Short Article - Journal of Food Technology and Preservation (2017) Volume 1, Issue 1

Opinion version of cheese making technology

Vincent John*Department of Food Science, Universidade de Sao Paulo, Argentina

- *Corresponding Author:

- Vincent John

Food Technology and Nutrition

Universidade de Sao Paulo

Argentina

Tel: +55 11 3091-3116

E-mail: vincentjohnvj@rediffmail.com

Accepted date: February 23, 2017

Citation: John V. Opinion version of cheese making technology. J Food Technol Pres. 2017;1:35-36

Abstract

This is regards my opinion report on cheese making technologies, Cheese is also pronounced as Cheddar. Cheese is a sustenance got from drain that is delivered in an extensive variety of flavours, surfaces, and structures by coagulation of the drain protein casein. It involves proteins and fat from drain, for the most part the drain of dairy animals, wild ox, goats, or sheep. Amid generation, the drain is typically fermented, and including the protein rennet causes coagulation. The solids are isolated and squeezed into last form. Some cheeses have shape on the skin or all through. Most cheeses liquefy at cooking temperature. Many sorts of cheese from different nations are created

Keywords

Cheese; Cheddar; Coagulation; Flavour; Paneer, Cooking

Processing of Cheese

This is regards my opinion report on cheese making technologies, Cheese is also pronounced as Cheddar. Cheese is a sustenance got from drain that is delivered in an extensive variety of flavours, surfaces, and structures by coagulation of the drain protein casein. It involves proteins and fat from drain, for the most part the drain of dairy animals, wild ox, goats, or sheep. Amid generation, the drain is typically fermented, and including the protein rennet causes coagulation. The solids are isolated and squeezed into last form. Some cheeses have shape on the skin or all through. Most cheeses liquefy at cooking temperature. Many sorts of cheese from different nations are created. Their styles, surfaces and flavour rely on upon the starting point of the drain (counting the creature's eating routine), regardless of whether they have been purified, the butterfat content, the microorganisms and form, the handling, and maturing. Herbs, flavour, or wood smoke might be utilized as seasoning operators. The yellow to red shade of many cheeses, for example, Red Leicester, is created by including annatto. Different fixings might be added to a few cheeses, for example, dark pepper, garlic, chives or cranberries. There is some debate as to the best way to store cheese, but some experts[who?] say that wrapping it in cheese paper provides optimal results. Cheese paper is coated in a porous plastic on the inside, and the outside has a layer of wax. This specific combination of plastic on the inside and wax on the outside protects the cheese by allowing condensation on the cheese to be wicked away while preventing moisture from within the cheese escaping. A specialist seller of cheese is sometimes known as a cheese monger. Becoming an expert in this field requires some formal education and years of tasting and hands-on experience, much like becoming an expert in wine or cuisine. The cheesemonger is responsible for all aspects of the cheese inventory: selecting the cheese menu, purchasing, receiving, storage, and ripening Figure 1. Curdling and curd processing is the one of the main processes in the making of cheese, know my hope will let you know about cheese stepping through cuddling and curd process. A formed stride in cheese making is isolating the drain into strong curds and fluid whey. Normally this is finished by acidifying (souring) the drain and including rennet. The fermentation can be expert straightforwardly by the expansion of a corrosive, for example, vinegar, in a couple cases (paneer, queso fresco). All the more usually starter microbes are utilized rather which change over drain sugars into lactic corrosive. Similar microbes (and the proteins they create) likewise assume a vast part in the possible kind of matured cheeses. Most cheeses are made with starter microscopic organisms from the Lactococcus, Lactobacillus, or Streptococcus families. Swiss starter societies likewise incorporate Propionibacter shermani, which produces carbon dioxide gas rises amid maturing, giving Swiss cheddar or Essential its structured cubes. Some crisp cheeses are soured just by corrosiveness, however most cheeses additionally utilize rennet. Rennet sets the cheddar into a solid and rubbery gel contrasted with the delicate curds delivered by acidic coagulation alone. It likewise permits turning sour at a lower causticity-vital in light of the fact that flavor-production microbes are repressed in high-acridity situations. When all is said in done, milder, littler, fresher cheeses are soured with a more prominent extent of corrosive to rennet than harder, bigger, longer-matured assortments.

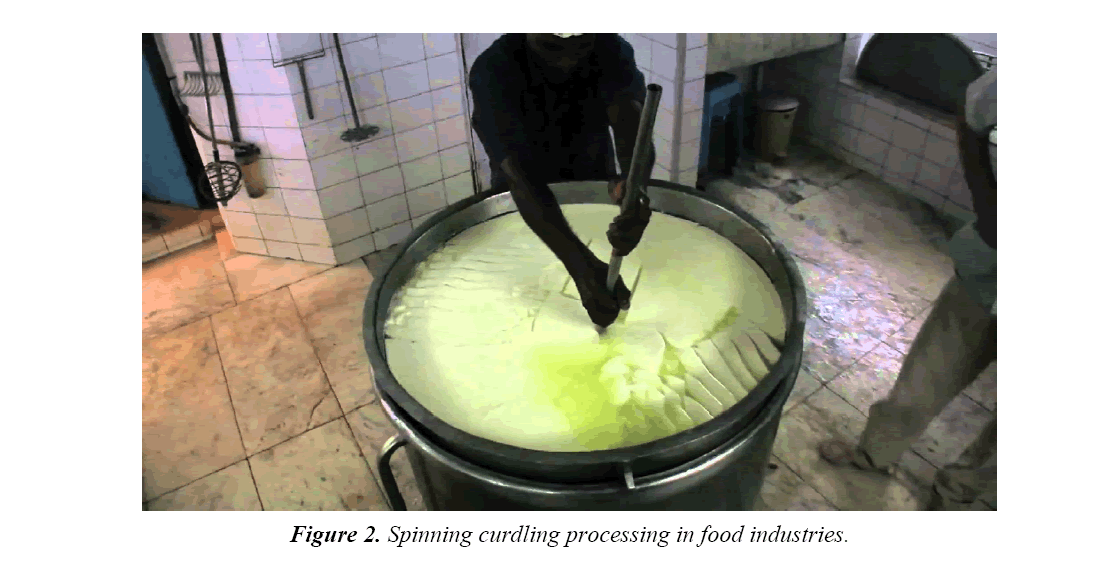

Spinning curdling processing in food industries

Processing of curd and ripening are the most successful and fine techniques used in cheese technologies, Now, the cheddar has set into an exceptionally sodden gel. Some delicate cheeses are currently basically entire: they are depleted, salted, and bundled. For the majority of the rest, the curd is cut into little 3D shapes. This permits water to deplete from the individual bits of curd. Some hard cheeses are then warmed to temperatures in the scope of 35-55°C (95-131°F). These strengths more whey from the cut curd. It additionally changes the essence of the completed cheddar, influencing both the bacterial culture and the drain science. Cheeses that are warmed to the higher temperatures are typically made with thermophile starter microscopic organisms that survive this progression-either Lactobacilli or Streptococci Figure 2. Salt has parts in cheddar other than including a salty flavour. It jelly cheddar from ruining, draws dampness from the curd, and firms cheddar's surface in a connection with its proteins. A few cheeses are salted from the outside with dry salt or saline solution washes. Most cheeses have the salt blended straightforwardly into the curds.

Demerits of cheese

Cheddar has the potential for advancing the development of Listeria microbes. Listeria mono cytogeneses can likewise bring about genuine contamination in a baby and pregnant lady and can be transmitted to her new-born child in utero or after birth. The disease has the capability of truly hurting or notwithstanding bringing on the demise of a preterm new born child, a baby of low or low birth weight, or a baby with an insusceptible framework insufficiency or an intrinsic deformity of the safe framework. The nearness of this pathogen can now and again be dictated by the indications that show up as a gastrointestinal disease in the mother. The mother can likewise obtain disease from ingesting sustenance that contains other creature items, for example, unpasteurized drain, shop meats, and sausage.