to save electricity. Jones [55] has patented the invention of method and apparatus for cryogenically manufacturing ice cream. In this invention, air from the supply also includes Liquid Nitrogen (LN2). LN2 is most commonly used in case of food processing as it is liquid at room temperature and can be directly used for freezing (freezing of small drops or pellets in case of ice cream). It has normal boiling point of -196°C at room temperature and when the product is immersed in LN2, dendritic ice crystals are formed [56]. Ice cream mix temperature when drop below -35°C, turns into a glassy state [57,58] and therefore there will be no ice crystallization at this stage. As temperature goes little higher than glass transition temperature, melting and agglomeration will start occurring. Therefore, ice cream should be below this temperature.

Thermal Design of Scraped Surface Ice Cream Freezer

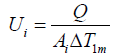

The design of SSHEs is mainly concerned with determining the overall heat transfer coefficient for the particular product and process. The overall heat transfer coefficient for various products has been determined by Bolanowski and Lineberry [30] using votator-type SSHE. Various models have been developed to determine heat transfer coefficient also. All the models developed till the year 1990 has been reviewed by Lee and Singh [17] The overall heat transfer coefficient ‘U’ is calculated based on the inside scraped surface area of the heat exchanger using eq. (1) [59,60].

(1)

(1)

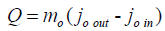

Where, Ai is inside surface heat transfer area, ΔTlm is the logarithmic mean temperature difference and Q is the heat flow rate. Now the heat flow rate Q is calculated by the enthalpy balance either on the coolant side or on the product side, but care must be taken in the measurement of bulk temperature in case of balancing on the product side [59,61]. The enthalpy balance equation on the coolant side is given by eq. (2)

(2)

(2)

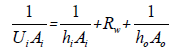

Where, mo is mass flow rate of the refrigerant, and jo,out and jo,in are the enthalpy of outer side fluid or coolant side at the inlet and outlet sections respectively. The overall heat transfer coefficient determination is related to product side and coolant side heat transfer coefficient and follows the most commonly accepted equation as given by eq. (3).

(3)

(3)

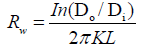

Where, hi and ho are the convective heat transfer coefficients of the product flowing inside of the heat transfer tube and refrigerant or coolant flowing outside of the heat transfer tube, respectively. Similarly, Ai and Ao are the inside and outside surface heat transfer area. Rw is the thermal resistance of the wall and is given as eq. (4)

(4)

(4)

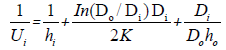

Where, k is the thermal conductivity of the wall and L is the length of the heat exchanger. The eq. (3) can be further simplified by equating the value of Rw in eq. (4) [62].

(5)

(5)

Where, Do and Di are the outer and inner tube diameters. Now to evaluate the overall heat transfer coefficient it is essential to determine convective heat transfer coefficient on the product side and refrigerant side.

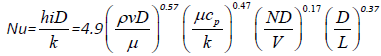

Estimation of convective heat transfer coefficient on the product side

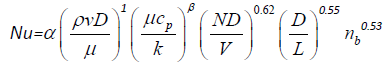

Initially Huggins [63] in his study shows that scraper blades play an important role in improving the heat transfer coefficient for viscous product in case of SSHEs. After this, various empirical models were developed in order to find out the convective heat transfer coefficient on the product side as well as refrigerant side. The various empirical models developed have been reviewed by Lee and Singh [17]. But the most effective model was developed by Skelland [60] that is widely accepted. Skelland [60] has done the work on votator to develop the correlation between dimensionless numbers in order to find out the scraped film heat transfer coefficient.

(6)

(6)

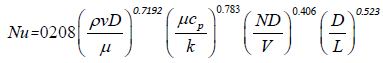

From the eq. (6), scraped side heat transfer coefficient hi can be calculated by knowing the various thermal and rheological properties of the product (in this case ice cream). Later on Skelland et al. [64] has found out that scraped surface heat transfer coefficient is significantly affected by Reynolds number, Prandtl number, shaft speed, shaft diameter and number of blades [17,65]. Therefore, they proposed the following correlation:

(7)

(7)

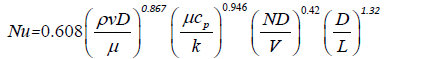

For the cooling of viscous liquids, α becomes 0.014 and β becomes 0.96; while for cooling thin mobile liquids α becomes 0.039 β becomes 0.70 [66]. Boccardi et al. [62] has recently developed two correlations for production of ice cream by adopting the same dimensional analysis technique as proposed by Skelland in developing two correlations. In the first correlation they modified the equation considering the heat exchanger geometry and proposed the following equation:

(8)

(8)

In the second correlation, they introduced cylinder length involved in heat exchange process (Lu), length of the blade (Lb) and number of blades (nb) and developed the new correlations as given in eq. (9)

(9)

(9)

From the above developed correlations, scraped side heat transfer coefficient can be calculated, when all the thermal and rheological properties required in the correlation is known.

Estimation of convective heat transfer coefficient on the coolant or refrigerant side

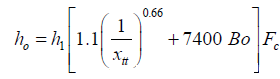

One of the simplest methods to determine the external side heat transfer coefficient is the Wilson plot method [67]. Rose [68] and Fernández-Seara et al. [69] has presented a review on Wilson plot method and made modification in it to determine the convective heat transfer coefficient of various heat exchanger device. The external side heat transfer coefficient can also be calculated using the Schrock–Grossman’s correlation [70], which was later on modified by Nariai et al. [71] for estimation of boiling heat transfer coefficient in a helical coil tube. This correlation was further modified by Kattan et al. [72] by introducing a correction factor Fc for the non-azeotropic behaviour of a refrigerant mixture (R404a) which is given as,

(10)

(10)

Where, χtt is the Martinelli parameter and is given as:

(11)

(11)

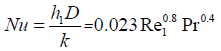

Where, hl is the liquid heat transfer coefficient and can be determine from the Dittus–Boelter correlation [73] which is given as:

(12)

(12)

After the inside (product side) and outside (refrigerant side) heat transfer coefficients are known, length and diameter of heat transfer tube can be calculated.

Power consumption in a SSHE

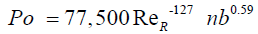

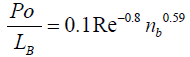

Skelland and Leung [74] have found out the power consumption during cooling of glycerol/water mixture under various operating conditions [75]. Skelland and Leung [74] and Leung [76] have found out that Power number is a function of rotational Reynolds number and number of blades. Therefore, Skelland and Leung [74] developed the correlation as:

(13)

(13)

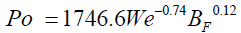

Trommelen [77] has also observed that in the above mentioned correlation, effect of annulus width and length of the blades should also be considered. Abhichandani and Sarma [11] have showed in his study that Power number is a function of Weber number and Blade factor. They developed the correlation using water as a processing liquid. They used water as a processing liquid because water has highest surface tension and hence the Weber number would be the highest. The correlation developed was:

(14)

(14)

Qin et al. [78] has shown in his study that as the ice crystal growth occurs, torque for driving shaft increases. In other words when the phase change occurs, power consumption increases. Therefore, they modeled the power consumption when the phase change occurs and by trial and error method has made some modification in the existing correlations as:

(15)

(15)

Conclusion

Food industry for manufacturing of ice cream comprises of many stages, but freezing is most important step in case of ice cream manufacturing. Various batch and continuous freezers have been developed but continuous type SSFs is most commonly used in the industry. SSFs are widely used because of its various advantages. Proper design and selection of rotor speed and number of blades has to be done. The proper design features is needed to be incorporated for efficient working of SSFs and to improve the final product quality. Further research is needed to be done in order to improve the product quality.

References

- Arbuckle WS. Ice cream. Canada: AbeBooks. 1986.

- Clarke C. The Science of Ice Cream, London, UK: Royal Institute of Chemistry. 2005.

- Goff H. Colloidal aspects of ice cream- A review. Int Dairy J. 1997;7(6-7):363-373.

- Goff HD. Ice cream and frozen desserts. In: Encyclopaedia of Dairy Sciences. San Diego: Academic Press. 2011.

- Russell A, Cheney P, Wantling S. Influence of freezing conditions on ice crystallisation in ice cream. J Food Eng. 1999;39(2):179-191.

- Cook KLK, Hartel RW. Mechanisms of ice crystallization in ice cream production. Comp Rev Food Sci Food Safety. 2010;9(2):213-222.

- Goff HD, Hartel RW. Ice cream. New York: Springer. 2013.

- Marshall RT, Goff HD, Hartel RW. Ice cream. New York: Kluwer Acad. / Plenum Publ. 2003.

- Drewett EM, Hartel RW. Ice crystallization in a scraped surface freezer. J Food Eng. 2007;78(3):1060-1066.

- Rao CS, Hartel RW. Scraped surface heat exchangers. Crit Rev Food Sci Nutr. 2006;46(3):207-219.

- Abichandani H, Sarma SC. Heat transfer and power requirements in horizontal thin film scraped surface heat exchangers. Chem Eng Sci. 1988;43:871-881.

- Abichandani H, Sarma SC, Heldman DR. Hydrodynamics and heat transfer in thin film scraped surface heat exchangers - A Review. J Food Process Eng. 1986;9(2):143-172.

- Härröd M. Scraped surface heat exchangers: A literature survey of flow patterns, mixing effects, residence time distribution, heat transfer, and power requirements. J Food Process Eng. 1986;9(1):1-62.

- Corbett AM, Phillips RJ, Kauten RJ, et al. Magnetic resonance imaging of concentration and velocity profiles of pure fluids and solid suspensions in rotating geometries. Journal of Rheology. 1995;39(5):907-924.

- Baccar M, Abid MS. Numerical simulation of hydrodynamic and thermal behaviors in a scraped surface heat exchanger operating in turbulent regime. International Journal of Thermal Sciences. 1999;634-644.

- Albdelrahim KA, Ramaswamy HS, Grabowski S, et al. Dimensionless correlations for the fastest particle flow in a pilot scale aseptic processing system. LWT - Food Science and Technology. 1995;28(1):43-49.

- Lee JH, Singh RK. Mathematical models of scraped-surface heat exchangers in relation to food sterilization. Chemical Engineering Communications. 1990;87(1): 21-51.

- Dodeja AK, Abichandani H, Sarma SC. Heat transfer during cooling in horizontal thin film scraped surface heat exchanger. Chemical Engineering World. 1990;25(10):49-52.

- Goede RD, Jong ED. Heat transfer properties of a scraped-surface heat exchanger in the turbulent flow regime. Chem Eng Sci. 1993;48(8):1393-1404.

- Mehta PS, Donoian GS. Heat-transfer characteristics of a rotary disk processor. Ind Eng Chem Res. 1990;29(5):829-841.

- Miyashita H, Yoshida M, Nishimura T. Heat transfer correlation in high Prandtl number fluid in Votator type scraped surface heat exchanger. 6th Conference Asia Pacic Confederation of Chemical Engineers. 1993;65-69.

- Farrall AW. Fifty years of progress in dairy plant engineering. J Dairy Sci. 1956;39(6):854-863.

- Mitten HL, Neirinckx JM. Developments in Frozen-Products Manufacture. In: Robinson RK (ed.). Modern Dairy Technology, New York: Elsevier Applied Science Publishers. 1993;281-326.

- Goff HD. 65 years of ice cream science. Int Dairy J. 2008;18(7):754-758.

- Wildmoser H, Windhab EJ. Impact of flow geometry and processing parameters in ultra low temperature ice-cream extrusion (ULTICE) on ice cream microstructure. European Dairy Magazine. 2001;13:26-32.

- Wildmoser H, Scheiwiller J, Windhab EJ. Impact of disperse microstructure on rheology and quality aspects of ice cream. LWT-Food Science and Technology. 2004;37:881-891.

- Lalande M, Rene F. Fouling by milk and dairy product and cleaning of heat exchange surfaces. Fouling Science and Technology. 1988;557-573.

- De S. Outlines of dairy technology. Delhi: Oxford University Press. 1980.

- Farrall AW. Dairy engineering. New York: John Willey and Sons. 1942.

- Bolanowski JP, Lineberry DD. Special heat transfer problems of the food industry. Industrial and Engineering Chemistry. 1952;44(3):657-660.

- Yataghene M, Legrand J. A 3D-CFD model thermal analysis within a scraped surface heat exchanger. Computers & Fluids. 2013;71:380-399

- Darlington R. Heat transfer and heat exchangers in the food industry. Food Manufacture. 1972;47:33-34.

- Smith RW. Applications of plate and scraped surface heat exchangers [in food manufacturing operations]. Food Manufacture. 1972;47:37–38.

- Fouts EL, Freeman TR. Dairy Manufacturing Process. New York: Wiley. 1948.

- Goff HD, Hartel RW. Ice cream and frozen desserts. In: Hui YH (ed.). Handbook of Food Science, Technology and Engineering. Boca Raton. FL: CRC / Taylor and Francis. 2006;4:154-248.

- Hoffmann R, Windhab EJ, Hoyer C, et al. Apparatus and process for cooling foam products. U.S. Patent No. US6082120 A. Washington, DC: U.S. Patent and Trademark Office. 2000.

- Windhab EJ, Fels U, Hoffmann R, et al. Device for cooling fluid and edible membranes. European Patent ep 0 561 118. 1997.

- Windhab EJ, Bolliger S. Low temperature ice-cream extrusion technology and related ice cream properties. Eur Dairy Mag. 1998;24-28

- Windhab EJ, Wildmoser H. Extrusion: a novel technology for the manufacture of ice cream. Bull Int Dairy Fed. 2002.

- Eisner MD, Wildmoser H, Windhab EJ. Air cell microstructuring in a high viscous ice cream matrix. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 2005;263(1-3):390-399.

- Kunzig R. Less fat, better taste. Discover. 2004;25(6):26-7.

- Wildmoser J. Impact of low-temperature extrusion processing on disperse microstructure in ice cream systems. Zurich, Switzerland: Swiss Federal Inst. of Technology, Zurich. 2004.

- Eisner MD. Fat structure development in low temperature extruded ice cream (Master's thesis, Zürich). Laboratory of Food Process Engineering, Swiss Federal Institute of Technology (ETH). 2006.

- Bolliger S. Freezing structuring in food systems under mechanical energy input (thesis). ETH Zurich. 1996.

- Windhab EJ, Wildmoser H, Bolliger S. Production encontinu de cr"eme glace´ e. Revue Ge´ne´rale du Froid. 2001;1011:49-54

- Chang Y, Hartel RW. Development of air cells in a batch ice cream freezer. J Food Eng. 2002;55:71-78.

- Bolliger S, Kornbrust B, Goff HD, et al. Influence of emulsifiers on ice cream produced by conventional freezing and low-temperature extrusion processing. Int Dairy J. 2000;10(7):497-504.

- Hartel RW. Ice crystallization during the manufacture of ice cream. Trends Food Sci Technol. 1996;7(10):315-321.

- Kusumaatmaja W. Effects of mix pre-aeration and product recirculation on ice cream microstructure and sensory qualities (MSc thesis). Madison, WI: University of Wisconsin - Madison. 2009.

- Levenspiel O. Chemical reaction engineering. N.J: Wiley. 1998.

- Schwartzberg HG. Food freeze concentration. In: Schwartzberg HG, Rao MA (eds.). Biotechnology and food process engineering. IFT basic symposium series. New York: Marcel Dekker. 1990;127-201.

- Chang Y, Hartel RW. Stability of air cells in ice cream during hardening and storage. J Food Eng. 2002;55(1):59-70.

- Goff HD. Formation and stabilisation of structure in ice-cream and related products. Curr. Opin. Colloid Interface Sci. 2002;7:432-437.

- Thakur RK, Vial C, Djelveh G. Combined effects of process parameters and composition on foaming of dairy emulsions at low temperature in an agitated column. J Food Eng. 2005;68(3):335-347.

- Jones C. Method and apparatus for cryogenically manufacturing ice cream. US Patent 10,950,053. 2005.

- Hindmarsh JP, Russell AB, Chen XD. Fundamentals of the spray freezing of foods- Microstructure of frozen droplets. J Food Eng. 2007;78:136-50.

- Goff HD, Caldwell KB, Stanley DW, et al. The influence of polysaccharides on the glass transition in frozen sucrose solutions and ice cream. J Dairy Sci. 1993;76:1268-1277.

- Goff HD, Sahagian ME. Glass transitions in aqueous carbohydrate solutions and their relevance to frozen food stability. Thermochimica Acta. 1996; 281:449-464.

- Rainieri S, Bozzoli F, Cattani L, et al. Parameter estimation applied to the heat transfer characterisation of Scraped Surface Heat Exchangers for food applications. J Food Eng. 2014;125:147-156.

- Skelland A. Correlation of scraped-film heat transfer in the votator. Chemical Engineering Science. 1958;7(3):166-175.

- Bozzoli F, Rainieri S, Mordacci M, et al. Experimental Investigation on the Heat Transfer Performance of a Scraped Surface Heat Exchanger for Highly Viscous Foods. 2010 14th International Heat Transfer Conference. 2010;4:713-718.

- Boccardi G, Celata G, Lazzarini R, et al. Development of a heat transfer correlation for a Scraped-Surface Heat Exchanger. Appl Therm Eng. 2010;30(10):1101-1106.

- Huggins FE. Effect of scrapers on heating, cooling, and mixing. Industrial & Engineering Chemistry. 1931;23(7):749-753.

- Skelland AH, Oliver DR, Tooke S. Heat transfer in a water-cooled scraped-surface heat exchanger. Brit Chem Eng. 1962;7:346-353.

- Park KJ. Scraped-surface heat exchange. 1969.

- Boxtel LB, Goethart RL. Heat transfer to water and some highly viscous food systems in a water-cooled scraped surface heat exchanger. J Food Process Eng. 1983;7(1):17-35.

- Wilson EE. A basis of rational design of heat transfer apparatus. ASME Journal of Heat Transfer. 1915;37:47-70.

- Rose JW. Heat-transfer coefficients, Wilson plots and accuracy of thermal measurements. Experimental Thermal and Fluid Science. 2004;28(2-3):77-86.

- Fernández-Seara J, Uhía FJ, Sieres J, et al. A general review of the Wilson plot method and its modifications to determine convection coefficients in heat exchange devices. Appl Therm Eng. 2007;27:2745-2757.

- Schrock VE, Grossman LM. Forced convection boiling in tubes. Nuclear Science and Engineering 1962;12(4):474-481.

- Nariai H, Kobayashi M, Matsuoka T. Friction pressure drop and heat transfer coefficient of two-phase flow in helically coiled tube once-through steam generator for integrated type marine water reactor. Journal of Nuclear Science and Technology. 1982;19(11):936-947.

- Kattan N, Thome JR, Favrat D. R-502 and two near-azeotropic alternatives: part I – in tube flow-boiling tests ASHRAE Trans. 1995.

- Dittus F, Boelter L. Heat transfer in automobile radiators of the tubular type. International Communications in Heat and Mass Transfer. 1985;12(1):3-22.

- Skelland AHP, Leung LS. Power consumption in a scraped heat exchanger. Br Chem Eng. 1962;45(7):264-267.

- Trommelen A, Beek W. The mechanism of power consumption in a Votator†-type scraped-surface heat exchanger. Chemical Engineering Science. 1971;26(12):1977-1986.

- Leung LS. Power consumption in scraped surface heat exchangers. Trans Inst Chem Eng. 1967;45(7):T179-T181.

- Trommelen AM. Physical aspects of scraped surface heat exchanger. Thesis, Technische Hogeschool, Delft. 1970.

- Qin F, Chen XD, Ramachandra S, et al. Heat transfer and power consumption in a scraped-surface heat exchanger while freezing aqueous solutions. Separation and Purification Technology. 2006;48(2):150-158.