Research Article - Journal of Food Technology and Preservation (2017) Volume 1, Issue 1

Study of the flavor volatiles in double-fried pork: Identification and analysis of their changes during frozen storage using headspace solid-phase microextraction and gas chromatography-mass spectrometry

Aiquan Jiao1,2,3, Xueming Xu2,3, Zhengyu Jin1,2,3*1State Key Laboratory of Food Science and Technology, Jiangnan University, Wuxi, 214122, PR China

2School of Food Science and Technology, Jiangnan University, Wuxi, 214122, PR China

3Synergetic Innovation Center of Food Safety and Nutrition, Jiangnan University, Wuxi, 214122, PR China

- *Corresponding Author:

- Zhengyu Jin

Food Science

State Key Laboratory of Food Science and Technology

Jiangnan University

PR China

Tel: +0086-510-85919189

E-mail: pcenter@jiangnan.edu.cn

Accepted date: April 04, 2017

Citation: Jiao A, Xu X, Jin Z. Study of the flavor volatiles in double-fried pork: Identification and analysis of their changes during frozen storage using headspace solid-phase microextraction and gas chromatography-mass spectrometry. J Food Technol Pres. 2017;1:47-55

Abstract

The flavor volatiles present in double-fried pork and their changes during frozen storage were investigated for the first time using head space-solid phase micro extraction (HS-SPME) and gas chromatography-mass spectrometry (GC-MS) methods. We identified total 91 types of volatiles including eighteen heterocyclic compounds (6.9%), fifteen alcohols (11.4%), thirteen aldehydes (51.2%), twelve esters (7.7%), eleven hydrocarbons (2.3%), seven sulfur compounds (9.4%), six ketones (7.0%), and four acids (1.4%). Both the content and the types of heterocyclics and esters significantly increased post cooking. Principal component analysis showed three principal components (PC) with the first one (PC1) representing majority of the flavor compounds (73.65%), identified as the characteristic flavors. We could distinguish between the samples with different frozen time from the distinct flavors: (i) 1-penten-3-ol, 3-methyl-1-butanol and octanal in one month frozen samples; (ii) nonanal, trans-2,4-decadienal, and phenylethyl alcohol in 2-3 months frozen samples, and (iii) hexanal and ethanol in the 5-6 months frozen samples.

Keywords

Double-fried pork, Volatile compounds, GC-MS analysis, frozen storage, PCA analysis.

Introduction

Pork, an important nutritional ingredient in the human diet, is rich in high-quality protein, essential fatty acids, and some vital trace elements such as calcium, phosphorus, iron, and thiamin [1]. Double-fried cooking, a characteristic processing technique for pork in China, has also been popular all over the world in recent years. Flavor of double-fried pork is considered as the primary palatability factor and is shown to be of great importance. The number of flavor volatile compounds, identified in the extracts of livestock and poultry meat, is over one thousand; those include aldehydes, ketones, esters, ethers, alkanes, alkenes, alcohols, carboxylic acid, and some heterocyclic compounds (oxygen, nitrogen and sulfur) [2]. The flavor of pork is not only influenced by breed, age, gender, feed environment of animals, but also affected by the physical and chemical factors such as processing methods (cooking, baking, or fermentation process), storage conditions, or the addition of different pickled formulations and spices [3,4]. Many researchers have studied the flavor of pork processed by different methods, for example, Zeng et al. [5] investigated the compositions of flavor compounds of pork, boiled in clear soup or braised in soy sauce; Chen et al. [6] studied the aroma of pork slices cooked in fermented mustard greens; Du [7] determined the flavor of fermented pork, while Qin et al. [8] investigated the variations of aroma compounds in roasted Rongchang pork under different temperature conditions. However, little information available on the flavor compounds of pork, processed by double-fried cooking. Therefore, the objective of this study was to identify the flavor compounds in double-fried pork and to investigate the changes in these flavors during frozen storage. To the best of our knowledge, this is the first report, where the flavor volatiles present in double-fried pork were extracted using head spacesolid phase micro extraction (HS-SPME) technique -a rapid, inexpensive, and solvent-free method for extracting volatile and semi-volatile [9].

Materials and Methods

Materials

Streaky pork, green onion, ginger, garlic and pepper were purchased from local market. Thick broad-bean sauce, flavor bean sauce and mushroom sauce were supported by PIXIAN Watereress Co., Ltd. (Sichuan, China), Chuannan Fermentation Co., Ltd. (Sichuan, China), and Foshan Haitian Flavoring and Food Co., Ltd. (Guangdong, China), respectively. Salt (food grade), white granulated sugar, and rice wine were purchased from Jiangsu Salt Industry Group Co., Ltd. (Jiangsu, China), Hangzhou Luzhibao Food Co., Ltd. (Zhejiang, China), and Huzhou Laoheng Fermentation Co., Ltd. (Zhejiang, China), respectively. Ajinomoto was purchased from Taitaile Food Co., Ltd. (Shanghai, China). All other chemicals were of analytical grade.

Sample preparation

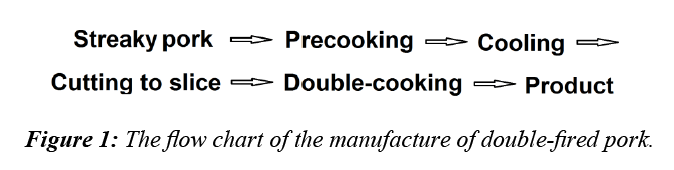

Figure 1 presents the flow chart of preparing double-fried pork. Following the preliminary practice of meat processing, water was boiled with powdered ginger and garlic, scallions, pepper, rice wine and salt for approximately 30 s. The streaky pork was rolled to 60-80% mature so that chopsticks can be inserted through into the pork, taken out to form “lamp socket” more easily, the key is to have a little meat and a little blood in the middle area), and cooled in the refrigerator for 3 min (while high temperature facilitates the separation of fat and lean meat, low temperature is not conducive for preparing pork slices). Finally, the cooked pork was cut down to fillet (~5 cm long, 3 cm wide and 0.2 cm thick). The double-fried cooking of pork was carried out in an induction cooker at 180°C for 3.5 min. A little vegetable oil was poured on the pre-heated pan (40% heating); when the oil temperature reached a certain degree (90°C), the precooked pork was put into the pan, and stir-fried for 1.5 min (the oil temperature was maintained at about 90°C by keeping the heating temperature at 180°C for 1.5 min. The pork fat curled up, forming “lamp socket”. At this point, thick broad-bean sauce and flavor bean sauce were added and cooked for 1 min. Next, green onion, ginger, garlic, white granulated sugar, Ajinomoto, mushroom sauce and rice wine were added and again cooked for 1 min to obtain the final product of doublefried pork, which was stored at -20°C for further analysis.

Headspace solid-phase microextraction (HS-SPME) for the volatiles of double-fried pork

A 75 μm carboxen/poly (dimethylsiloxane) (CAR/PDMS) coated fiber (Supelco, Inc., Bellefonte, PA, USA) was used for the HS-SPME of the volatile compounds from the doublefried pork sample. Each pork sample (7 g) was cut, mashed and put into a 15 ml glass bottle. The glass bottle was then tightly capped with a silicon septum. The samples were equilibrated at 65°C for 10 min, and the volatile compounds were extracted at the same temperature (65°C) with stirring for 30 min in a multipurpose sampler with SPME capability (MPS2, Gerstel, Germany). Immediately after extraction, the fiber was inserted into the injection port of GC (gas chromatography) for 5 min at 250°C (in split mode) to desorb the analytes. All experiments were carried out in duplicate.

Gas chromatography-mass spectrometry (GC-MS) analysis for the volatiles of double-fried pork

Analysis of the flavor compounds of double-fried pork was performed on a 1200 L GC/MS-MS system (Finnigan Co., USA) equipped with a 1079 middle injector and a mass selective detector (MSD). The MSD was used to identify unknown compounds. The separation of volatile and semivolatile compounds was performed using a fused silica capillary column (specification: 50 m × 0.32 mm i.d., coated with BPX-5 at 0.5 μm film thickness, SGE Ltd.). The temperature of both the injector and the detector was set at 250°C. Following was the GC program for identification: an oven temperature of 40°C held for first 2 min, then heating to 100°C (5°C/min) held for 0 min, and finally, heating to 250°C (10°C/min) held for 20 min. Helium was used as the carrier gas with a flow rate of 70 μl/ min and a split ratio of 50 ml/min. Mass spectra were recorded in the centroid scan mode at an ionization voltage of 70 eV, an emission current of 50 μA for filament, and an ion source temperature of 200°C. Electron impact (EI) mass spectra were recorded in the 33-450 amu range with a scan time of 0.400 s.

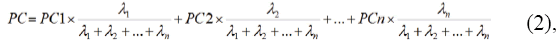

Volatiles were identified by comparing their mass spectra with the mass spectra from MS libraries (NIST/WILEY/REPLIB/ MAINLIB) [10]. The volatiles were identified according to the matched-degree as well as the purity (>800). The relative percentage content of each compound was calculated by area normalization method. Principal component analysis (PCA) was performed to determine the respective contribution of various flavor compounds on the total aroma, and the synthesis score of principal components was calculated as follows:

Where PCn is the principal component n, fn is the score of PCn, λn is the characteristic value of PCn, and PC is the total score or synthesis score.

Statistical analysis

Statistical analysis was performed using SPSS 17.0 for Windows (SPSS Inc., Chicago, Illinois USA). The results were analyzed by performing the analysis of variance (ANOVA) procedure. Correlation analysis was performed to determine the significant differences in the double-fried pork samples with different frozen storage times [11].

Results and Discussions

Tables 1 and 2 show that the amount of the main flavor compounds (such as aldehydes, hydrocarbons, and alcohols) is higher in raw pork than those in double-fried pork. However, we found that the relative amount of some trace volatiles (ketones, esters, acids, heterocyclics and sulfurs), especially the esters and heterocyclics, in double-fried pork increased significantly. Moreover, the types of the volatiles of esters, heterocyclics, sulfurs increased in pork after cooking, while other flavor substances reduced in the number of species. The largest changes in relative amounts occurred in the ester and heterocyclic contents. The relative content of esters dramatically increased from 0.21% to 7.74% with increase in the types from six to twelve, while the heterocyclic content increased from 0.36% to 6.87% with eighteen types. Furthermore, the aroma of boiled specimens was soft and downy to some extent, mainly exhibiting a flavor profile comprising of grass aroma, fat aroma and fruit aroma. On the other hand, the aroma of cooked specimens was nutty, butyric, fruity, and burnt. During the frozen storage processing, we did not find any significant changes in the relative contents and types of volatiles in double-fried pork. Among heterocyclic compounds, we found mainly furans, pyrazines and pyrroles in double-fried pork. Furans contribute grain fragrant and sweet smell to the overall aroma of double-fried pork. The furans, we identified in the double-fried pork, were mainly 2-amyl furan, 2-acetyl furan, furfural and furfuryl alcohol. Pyrazines, found in double-fried pork, are mainly alkyl pyrazines. It forms in the Strecker degradation, with dicarbonyl compounds and amino acids forming alpha amino ketones and alpha amino ketones through condensation and oxidation, forming pyrazine. The threshold of methyl pyrazine is relatively high (>1 × 10-6 g/g) with little impact on pork flavor. However, if one or more of the methyl group is replaced by the ethyl, the corresponding smell thresholds will be greatly reduced with important effect to the flavor of food. In this study, 2-ethyl-5-methyl pyrazine, 2-ethyl- 6-methyl pyrazine, 2,5-dimethyl-3-ethyl pyrazine and 2-methyl- 3-ethyl pyrazine in double-fried pork had smell thresholds and significantly affected the flavor. Pyrrole compounds, similar in structure of furans as well as their formation mechanism, is mainly generate from the Maillard reaction. It is formed via 3-deoxidization ketone sugar reacted with amino compounds and ammonia or after dehydration condensation and cyclization reaction. 2-Acetyl pyrrole has grains aroma, but alkyl pyrrole and acyl pyrrole will produce bad flavor for double-fried pork.

Table 1: Result of GC-MS analysis for the relative content (%) of volatile flavors of double-fried pork during cooking process and frozen storage.

| Number | Volatile compounds Aldehydes | A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Pentanal | 2.500 | 2.251 | 2.006 | 2.265 | 2.132 | 2.238 | 2.284 | 2.216 |

| 2 | Butanal, 3-methyl- | nd | 2.926 | 3.168 | 2.899 | 3.322 | 2.879 | 2.934 | 2.949 |

| 3 | Hexanal | 46.665 | 37.632 | 37.159 | 37.717 | 38.001 | 37.829 | 37.776 | 37.883 |

| 4 | 2,4 Pentadienal | 1.817 | nd | nd | nd | nd | nd | nd | nd |

| 5 | Heptanal | 2.401 | 0.691 | 0.736 | 0.668 | 0.753 | 0.726 | 0.772 | 0.719 |

| 6 | 2-Hexenal | 0.063 | nd | nd | nd | nd | nd | nd | nd |

| 7 | Octanal | 1.848 | 0.631 | 0.649 | 0.592 | 0.561 | 0.662 | 0.661 | 0.672 |

| 8 | 2-Heptenal, (Z)- | 0.589 | nd | nd | nd | nd | nd | nd | nd |

| 9 | Nonanal | 3.421 | 2.252 | 2.139 | 2.366 | 2.347 | 2.402 | 2.306 | 2.282 |

| 10 | 2 Octenal | 0.466 | 0.298 | 0.269 | 0.113 | 0.109 | 0.101 | 0.097 | 0.088 |

| 11 | Benzaldehyde | nd | 1.292 | 1.269 | 1.402 | 1.438 | 1.532 | 1.623 | 1.701 |

| 12 | 2-Nonenal, (E)- | nd | 0.099 | nd | nd | nd | nd | nd | nd |

| 13 | Benzeneacetaldehyde | nd | 1.816 | 1.944 | 1.809 | 1.854 | 1.914 | 1.918 | 1.859 |

| 14 | Decanal | 0.052 | nd | nd | nd | nd | nd | nd | nd |

| 15 | Octadecanal | 0.016 | nd | nd | nd | nd | nd | nd | nd |

| 16 | d-Myrtenal | 0.049 | nd | nd | nd | nd | nd | nd | nd |

| 17 | Z-Citral | 0.377 | 0.501 | 0.543 | 0.467 | 0.475 | 0.502 | 0.484 | 0.457 |

| 18 | E-Citral | 0.415 | 0.739 | 0.792 | 0.673 | 0.657 | 0.715 | 0.651 | 0.624 |

| 19 | 2,4-Decadienal, (E,E) | 0.059 | 0.159 | 0.164 | 0.179 | 0.168 | 0.172 | 0.165 | 0.159 |

| Alcohols | |||||||||

| 20 | Ethanol | 0.758 | 2.02 | 2.11 | 2.36 | 2.85 | 3.754 | 4.265 | 4.195 |

| 21 | Carveol, dihydro-, cis- | nd | 1.397 | 1.379 | 1.210 | 1.143 | 1.154 | 1.162 | 1.166 |

| 22 | 2-Propen-1-ol | 0.043 | 1.381 | 1.352 | 1.326 | 1.039 | 1.034 | 1.042 | 1.025 |

| 23 | 1-Butanol | 0.205 | 0.182 | 0.237 | 0.255 | 0.243 | 0.241 | 0.237 | 0.319 |

| 24 | 1-Penten-3-ol | 0.117 | 0.231 | 0.226 | 0.168 | 0.124 | 0.154 | 0.169 | 0.176 |

| 25 | 1,8-Cineole | 1.589 | 0.388 | 0.388 | 0.343 | 0.288 | 0.276 | 0.253 | 0.296 |

| 26 | 1-Butanol, 3-methyl- | nd | 0.701 | 0.679 | 0.519 | 0.466 | 0.419 | 0.503 | 0.685 |

| 27 | 3-Buten-1-ol, 3-methyl- | 0.063 | nd | nd | nd | nd | nd | nd | nd |

| 28 | 1-Pentanol | 4.492 | 1.371 | 1.319 | 1.299 | 1.581 | 1.657 | 1.391 | 1.310 |

| 29 | 1-Hexanol | 0.979 | 0.658 | 0.450 | 0.524 | 0.381 | 0.2 | 0.148 | 0.138 |

| 30 | 1-Octen-3-ol | 2.938 | 1.932 | 1.858 | 1.881 | 2.001 | 1.944 | 1.848 | 1.907 |

| 31 | 1-Heptanol | 0.688 | nd | nd | nd | nd | nd | nd | nd |

| 32 | Thujyl alcohol | 0.156 | nd | nd | nd | nd | nd | nd | nd |

| 33 | 2-Decanol | 0.034 | nd | nd | nd | nd | nd | nd | nd |

| 34 | Cyclohexanol, 1-methyl-4-(1-methyletheny | 0.126 | nd | nd | nd | nd | nd | nd | nd |

| 35 | p-Menth-8-en-1-ol, stereoisomer | 0.084 | nd | nd | nd | nd | nd | nd | nd |

| 36 | 2-Cyclohexen-1-ol,1-methyl-4-(1-methylethyl)-, trans- | 0.098 | nd | nd | nd | nd | nd | nd | nd |

| 37 | 1-Hexanol, 2-ethyl- | 0.067 | nd | nd | nd | nd | nd | nd | nd |

| 38 | Linalool | 0.207 | 0.247 | 0.304 | 0.225 | 0.263 | 0.317 | 0.266 | 0.266 |

| 39 | 1-Octanol | 0.506 | 0.152 | 0.141 | 0.134 | 0.128 | 0.120 | 0.117 | 0.165 |

| 40 | 2,3-Butanediol | 0.093 | nd | nd | nd | nd | nd | nd | nd |

| 41 | Terpinen-4-ol | 0.373 | 0.210 | 0.170 | 0.054 | 0.093 | 0.102 | 0.086 | 0.083 |

| 42 | 2-Octen-1-ol-(E) | 0.418 | 0.189 | 0.138 | 0.105 | 0.091 | 0.085 | 0.064 | 0.058 |

| 43 | alpha-Terpineol | 0.204 | nd | 0.146 | nd | nd | nd | nd | nd |

| 44 | Borneol | 0.115 | nd | nd | nd | nd | 0.07 | nd | nd |

| 45 | Nerol | 0.225 | nd | nd | nd | nd | nd | nd | nd |

| 46 | Geraniol | 0.329 | nd | nd | nd | nd | nd | nd | nd |

| 47 | Phenylethyl Alcohol | 0.130 | 0.353 | 0.322 | 1.095 | 0.827 | 0.156 | 0.126 | 0.130 |

| 48 | Beta-Fenchyl alcohol | nd | nd | nd | nd | 0.09 | nd | nd | nd |

| Hydrocarbons | |||||||||

| 49 | Octane | 0.051 | nd | nd | nd | nd | nd | nd | nd |

| 50 | Heptane, 2,4-dimethyl- | 0.057 | nd | nd | nd | nd | nd | nd | nd |

| 51 | Decane | 0.031 | nd | nd | nd | nd | nd | nd | nd |

| 52 | Undecane | nd | nd | nd | nd | nd | nd | nd | nd |

| 53 | Tridecane | nd | nd | nd | nd | nd | nd | nd | 0.094 |

| 54 | Toluene | 3.989 | 0.405 | 0.427 | 0.526 | 0.581 | 0.665 | 0.956 | 0.840 |

| 55 | Camphene | 0.222 | 0.826 | 1.073 | 0.673 | 0.391 | 0.146 | 0.134 | 0.211 |

| 56 | a-Curcumene | nd | nd | 0.157 | nd | nd | nd | nd | nd |

| 57 | Styrene | nd | 0.112 | 0.107 | 0.102 | 0.096 | 0.078 | 0.056 | 0.08 |

| 58 | Camphene hydrate | 0.097 | nd | nd | nd | nd | nd | nd | nd |

| 59 | Sabinene | 0.135 | nd | nd | nd | nd | nd | nd | nd |

| 60 | Benzene, ethyl- | 0.123 | 0.068 | 0.070 | 0.065 | 0.058 | 0.052 | 0.064 | 0.054 |

| 61 | p-Xylene | 0.076 | 0.078 | 0.074 | 0.070 | 0.071 | 0.066 | 0.062 | 0.068 |

| 62 | beta.-Pinene | 0.113 | nd | nd | nd | nd | nd | nd | nd |

| 63 | alpha.-Copaene | 0.083 | nd | nd | nd | nd | nd | nd | nd |

| 64 | l-Phellandrene | 0.030 | 0.171 | 0.162 | 0.167 | 0.156 | 0.155 | 0.168 | 0.152 |

| 65 | beta.-Phellandrene | nd | 0.825 | 0.731 | 0.538 | 0.533 | 0.156 | 0.217 | 0.277 |

| 66 | beta.-Myrcene | 0.257 | 0.700 | 0.136 | 0.141 | 0.098 | 0.074 | 0.068 | 0.073 |

| 67 | 1,3,6-Octatriene, 3,7-dimethyl-, (Z) | nd | 0.143 | nd | nd | nd | nd | nd | nd |

| 68 | trans-Caryophyllene | nd | 0.161 | nd | nd | nd | nd | nd | nd |

| 69 | Cyclohexene, 1-methyl-4-(1-methylethylid | 0.089 | nd | nd | nd | nd | nd | nd | nd |

| 70 | .alpha.-Terpinene | 0.056 | nd | nd | nd | nd | nd | nd | nd |

| 71 | l-Limonene | 0.312 | 0.541 | 0.425 | 0.494 | 0.455 | 0.502 | 0.607 | 0.509 |

| 72 | gamma.-Terpinene | 0.083 | nd | nd | nd | nd | nd | nd | nd |

| 73 | Benzene, 1-methyl-3-(1-methylethyl)- | 0.068 | nd | nd | nd | nd | nd | nd | nd |

| 74 | o-Cymene | 0.089 | nd | nd | nd | nd | nd | nd | nd |

| 75 | Cyclopentane, (2-methylpropylidene)- | 0.100 | nd | nd | nd | nd | nd | nd | nd |

| 76 | Limonene oxide | 0.135 | nd | nd | nd | nd | nd | nd | nd |

| 77 | beta.-Bisabolene | 0.252 | nd | nd | nd | nd | nd | nd | nd |

| 78 | Cyclohexene, 3-(1,5-dimethyl-4-hexenyl)- | 0.159 | nd | nd | nd | nd | nd | nd | nd |

| 79 | Benzene, 1-(1,5-dimethyl-4-hexenyl)-4-me | 0.252 | nd | nd | nd | nd | nd | nd | nd |

| Ketones | |||||||||

| 80 | Acetone | nd | 3.704 | 3.682 | 3.655 | 3.469 | 3.124 | 2.766 | 2.183 |

| 81 | 2-Propanone, 1-hydroxy- | nd | 0.256 | 0.283 | 0.246 | 0.275 | 0.297 | 0.313 | 0.355 |

| 82 | 2-Heptanone | 0.176 | nd | nd | nd | nd | nd | nd | nd |

| 83 | 2-Butanone, 3-hydroxy- | 0.251 | 0.172 | 0.189 | 0.197 | 0.175 | 0.179 | 0.179 | 0.231 |

| 84 | 1-Octen-3-one | 0.077 | nd | nd | nd | nd | nd | nd | nd |

| 85 | 4-Octen-3-one | 0.083 | nd | nd | nd | nd | nd | nd | nd |

| 86 | 2,3-Octanedione | 2.928 | 2.529 | 2.595 | 2.665 | 2.732 | 2.714 | 2.803 | 2.842 |

| 87 | 5-Hepten-2-one, 6-methyl- | 0.204 | 0.205 | 0.232 | 0.251 | 0.379 | 0.401 | 0.366 | 0.419 |

| 88 | Bicyclo[2.2.1]heptan-2-one, 1,7,7-trimet | 0.075 | nd | nd | nd | nd | nd | nd | nd |

| 89 | p-menth-1-en-3-one | 0.303 | nd | nd | nd | nd | nd | nd | nd |

| 90 | Xanthoxylin | 0.353 | nd | nd | nd | nd | nd | nd | nd |

| 91 | Ethanone, 1-(2-hydroxy-4,6-dimethoxyphen | nd | 0.117 | nd | 0.107 | nd | nd | nd | nd |

| 92 | 2-Cyclohexen-1-one, 2-methyl-5-(1-methyl) | nd | nd | nd | nd | 0.335 | nd | nd | nd |

| 93 | 2-Propanone, 1-(acetyloxy)- | nd | nd | nd | nd | nd | nd | 0.087 | 0.095 |

| Esters | |||||||||

| 94 | Formic acid, 2-propenyl ester | nd | 0.733 | nd | nd | nd | nd | nd | nd |

| 95 | Methyl laurate | nd | nd | nd | nd | nd | nd | nd | 0.097 |

| 96 | 2,2-Dimethyl-6-oxoheptanoic acid methyl ester | nd | nd | nd | nd | nd | nd | nd | 0.077 |

| 97 | 1-Butanol, 3-methyl-, acetate | nd | 0.071 | 0.064 | 0.060 | 0.051 | 0.045 | 0.043 | 0.047 |

| 98 | Hexanoic acid, ethyl ester | nd | 0.110 | 0.201 | 0.168 | 0.309 | 0.351 | 0.269 | 0.252 |

| 99 | Propanoic acid, 2-hydroxy-,ethyl ester | 0.069 | 0.172 | 2.045 | 2.407 | 2.284 | 2.248 | 2.404 | 2.488 |

| 100 | Octanoic acid, ethyl ester | nd | 0.065 | nd | nd | nd | nd | nd | nd |

| 101 | Linalyl acetate | nd | 2.687 | 2.428 | 2.401 | 2.359 | 2.363 | 2.454 | 2.428 |

| 102 | Propanoic acid, 2-methyl-, 3,7-dimethyl- | nd | 0.713 | 0.72 | 0.693 | 0.801 | 0.776 | 0.719 | 0.721 |

| 103 | Benzoic acid, methyl ester | nd | 0.159 | 0.242 | 0.152 | 0.169 | 0.172 | 0.164 | 0.159 |

| 104 | 2(3H)-Furanone, dihydro- | nd | 0.191 | 0.382 | 0.231 | 0.465 | 0.325 | 0.372 | 0.368 |

| 105 | Benzoic acid, ethyl ester | nd | 2.552 | 2.683 | 2.646 | 2.776 | 2.808 | 2.683 | 2.641 |

| 106 | Benzeneacetic acid, ethyl ester | nd | 0.062 | 0.079 | 0.081 | 0.073 | 0.068 | 0.074 | 0.072 |

| 107 | Butanedioic acid, diethyl ester | nd | 0.221 | 0.219 | 0.223 | 0.213 | 0.216 | 0.215 | 0.218 |

| 108 | Acetic acid, butyl ester | 0.039 | nd | nd | nd | nd | nd | nd | nd |

| 109 | Acetic acid, cyano-, 2-ethylhexyl ester | 0.043 | nd | nd | nd | nd | nd | nd | nd |

| 110 | Glycerol 1,2-diacetate | 0.038 | nd | nd | nd | nd | nd | nd | nd |

| 111 | (3S)-1,3-Diacetoxy Butane(impure) | 0.015 | nd | nd | nd | nd | nd | nd | nd |

| 112 | 3,6-Octadecadiynoic acid, methyl ester | 0.008 | nd | nd | nd | nd | nd | nd | nd |

| Acids | |||||||||

| 113 | Acetic acid | 0.126 | 0.861 | 0.898 | 0.935 | 0.987 | 1.047 | 1.095 | 1.109 |

| 114 | Butanoic acid | nd | 0.201 | 0.198 | 0.192 | 0.183 | 0.187 | 0.184 | 0.179 |

| 115 | Pentanoic acid | 0.104 | nd | nd | nd | nd | nd | nd | nd |

| 116 | Hexanoic acid | 0.231 | 0.173 | 0.162 | 0.168 | 0.157 | 0.172 | 0.174 | 0.168 |

| 117 | Octanoic acid | 0.036 | nd | nd | nd | nd | nd | nd | nd |

| 118 | Nonanoic acid | 0.020 | nd | nd | nd | nd | nd | nd | nd |

| 119 | Decanoic acid | 0.022 | nd | nd | nd | nd | nd | nd | nd |

| 120 | Hexadecanoic acid | 0.087 | 0.198 | 0.186 | 0.191 | 0.182 | 0.186 | 0.197 | 0.198 |

| Heterocyclic compounds | |||||||||

| 121 | Furan, 2-ethyl- | nd | 0.558 | 0.553 | 0.562 | 0.545 | 0.554 | 0.531 | 0.488 |

| 122 | 2-Furancarboxaldehyde | nd | 0.536 | 0.704 | 0.806 | 0.903 | 0.929 | 0.943 | 0.901 |

| 123 | 2-Furanmethanol | nd | 0.817 | 0.831 | 0.811 | 0.904 | 0.907 | 0.921 | 0.935 |

| 124 | 2-Furanmethanol, 5-methyl- | nd | 0.077 | 0.072 | 0.079 | 0.071 | 0.068 | 0.071 | 0.057 |

| 125 | 2-Furancarboxaldehyde, 5-methyl- | nd | 0.101 | 0.122 | 0.137 | 0.148 | 0.189 | 0.191 | 0.194 |

| 126 | Furan, 2-pentyl- | 0.357 | 0.191 | 0.198 | 0.193 | 0.199 | 0.261 | 0.272 | 0.277 |

| 127 | Pyrazine, methyl- | nd | 0.669 | 0.648 | 0.633 | 0.679 | 0.646 | 0.668 | 0.714 |

| 128 | Pyrazine, ethyl- | nd | 0.098 | 0.086 | 0.091 | 0.096 | 0.092 | 0.085 | 0.088 |

| 129 | 2,5-dimethyl pyrazine | nd | 1.220 | 1.201 | 1.325 | 1.287 | 1.352 | 1.393 | 1.294 |

| 130 | Pyrazine, 2,6-dimethyl- | nd | 0.591 | 0.536 | 0.573 | 0.552 | 0.529 | 0.598 | 0.532 |

| 131 | Pyrazine, 2-ethyl-3-methyl- | nd | 0.280 | 0.268 | 0.275 | 0.272 | 0.261 | 0.246 | 0.237 |

| 132 | Pyrazine, 2-ethyl-5-methyl- | nd | 0.073 | 0.071 | 0.062 | 0.060 | 0.057 | 0.053 | 0.051 |

| 133 | Pyrazine, 2-ethyl-6-methyl- | nd | 0.078 | 0.072 | 0.069 | 0.068 | 0.061 | 0.044 | 0.057 |

| 134 | Pyrazine, 3-ethyl-2,5-dimethyl- | nd | 0.201 | 0.193 | 0.189 | 0.191 | 0.186 | 0.173 | 0.182 |

| 135 | Pyrazine, trimethyl- | nd | 0.324 | 0.317 | 0.319 | 0.338 | 0.305 | 0.296 | 0.291 |

| 136 | Ethanone, 1-(1H-pyrrol-2-yl)- | nd | 0.554 | 0.518 | 0.505 | 0.548 | 0.402 | 0.432 | 0.472 |

| 137 | Ethanone, 1-(2-furanyl)- | nd | 0.316 | 0.324 | 0.341 | 0.295 | 0.268 | 0.226 | 0.228 |

| 138 | 1H-Pyrrole, 1-methyl- | nd | 0.189 | 0.184 | 0.176 | 0.175 | 0.162 | 0.154 | 0.151 |

| Sulphur-Containing Compounds | |||||||||

| 139 | 2-Propen-1-thiol | 5.637 | 4.15 | 4.291 | 4.186 | 3.925 | 3.893 | 3.911 | 3.868 |

| 140 | Disulfide, methyl 2-propenyl | 0.625 | 0.214 | 0.224 | 0.231 | 0.216 | 0.245 | 0.253 | 0.254 |

| 141 | Diallyl sulfide | 0.546 | 0.241 | 0.239 | 0.235 | 0.217 | 0.214 | 0.218 | 0.207 |

| 142 | Diallyl disulphide | 0.529 | 3.174 | 3.269 | 3.225 | 3.204 | 3.266 | 3.342 | 3.264 |

| 143 | Propanal, 3-(methylthio) | nd | 0.201 | 0.194 | 0.192 | 0.185 | 0.188 | 0.191 | 0.186 |

| 144 | Propane, 1-(ethynylsulfinyl)- | nd | 1.028 | 1.025 | 1.034 | 1.021 | 1.01 | 1.018 | 1.093 |

| 145 | Propanoic acid, 3-(acetylthio)-2-methyl- | nd | 0.389 | 0.394 | 0.401 | 0.358 | 0.362 | 0.322 | 0.317 |

| Others | |||||||||

| 146 | Benzene, chloro- | nd | nd | nd | nd | nd | 0.095 | 0.080 | 0.095 |

| 147 | Cyclotrisiloxane, hexamethyl- | 0.041 | nd | nd | nd | nd | nd | nd | nd |

| 148 | Cyclotetrasiloxane, octamethyl- | 0.378 | nd | nd | nd | nd | nd | nd | nd |

| 149 | Cyclopentasiloxane, decamethyl- | 0.096 | nd | nd | nd | nd | nd | nd | nd |

| 150 | Cyclohexasiloxane, dodecamethyl- | 0.161 | 0.088 | 0.123 | nd | 0.115 | nd | nd | nd |

| 151 | Hydroxylamine, O-decyl- | 0.026 | nd | nd | nd | nd | nd | nd | nd |

| 152 | 4-nitrophthalamide | 0.369 | nd | nd | nd | nd | nd | nd | nd |

| 153 | Silanediol, dimethyl- | 1.611 | nd | nd | nd | nd | nd | nd | nd |

| 154 | 1-Heptadecanamine | 0.041 | nd | nd | nd | nd | nd | nd | nd |

| 155 | Phenol, 3-methyl- | 0.026 | nd | nd | nd | nd | nd | nd | nd |

| 156 | N-benzylidene-dimethylammonium chloride | nd | 1.06 | 1.083 | nd | nd | nd | nd | nd |

| 157 | Phenol, 2,4-bis(1,1-dimethylethyl)- | nd | nd | nd | nd | nd | 0.439 | 0.209 | 0.165 |

| 158 | Phenol, 2,6-bis(1,1-dimethylethyl)-4-met | nd | 0.115 | 0.126 | nd | nd | nd | nd | nd |

| 159 | Phenol, 4-methyl- | nd | 0.111 | 0.048 | nd | nd | nd | 0.059 | 0.049 |

| 160 | Phenol, 4-methoxy- | nd | nd | nd | 0.055 | nd | nd | nd | nd |

| 161 | Caffeine | nd | 0.192 | nd | 0.173 | nd | nd | nd | nd |

| 162 | Phenol, 2-methyl-5-(1-methylethyl)- | nd | nd | 0.655 | nd | nd | nd | nd | nd |

| 163 | Thymol | nd | nd | 0.467 | nd | 0.224 | nd | nd | nd |

| 164 | Phenol, 2-methoxy- | nd | nd | 0.043 | nd | nd | nd | nd | nd |

| 165 | 1-Methoxy-2-propoxyethane | nd | nd | nd | nd | nd | nd | nd | 0.160 |

| 166 | 1,3-Dioxolane, 4,5-dimethyl-2-pentadecyl | nd | nd | nd | nd | nd | nd | nd | 0.082 |

A=Boiled specimens; B=Frozen storage for 0 month; C=Frozen storage for 1 month; D=Frozen storage for 2 month; E=Frozen storage for 3 month; F=Frozen storage for 4 month; G=Frozen storage for 5 month; H=Frozen storage for 6 month. nd: Not Detected.

Table 2: Relative content of volatile compounds of double-fried pork during cooking processing and frozen storage.

| A (%) (101) | B (%) (91) | C (%) (89) | D (%) (83) | E (%) (84) | F (%) (81) | G (%) (84) | H (%) (89) | |

|---|---|---|---|---|---|---|---|---|

| Aldehydes | 60.738 (15) | 51.287 ((13) | 50.838 (12) | 51.150 (12) | 51.817 (12) | 51.672 (12) | 51.671 (12) | 51.609 (12) |

| Alcohols | 15.037 (26) | 11.412 (15) | 11.219 (16) | 11.498 (15) | 11.608 (16) | 11.683 (16) | 11.677 (15) | 11.919 (15) |

| Hydrocarbons | 6.859 (24) | 4.030 (11) | 3.362 (10) | 2.776 (9) | 2.439 (9) | 1.894 (9) | 2.332 (9) | 2.358 (10) |

| Ketones | 4.45 (9) | 6.983 (6) | 6.981 (5) | 7.121 (6) | 7.365 (6) | 6.715 (3) | 6.514 (6) | 6.125 (6) |

| Esters | 0.212 (6) | 7.736 (12) | 9.063 (10) | 9.062 (10) | 9.500 (10) | 9.372 (10) | 9.397 (10) | 9.568 (12) |

| Acids | 0.626 (7) | 1.433 (4) | 1.444 (4) | 1.486 (4) | 1.509 (4) | 1.592 (4) | 1.650 (4) | 1.654 (4) |

| Heterocyclic compounds | 0.357 (1) | 6.873 (18) | 6.898 (18) | 7.146 (18) | 7.331 (18) | 7.229 (18) | 7.297 (18) | 7.149 (18) |

| Sulphur-Containing Compounds | 7.337 (4) | 9.397 (7) | 9.636 (7) | 9.504 (7) | 9.126 (7) | 9.178 (7) | 9.255 (7) | 9.189 (7) |

| Others | 2.749 (9) | 1.566 (5) | 2.545 (7) | 0.228 (2) | 0.339 (2) | 0.534 (2) | 0.348 (3) | 0.551 (5) |

A=Boiled specimens; B=Frozen storage for 0 month; C=Frozen storage for 1 month; D=Frozen storage for 2 month; E=Frozen storage for 3 month; F=Frozen storage for 4 month; G=Frozen storage for 5 month; H=Frozen storage for 6 month.

Apart from heterocyclic compounds, esters also increased significantly. We found that post cooking, the relative contents of esters as well as their types significantly increased from 0.212% to 7.736%. However, we did not find ethyl caproate, ethyl methyl benzoic acid, benzoic acid, benzene acetic acid ethyl ester, 4-hydroxy butyric acid lactone, linalyl acetate, isobutyric acid orange flower ester in the boiled specimens, but found in the cooked specimens, indicating that these important flavor compounds were formed during the process of cooking, influencing the flavor of double-fried pork. Most of these compounds have a pleasant aroma of fruits and flowers; some have elegant and sweet, pure and fresh and powerful flavor. We performed PCA analysis for flavor volatile compounds of double-fried pork during frozen storage to determine the principal component of volatiles in them and to understand the influence of frozen storage processing on these compounds. We selected total 80 kinds of flavor compounds for double-fried pork with different frozen storage times; Table 3 shows the results of PCA. According to the characteristic value and variance contribution of the principal component (PC) we found that the cumulated variance contribution ratio of the first three PCs was 89.87%, and the average values of the first six PCs was more than 1. Moreover, according to the two principles of the determination of the numbers of PCs -cumulative variance contribution rates reaching up to 85% and the characteristic value higher than one -we chose three PCs (PC1, PC2, and PC3) with contribution rates of 73.65%, 9.91% , and 6.30%, respectively. Table 4 presents the PC factor loading matrix; there are many flavor compounds - including benzaldehyde, geranial, dihydrogen celery alcohol, 1-octene-3-alcohol, linalool, p-xylene, 3-hydroxy-2-butanone, 2,3-symplectic diketone, methyl heptene ketone, ethyl caproate, ethyl lactate, ethyl methyl benzoic acid, benzoic acid, furfural, furfuryl alcohol, 2-amyl furan, 2,6-dimethyl pyrazine, 3-ethyl- 2-2-acetyl methyl pyrazine, pyrrole, 2-acetyl furan, N-methyl pyrrole and allyl methyl sulfide - exerting very high loading in PC1. We found total of 63 volatile compounds positively related to PC1, including three aldehydes, twelve alcohols, seven hydrocarbons, ten esters, four ketones, three acids, seventeen heterocyclics, and seven sulfurs- the characteristic flavor compounds of double-fried pork. In addition, hexanal, nonanal, trans-2,4-sebacic olefin aldehyde and benzene ethanol had positive effect on PC2, whereas myrcene, caproic acid and 2-ethyl pyrazine had positive effect on PC3. In order to reflect the various compounds accounted for t