Research Article - Journal of Food Science and Nutrition (2025) Volume 8, Issue 3

Standardization and qualitative analysis of freeze-dried avocado fruit powder.

Geethu M*, Neethu M, Saji Gomez

Department of Post-Harvest Technology, College of Agriculture, Kerala Agricultural University, Thrissu, India

- Corresponding Author:

- Geethu M

Department of Post-Harvest Technology, - College of Agriculture, Kerala Agricultural University,

Thrissu,

India,

E-mail: geethumsasikumar@gmail.com

Received: 04-Apr-2024, Manuscript No. AAJFSN-24-134065; Editor assigned: 06-Apr-2024, AAJFSN-24-134065 (PQ); Reviewed: 20-Apr-2024, QC No. AAJFSN-24-134065; Revised: 08-Jul-2025, Manuscript No. AAJFSN-24-134065 (R); Published: 15-Jul-2025, DOI: 10.35841/AAJFSN.8.3.267

Citation: Geethu M, Neethu M, Gomez S. Standardization and qualitative analysis of freeze-dried avocado fruit powder. J Food Nutr Health. 2025;8(3):267.

Abstract

Avocado is a highly nutritive fruit crop rich in monounsaturated fatty acids, antioxidant and bioactive phytonutrients. The pattern of consumption of avocado is a concern due to its unique climacteric nature with immediate ripening along with high polyphenoloxidase enzyme, results in rapid deterioration. Freeze drying separates moisture in the product by sublimation under freezing temperature and vacuum condition. Thus it is suitable for thermolabile and oxidation sensitive foods like avocado. Fresh ripe avocado fruit pulp added with food additives like maltodextrin, tricalcium phosphate, EDTA and potassium sorbate improves and maintains the physical and chemical properties of the freeze dried avocado powder. Adequate packaging in LDPE laminated aluminium pouches with minimum exposure to air and light and storage conditions at low temperature enhance the shelf life with maintaining the quality for three months. Physical parameters such as hygroscopicity and colour value a* and b* increased while L value decreased during storage. Nutritive attributes like vitamin C, total fat and organoleptic quality decreased towards the end of storage but the effect of maltodextrin was significant in reducing the loss. Peroxide value, water activity and microbial population were increased with the end of storage which were also regulated with increased concentration of maltodextrin.

Keywords

Persea americana, Lyophilisation, Organoleptic, Maltodextrin, LDPE laminated aluminium pouch.

Introduction

Avocado (Persea americana Mill.) is a nutrient dense tropical fruit crop belonging to the family Lauraceae with Central America and Mexican origin. Its high composition of unsaturated fat to saturated fat similar to olive oil (6:1) especially with monounsaturated fatty acid as oleic acid and antioxidant properties makes it a preferable diet for health conscious population. One serving of avocado contributes 5 g Monounsaturated Fatty Acid (MUFA) with significant amount of oleic acid at 4.53 g/serving and 1 g Polyunsaturated Fatty Acid (PUFA) in addition to many bioactive phytonutrients with therapeutic effects. Unique climacteric nature of the fruit which starts to ripe immediately after harvest and high fat content which may easily oxidise result in challenges for preserving and consuming the fruit.

Even though its high nutritive value foster its demand in the global market recently avocado has been a matter of controversy due to its adverse environmental impact. Deforestation for the monocropping of avocado, high demand for water and the high carbon footprint during the post-harvest storage and transportation are the major concerns. The transportation and storage of raw material results in higher carbon footprint of fruits. Freeze drying extends the shelf life of the products and reduces the complexity in the transportation and storage of the fruit. Rybak, et al. reported that blanching of red bell pepper in water at 98°C for 3 minutes had shown good reduction in the carbon emission of freeze drying [1].

Freeze drying/lyophilisation is a process in which water is frozen, followed by its removal from the sample, initially by sublimation (primary drying) and then by desorption (secondary drying). During freeze drying, water is separated by sublimation under very low temperature (-40 to -80°C) and very low vacuum conditions. It results in dehydrated products with enhanced shelf life and protected qualities of fresh commodities. It dries the product by freezing the water into ice at low temperature and sublimize the moisture into vapour under vacuum. Thus it is highly suitable for thermally sensitive and oxidation sensitive foods like avocado [2].

Food additives are substances added to the food in order to maintain or improve its safety, freshness, taste, texture, or appearance, which do not possess any potential harmful effects on human health. Maltodextrin is a tasteless, odourless powder which is Generally Recognized as Safe (GRAS) food additive with the potential of enhancing solubility, bulking and freeflowing properties and reduces oxygen permeability. Ascorbic acid is added to food with the objective of reducing the enzymatic browning of avocado fruit slices due to its antioxidant effect. Tricalcium phosphate is a food grade anticaking agent which improves the flowability of high fat containing powders. EDTA is a chelating agent with the property of inhibiting the enzymatic and oxidative activities. Potassium sorbate is a water soluble preservative with antimicrobial acitivity.

The physical properties such as bulk density indicates the volume required to occupy the powder while solubility and hygroscopicity show the time required to reconstitute in solvent and the hydrophilic nature of the powder respectively. Nutritive and other quality parameters such as total phenols, total fat, peroxide value, water activity etc. indicate the acceptability of freeze dried avocado powder with extended shelf life. Freeze dried fruit powder retains thermolabile proteins, water soluble vitamins and antioxidant compounds. Even though there are chances for adverse effects on the food quality and attributes during grinding and drying at glass transition stage of freeze drying, it ensures value added products with extended shelf life, higher quality and acceptability [3].

Materials and Methods

The post-harvest management study of freeze dried avocado fruit powder was conducted in the department of post-harvest technology, Kerala Agriculture University, India during 2021-2022. Fresh and matured avocado fruits were collected from Idukki district, a high altitude region located at 1525 m above MSL in Kerala, the southernmost state in India.

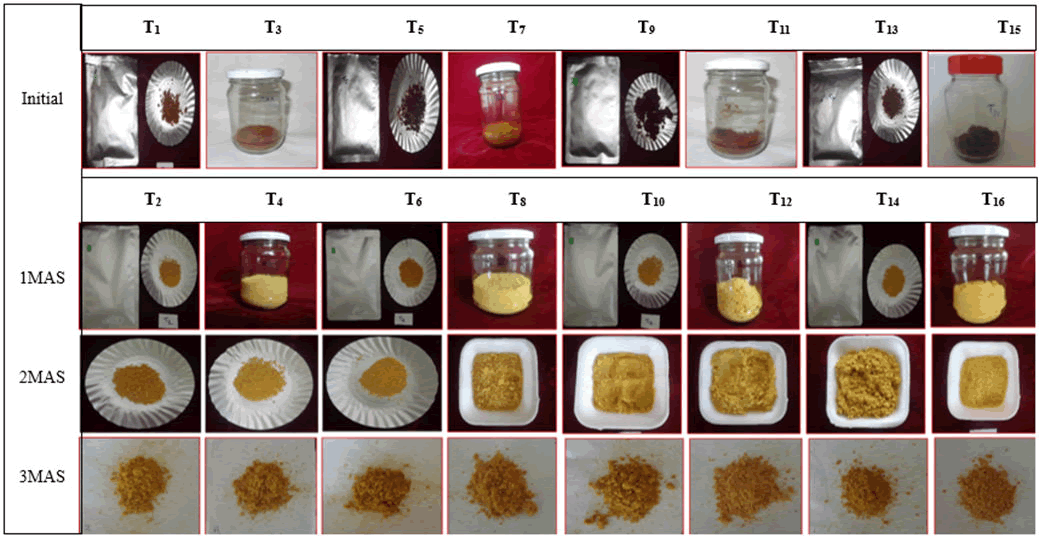

Ripe avocado fruits were washed, peeled, sliced and subsequently ground into pulp with minimum exposure to air and light. This pulp was added with different combinations of maltodextrin (2,3,4 and 5%) along with ascorbic acid (1%), tricalcium phosphate (0.15%), Ethylenediamine Tetraacetic Acid (EDTA) (0.05%) and potassium sorbate (0.05%). The prepared pulp was freeze dried in SP VirTis Benchtop K model freeze drier at -70°C and 25 milli torque vacuum for 36 hours to obtain freeze dried avocado powder. The dried produce was powdered and sieved. The powder obtained was packed in glass jars and LDPE laminated aluminium pouches (200 gauge) using continuous band sealer at 200°C and stored under ambient and refrigerated conditions for 3 months. Physical, biochemical, microbial and organoleptic observations were recorded at monthly intervals. There were 16 treatments replicated at thrice and the observations were statistically analysed based on a Completely Randomised Design (CRD) of experiments. Organoleptic scores were analysed using SPSS software with Kendall’s value. The treatments are given below (Figure 1).

- T1: Fruit pulp pre-treated with 2% maltodextrin packed in LDPE bags and stored at ambient temperature.

- T2: Fruit pulp pre-treated with 2% maltodextrin packed in LDPE bags and stored at refrigerated temperature.

- T3: Fruit pulp pre-treated with 2% maltodextrin packed in glass jars and stored at ambient temperature.

- T4: Fruit pulp pre-treated with 2% maltodextrin packed in glass jars and stored at refrigerated temperature.

- T5: Fruit pulp pre-treated with 3% maltodextrin packed in LDPE bags and stored at ambient temperature.

- T6: Fruit pulp pre-treated with 3% maltodextrin packed in LDPE bags and stored at refrigerated temperature.

- T7: Fruit pulp pre-treated with 3% maltodextrin packed in glass jars and stored at ambient temperature.

- T8: Fruit pulp pre-treated with 3% maltodextrin packed in glass jars and stored at refrigerated temperature.

- T9: Fruit pulp pre-treated with 4% maltodextrin packed in LDPE bags and stored at ambient temperature.

- T10: Fruit pulp pre-treated with 4% maltodextrin packed in LDPE bags and stored at refrigerated temperature.

- T11: Fruit pulp pre-treated with 4% maltodextrin packed in glass jars and stored at ambient temperature.

- T12: Fruit pulp pre-treated with 4% maltodextrin packed in glass jars and stored at refrigerated temperature.

- T13: Fruit pulp pre-treated with 5% maltodextrin packed in LDPE bags and stored at ambient temperature.

- T14: Fruit pulp pre-treated with 5% maltodextrin packed in LDPE bags and stored at refrigerated temperature.

- T15: Fruit pulp pre-treated with 5% maltodextrin packed in glass jars and stored at ambient temperature.

- T16: Fruit pulp pre-treated with 5% maltodextrin packed in glass jars and stored at refrigerated temperature.

Figure 1. Freeze dried avocado fruit powder during storage.

Note: T1: Pulp+MD (2%)+LDPE bags+AT; T2: Pulp+MD (2%) +LDPE bags+RT; T3: Pulp+MD (2%)+glass jars+AT; T4: Pulp+MD (2%)+glass jars+RT; T5: Pulp+MD (3%)+LDPE bags+AT; T6: Pulp +MD (3%)+LDPE bags+RT; T7: Pulp+MD (3%)+glass jars+AT; T8: Pulp+MD (3%)+glass jars+RT; T9: Pulp+MD (4%)+LDPE bags +AT; T10: Pulp+MD (4%)+LDPE bags+RT; T11: Pulp+MD (4%) +glass jars+AT; T12: Pulp+MD (4%)+glass jars+RT; T13: Pulp+MD (5%)+LDPE bags+AT; T14: Pulp+MD (5%)+LDPE bags+RT; T15: Pulp+MD (5%)+glass jars+AT; T16: Pulp+MD (5%)+glass jars+RT; MAS: Months after Storage

Pulp yield

Pulp yield was calculated from the weight of pulp obtained from the fruit with known weight, expressed in percentage of weight basis.

Percent of pulp=(Weight of pulp)/(Total weight of fruit)×100

Hygroscopicity

Standard quantity of freeze dried avocado fruit powder was spread over petridishes and keep in desiccator at room temperature until a constant weight. The weight increased per gram of powder solids indicated hygroscopicity.

Hygroscopicity (%)=(Gram of moisture absorbed)/(Gram of powder)×100

Colour values (L, a, b)

The colour properties of the freeze dried avocado fruit powder were determined using UV1800-2401PC colour analysis spectroscopy software, Shimadzu in terms of L* (light and dark), a* (red and green) and b* value (yellow and blue). L* represents the lightness to darkness (0-100), a* represents red (positive) and green (negative) colour, while b* represents yellow (positive) and blue (negative) colour.

Total soluble solids

Total soluble solids of freeze dried avocado fruit powder were measured using a digital refractometer (ATAGO, PAL-1, 0-53°Brix, Japan) and were expressed in °Brix.

Titratable acidity

Titratable acidity was measured according to AOAC by titrating against 0.1N sodium hydroxide. The value was expressed in per cent of malic acid which is the predominant acid present in the avocado fruit.

Titratable acidity (%)=(Titre value × Normality × Equivalent weight × Volume made up × 100)/(Weight of sample × Aliquot of sample × 1000)

Vitamin C

Vitamin C was measured according to AOAC, 3% metaphosphoric acid and titrate against 2,6-dichlorophenol indophenol dye.

Vitamin C (mg/100g)=(Dye factor × Titre value × Volume made up × 100)/(Weight of sample × Volume of aliquot)

Total fat

Total fat was distilled off completely in soxhlet apparatus with petroleum ether and determined the dry weight of sample.

Total fat (%)=(Weight of the fat (g))/(Weight of sample (g)) ×100

Peroxide value

Peroxide value of avocado oil or fat was determined by the titration method using solvent mixture and sodium thiosulphate according to AOAC.

Peroxide value (milliequivalent peroxide/kg sample)=(S × N × 100)/(Weight of fat (g))

S=Titre value of Na2S2O3 (mL) (Test-blank) and N=Normality of Na2S2O3

Water activity

Water activity (aw) is the ratio of partial vapour pressure of water in a food sample to the partial vapour pressure of pure water at a specific temperature. The water activity of the samples were measured using a water activity meter (AquaLab, Pre 40412, Decagon Devices, USA).

Enumeration of microbial population

Quantitative assay of microbial load was conducted using serial dilution spread plate technique suggested by Agarwal and Hasija [4].

Number of colony forming units (cfu/g of sample)=(Total no. of colony formed × Dilution Factor)/(Aliquot plated)

Organoleptic evaluation

Organoleptic evaluation provides the consumers’ sensory perception when ingesting a product with respect to their own smell, taste, texture and visual aspects. Sensory analysis was conducted using 9-point hedonic scale for sensory attributes viz. appearance, colour, flavour, odour, texture, taste, after taste and overall acceptability by a semi trained panel consisting of 15 members. Organoleptic scores were statistically analysed by Kendall’s Coefficient of Concordance (W) in SPSS software and were expressed in radar chart.

Results and Discussion

Freeze drying protects the volatile, non-volatile and thermolabile compounds which may contribute to the taste, flavour and nutritive attributes. Yield ratio of freeze dried powder to the fruit pulp was 38.57%.

Garcia, et al. reported that the yield of freeze dried avocado powder was about 30 to 35% of avocado pulp while Mujaffar and Dipnarine reported a yield of 17.10% freeze-dried avocado pulp from fresh pulp [5].

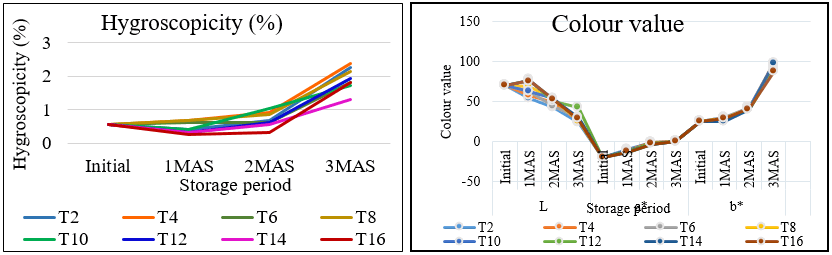

Hygroscopicity (%)

A gradual increase in hygroscopicity was seen during storage in all the pre-treated powder which indicated the absorption of moisture from the surroundings. Significantly lower values were observed in T16 after one (0.25%) and two (0.33%) months of storage and in T14 after three (1.31%) months of storage, which were pre-treated with higher concentration of maltodextrin (Figure 2). Jaya, et al. reported that the hygroscopicity of vacuum dried mango powder in the range of 5.3 to 10.3%, increased with decreasing amount of maltodextrin and tricalcium phosphate added [6].

Colour values (L, a*, b*)

Higher L value indicates the brightness of the powder which gets decreased during storage and the higher retention was noticed in T16, T14, T12 and T10 (values) with higher maltodextrin content.

Lower a* value noticed in T14 and T16 after one (-14.21 and -14.18) and two (-3.63) months of storage and in T12 (-0.38) after three months indicates the minimum change in colour of powder from greenish to reddish colour.

An increase in b* value was observed during storage and the lower b* value was noticed in T14 (25.30) after one month, in T12 (40.28) after 2 months and in T16 (86.46) after 3 months of storage, which indicated lower yellowish colour of avocado powder (Figure 2).

Figure 2. Effect of food additives on physical qualities of avocado powder during storage.

Note: T2: Pulp+MD (2%)+LDPE bags+RT; T4: Pulp+MD (2%) +glass jars+RT; T6: Pulp+MD (3%)+LDPE bags+RT; T8: Pulp +MD (3%)+glass jars+RT; T10: Pulp+MD (4%)+LDPE bags +RT; T12: Pulp+MD (4%)+glass jars+RT; T14: Pulp+MD (5%) +LDPE bags+RT; T16: Pulp+MD (5%)+glass jars+RT; MD: Maltodextrin; RT: Refrigerated Temperature; MAS: Months after Storage

Illeperuma and Nikapitiya reported a reduction in L* value from 15.50 to 14.20 in avocado slices packaged in MAP with different thickness, stored at 8°C and 90 ± 2% RH for 10 days [7]. Cenobio-Galindo, et al. reported that increase in a* indicated the loss of green colour and decrease in b* values associated with the loss of yellow colour of the avocado mesocarp [8]. Mujaffar and Dipnarine reported L*, a* and b* values for freeze dried avocado powder were 82.96 ± 0.59, -14.32 ± 0.02 and 60.38 ± 0.29 respectively [9].

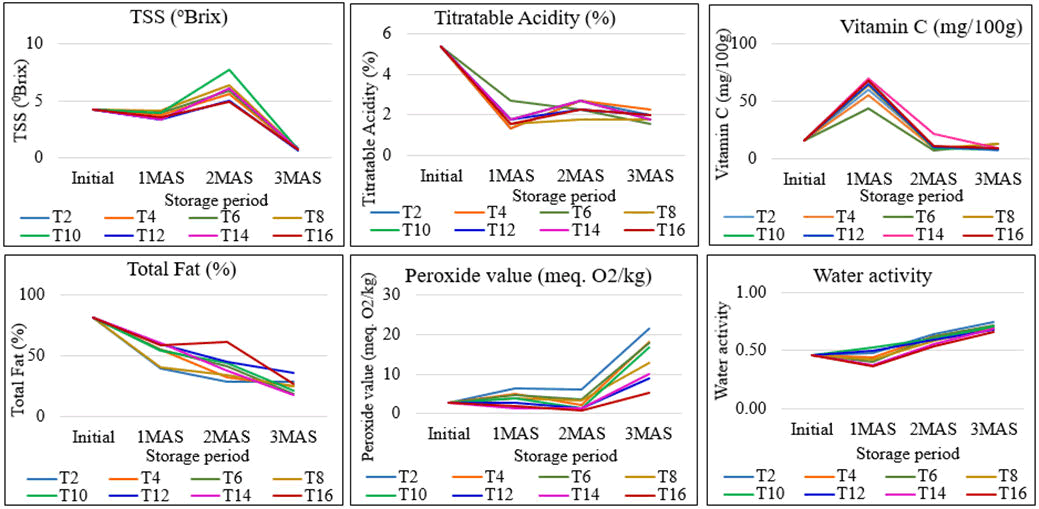

Total soluble solids (°Brix)

Total soluble solids of freeze dried avocado powder before storage was 4.25°Brix. Significantly higher TSS values were noticed in T14 (4.13°Brix) and T16 (7.70°Brix) after one and two months of storage, respectively (Figure 3) [10].

Figure 3. Effect of food additives on biochemical qualities of avocado powder during storage.

Note: T2: Pulp+MD (2%)+LDPE bags+RT; T4: Pulp+MD (2%) +glass jars+RT; T6: Pulp+MD (3%)+LDPE bags+RT; T8: Pulp +MD (3%)+glass jars+RT; T10: Pulp+MD (4%)+LDPE bags +RT; T12: Pulp+MD (4%)+glass jars+RT; T14: Pulp+MD (5%) +LDPE bags+RT; T16: Pulp+MD (5%)+glass jars+RT; MD: Maltodextrin; RT: Refrigerated Temperature; MAS: Months after Storage

Dilrukshi and Senarath reported that TSS of fresh smoothie powder added with maltodextrin was 22.27°Brix and freeze drying reduced it to 12.33°Brix by decreasing the moisture content [11].

Titratable acidity

Titratable acidity varied without any significant difference among the treatments throughout the storage. It was observed that initial content of titratable acidity in the freeze dried avocado powder was 5.36%, which decreased towards end of storage (Figure 3) [12].

Mujaffar and Dipnarine observed an increase in acidity of freeze dried avocado powder over 12 weeks of storage which might develop bitter taste in the powder. Chauhan and Singh reported a similar result as decrease in titratable acidity of freeze dried avocado powder with the addition of maltodextrin [13].

Vitamin C (mg/100g)

From an initial value of 15.73 mg/100g vitamin C content in freeze dried avocado powder decreased during storage. After one month of storage significantly higher vitamin C content was observed in T14 (70.00 mg/100g), T10 (68.67 mg/100g) and T16 (68.00 mg/100g). After three months of storage, T8 (13.33 mg/100g) recorded significantly higher value (Figure 3).

Dilrukshi and Senarath reported that slight reduction (12.50%) of vitamin C in instant smoothie powder of avocado after freeze drying and Dantas, et al. reported that maltodextrin has preservative effect on bioactive compounds like ascorbic acid [14].

Total fat (%)

The initial total fat content of freeze dried avocado powder was 81.03%, which decreased to 58.31%, 59.44% and 60.43% in T16, T12 and T14 respectively after one month of storage with significant variation among treatments (Figure 3). Chauhan and Singh reported total fat content of 42.2 ± 0.22% in freeze dried butter fruit milk shake powder. Even though there are reports concluding that the fatty acid profile does not vary during freeze drying, Castaneda-Saucedo, et al. made a supportive observation that the freeze-drying process slightly decreases the fatty acid especially linoleic acid [15].

Peroxide value (meq O2/kg)

A decrease in peroxide value was noticed from an initial value of 2.77 meq O2/kg towards the end of storage. The lowest peroxide value was noticed in samples with higher maltodextrin content such as T14, T16, T12 and T10 which was evident for the lower rate of rancidity (Figure 3).

Peroxide value of freeze dried avocado powder increased during storage while high maltodextrin composition decreased the effect of temperature on the oxidation of the sample and regulate the peroxide activity [16].

Water activity

Water activity increased during storage with the absorption of moisture by the powder and significantly lower water activity during storage was observed in samples T14 and T16 with higher maltodextrin content (Figure 3).

Cortes-Rodríguez, et al. reported water activity of freeze dried avocado powder as 0.257. Mujaffar and Dipnarine reported an increase in the water activity of freeze dried avocado powder after 12 weeks of storage from 0.352 to 0.534 [17].

Microbial load (cfu/g)

Microbial load was not observed up to one month of storage. Yeast population was nil in all the samples during the storage. After two and three months of storage, lowest fungal count was recorded in T14 and T8 and bacterial count in T10 respectively (Table 1).

| Treatments | Initial | 1MAS | 2MAS | 3MAS | ||||||||

| Fungi | Yeast | Bacteria | Fungi | Yeast | Bacteria | Fungi | Yeast | Bacteria | Fungi | Yeast | Bacteria | |

| T2 | 0 | 0 | 0 | 0 | 0 | 0 | 2.67 | 0 | 9.83 | 3.33bc | 0 | 14.5 |

| T4 | 0 | 0 | 0 | 0 | 0 | 0 | 0.67 | 0 | 3.33 | 2.33bc | 0 | 6.33 |

| T6 | 0 | 0 | 0 | 0 | 0 | 0 | 4.67 | 0 | 2 | 8.67a | 0 | 7.83 |

| T8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4.5 | 0.33c | 0 | 8 |

| T10 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1.17 | 1.67bc | 0 | 1.67 |

| T12 | 0 | 0 | 0 | 0 | 0 | 0 | 2.67 | 0 | 3.3 | 5.00ab | 0 | 6.5 |

| T14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3.83 | 0.33c | 0 | 6.67 |

| T16 | 0 | 0 | 0 | 0 | 0 | 0 | 2.67 | 0 | 3 | 3.67bc | 0 | 6 |

| CD (0.05) | NS | NS | NS | NS | NS | NS | NS | NS | NS | 4.58 | NS | NS |

| Note: T1: Pulp+MD (2%)+LDPE bags+AT; T2: Pulp+MD (2%)+LDPE bags+RT; T3 : Pulp+MD (2%)+glass jars+AT; T4: Pulp+MD (2%)+glass jars+RT; T5: Pulp+MD (3%)+LDPE bags+AT; T6: Pulp+MD (3%)+LDPE bags+RT; T7: Pulp+MD (3%)+glass jars+AT; T8: Pulp+MD (3%)+glass jars+RT; T9 : Pulp+MD (4%)+LDPE bags+AT; T10: Pulp+MD (4%)+LDPE bags+RT; T11: Pulp+MD (4%)+glass jars+AT; T12: Pulp+MD (4%) +glass jars+RT; T13: Pulp+MD (5%)+LDPE bags+AT; T14: Pulp+MD (5%)+LDPE bags+RT; T15: Pulp+MD (5%)+glass jars+AT; T16: Pulp+MD (5%)+glass jars+RT; MAS: Months after Storage; *: Unmarketable; NS: Non-Significant | ||||||||||||

Table 1. Effect of food additives on microbial population of avocado fruit powder.

Freeze drying reduced the total plate count of yeast and mold from 6.99 and 8.25 log CFU/mL to 5.99 and 1 log cfu/mL, in which the reduction was reported as 85.60% and 100% respectively.

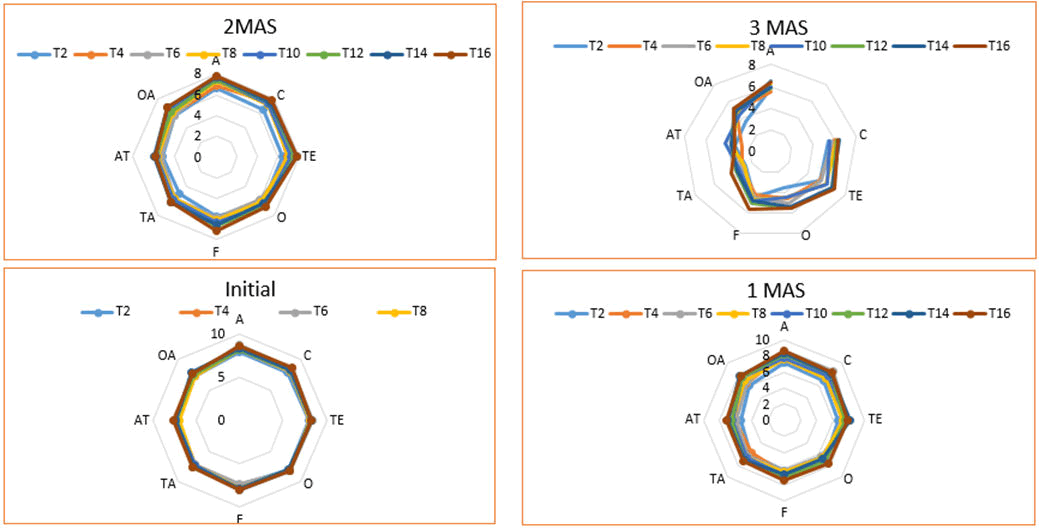

Organoleptic evaluation

Freeze dried avocado fruit powder has recorded comparatively higher organoleptic acceptance in attributes such as appearance, colour and texture than odour, flavour, taste and after taste. Higher values of Kendall's coefficient of concordance (W) for appearance, colour and texture indicated the stronger association of judgment regarding the acceptance of samples. T16 had highest total scores of 64.6, 61.9, 56 and 43.4 before storage as well as one, two and three months after storage, respectively (Figure 4).

Figure 4. Effect of food additives on biochemical qualities of avocado powder during storage.

Note: T2: Pulp+MD (2%)+LDPE bags+RT; T4: Pulp+MD (2%)+glass jars+RT; T6: Pulp+MD (3%)+LDPE bags+RT; T8: Pulp+MD (3%)+glass jars+RT; T10: Pulp+MD (4%)+LDPE bags+RT; T12: Pulp+MD (4%)+glass jars+RT; T14: Pulp+MD (5%)+LDPE bags+RT; T16: Pulp+MD (5%)+glass jars+RT; MAS: Months after Storage; *: Unmarketable; NS: Non- Significant; A: Appearance; C: Colour; TE: Texture; O: Odour; F: Flavou; TA: Taste; AT: After Taste; OA: Overall Acceptability

Owusu reported that yellowish-green colour avocado spread faded slowly in refrigerated samples than those under ambient storage with the increase in storage days [18]. It indicated the faster degradation of samples at high temperature with high oxygen availability than lower temperature. Dilrukshi and Senarath reported most acceptability for taste and texture, 75% likeness for odour, colour, appearance, and overall acceptability and low score for aftertaste and texture [19].

Cost of production

Cost of production for the 1 kg freeze dried avocado fruit powder from ripe avocado fruits of Rs.200/kg, pre-treated with food additives and packaged in LDPE laminated aluminium pouches and glass jars was observed as Rs.1224.86 (Table 2) [20].

| Avocado powder | Rate | Quantity | Cost (Rs.) |

| Avocado fruits | Rs.200/kg | 2.5 kg | 500 |

| Maltodextrin (5%) | Rs.150/500 g | 50 g | 15 |

| Ascorbic acid (1%) | Rs.300/500 g | 10 g | 6 |

| Tricalcium phosphate (0.15%) | Rs.345/500 g | 1.5 g | 1.03 |

| EDTA (0.05%) | Rs.300/500 g | 0.5 g | 0.03 |

| Potassium sorbate (0.05%) | Rs.800/500 g | 0.5 g | 0.8 |

| Freeze drying (3 kwh) | Rs.5/unit | 36 hr | 540 |

| LDPE laminated aluminium pouches | Rs.6/pack | 2 packs | 12 |

| Glass jars | Rs.10/bottle | 4 bottles | 40 |

| Labour charge | Rs.600/8 hr | 2 hr | 40 |

| Total | Rs.1224.86/kg |

Table 2. Cost of production for 1 kg freeze dried avocado fruit powder.

By reducing the drying time and minimizing the damage of the product, freeze drying became cost effective, also it reduced the handling, transportation and storage cost. In freeze drying, the high cost was attributed to high equipment cost, long drying period and high energy consumption.

Conclusion

Freeze drying is an ideal pre-treatment method for the storage of avocado powder which reduces the oxidation and loss of volatile bioactive compounds in the fruit pulp. Physical parameters such as hygroscopicity and colour value a* and b* increased while L value decreased during storage. Nutritive attributes like vitamin C, total fat and organoleptic quality decreased towards the end of storage but the effect of maltodextrin was significant in reducing the loss. Peroxide value, water activity and microbial population were increased with the end of storage which were also regulated with increased concentration of maltodextrin.

Acknowledgement

The authors are grateful to the Kerala Agricultural University and Kerala Veterinary and Animal Science University for funding and providing laboratorial and technical facilities for the research.

References

- Rybak K, Parniakov O, Samborska K, et al. Energy and quality aspects of freeze-drying preceded by traditional and novel pre-treatment methods as exemplified by red bell pepper. Sustainability. 2021;13(4):2035.

- Górny K, Idaszewska N, Sydow Z, et al. Modelling the carbon footprint of various fruit and vegetable products based on a company’s internal transport data. Sustainability. 2021;13(14):7579.

- Kapoor S, Ranote PS. Antioxidant components and physico-chemical characteristics of jamun powder supplemented pear juice. J Food Sci Technol. 2016;53:2307-16.

[Crossref] [Google Scholar] [PubMed]

- Agarwal GP, Hasija SK. Microorganisms in the laboratory. Print House India Ltd., Lucknow. 1986:155.

- García ED, Hernández JA, Vargas RD, et al. Method of obtaining avocado powder. United States Patent. 2008: US 2008/0286385 A1.

- Jaya S, Das H, Mani S. Optimization of maltodextrin and tricalcium phosphate for producing vacuum dried mango powder. Int J Food Prop. 2006;9(1):13-24.

- Illeperuma CK, Nikapitiya C. Modified atmosphere packaging of minimally processed avocado cv.‘Booth 7’. J Hortic Sci Biotechnol. 2006;81(4):607-12.

- Cenobio-Galindo AD, Ocampo-López J, Reyes-Munguía A, et al. Influence of bioactive compounds incorporated in a nanoemulsion as coating on avocado fruits (Persea americana) during postharvest storage: Antioxidant activity, physicochemical changes and structural evaluation. Antioxidants. 2019;8(10):500.

[Crossref] [Google Scholar] [PubMed]

- Mujaffar S, Dipnarine TA. The production of dried avocado (Persea americana) powder. IConETech-2020, Faculty of Engineering, The UWI, St. Augustine. 2020:44-54.

- Sagar VR, Kumar PS. Recent advances in drying and dehydration of fruits and vegetables: A review. J Food Sci Technol. 2010;47:15-26.

[Crossref] [Google Scholar] [PubMed]

- Dilrukshi SH, Senarath HP. Development and quality evaluation of freeze?dried instant green smoothie powder. Int J Food Sci. 2021;2021:6634764.

[Crossref] [Google Scholar] [PubMed]

- Yahia EM. Avocado. Crop Post?Harvest: Science and Technology: Perishables. 2012:159-86.

- Pandey S, Kumari A, Varghese KS, et al. Development of phytonutrient enriched avocado milkshake powder and its quality evaluation. Indian J Dairy Sci. 2020;73(6).

- Dantas D, Pasquali MA, Cavalcanti-Mata M, et al. Influence of spray drying conditions on the properties of avocado powder drink. Food Chem. 2018;266:284-91.

[Crossref] [Google Scholar] [PubMed]

- Castañeda-Saucedo MC, Valdés-Miramontes EH, Tapia-Campos E, et al. Effect of freeze-drying and production process on the chemical composition and fatty acids profile of avocado pulp. Rev Chil Nutr. 2014;41(4):404-11.

- Oyinloye TM, Yoon WB. Effect of freeze-drying on quality and grinding process of food produce: A review. Processes. 2020;8(3):354.

- Cortés-Rodríguez M, Orrego-Vargas FS, Rodríguez-Sandoval E. Optimization of guacamole formulation made with avocado powder and fresh avocado. Dyna. 2019;86(209):126-34.

- Owusu AA. Formulation and shelf life evaluation of avocado (Persea americana) fruit spread. Thesis, Kwame Nkrumah University of Science and Technology, Ghana. 2012.

- Ford NA, Liu AG. The forgotten fruit: A case for consuming avocado within the traditional Mediterranean diet. Front Nutr. 2020;7:78.

[Crossref] [Google Scholar] [PubMed]

- Gaidhani KA, Harwalkar M, Bhambere D, et al. Lyophilization/freeze drying–A review. World J Pharm Res. 2015;4(8):516-43.