Research Article - Journal of Food Technology and Preservation (2021) Volume 5, Issue 2

Extending the shelf life of fresh pistachio by antioxidant active packaging

Ziyang He, Shikai Zhang, Laicheng Li, Fangzhou Xu, Peng Wu*

Department of Food Science, Shandong Agricultural University, Taian City, China

- Corresponding Author:

- Peng Wu

Department of Food Science, Shandong Agricultural University, Taian City, China

E-mail: 13954847828@163.com

Accepted date: 25 February, 2021

Citation: He Z, Zhang S, Li L,et al. Extending the shelf life of fresh pistachio by antioxidant active packaging. J Food Technol Pres 2021;5(2):2-7.

Abstract

In general, fresh pistachio rapidly degrades under normal conditions. In this study, we first investigated how the efficiency of antioxidant packaging systems affects the shelf life of pistachio samples. Packaging systems include antioxidant active packaging containing cinnamon essential oil, spraying stannous chloride, modified atmosphere with nitrogen packaging (MAP), as well as the combinations of the three. Since sensory quality is usually taken into account in selecting the best packaging system, a comprehensive sensory study was performed for the assessment of each option, and some parameters, such as peroxide index, microbial assessment, and aflatoxin concentration, were investigated. Results revealed that, when these parameters were considered in total, active packaging with sprayed stannous chloride was noted as an effective approach for shelf life extension. In particular, active packaging with spraying stannous chloride simultaneously preserves the high quality of sensorial properties for packaged fresh pistachio and inhibits microbial growth.

Keywords

Pistachio, Active packaging, Stannous chloride, Essential oils, Shelf life.

Introduction

Pistachio is not only one of the delicious edible nuts, but it is also known for its many health profits. Pistachios are one of the nutrients with high nutritional value. Although all edible nuts belong to the group of healthy and nutritious foods, pistachios are distinguished in particular because of their complete nutritional value and benefits to the body. Pistachio is one of the edible nuts with the highest amount of fiber and fat and is also rich in vitamins, minerals, proteins and essential fatty acids [1]. USA is the first exporter of pistachio and Iran is the second exporter of pistachio in the world, by exporting 144,300 tons in 2018 [2], and there is a fast growth in pistachio production [3]. Kernel and shelled pistachios are both marketed in large amounts. Shelled pistachios are enclosed in dehiscent hulls, i.e., soft envelopes of fleshy mesocarp and epicarp. These envelopes or hulls release a pleasant scent reminiscent of Pinus resin due to their enriched pinene content [4]. Fresh pistachio lasts short, and its nut undergoes physical and chemical structural changes after 2 days. Thus, pistachios are dried or processed for export. However, drying alters nut quality. Several studies on drying pistachio are found in literature [5-8]. Drying hazelnuts at high temperatures (more than 50°C) is not recommended since such temperatures increase the rate of rancidity reactions and degrade hazelnut quality. Meanwhile, drying temperature affects the sensory properties of pistachio and high-temperature drying intensifies the nut is roasted flavor [9]. Some scholars attempted to prolong the shelf life of fresh pistachio [10,11]. Fresh pistachio is not exported and given low research attention. Active packaging is a One solution to the above-mentioned problem used in several food products [12,13].

The term of active packaging states to innovative packaging structures helping increase shelf life, improve safety, show information on quality, and monitor freshness in foods, fruits, pharmaceuticals, and numerous product types [2]. Generally, this strategy applies chemical or natural compounds into packaging materials, planned to purposely absorb or release substances from or into the food or its surroundings. Some examples are carbon dioxide and oxygen emitters or scavengers, ethylene scavengers, ethanol emitters, flavor and odor absorbers, and moisture absorbers. Increasing the safety and shelf life of sensitive fruits by active materials is currently an interesting research area. Commercially available Table 1 summarizes the recent works on packaging materials used for pistachio shelf life extension. In this work, a novel active packaging system is designed for fresh pistachio. This system increases the product’s shelf life with minimized sensory property changes.

| Sample | Variable | Reference |

|---|---|---|

| Pistachio nut paste | Different packaging and storage conditions | (Gaml and Hayoglu, 2007) |

| Roasted pistachio | Modification of atmospheric, conditions,packaging materials and storage temperature | (Masoomeh Raei, Mortazavi, and Pourazarang, 2010) |

| Raw dried pistachio nuts | Packaging systems at different conditions | (Leufven, Sedaghat, and Habibi, 2010) |

| Pistachio kernels | Effects of wheat starch edible films | (Javanmard, Ahangari, and Tavakolipour, 2011) |

| Pistachio nuts | Changing of plastic packaging films | (Shakerardekani and Karim, 2013) |

| (Pistacia vera L.) oil | Modified atmospheric conditions and different packaging materials | (M Raei and Jafari, 2013) |

| Fresh raw pistachios | Packaging type | (Ozturk, Sagdic, Yalcin, Capar, and Asyali, 2016) |

| Fresh raw pistachios | UV-C irradiation | (Hosseini and Akhavan, 2019) |

Table 1. Recent works on the effect of packaging materials on shelf life of 530 pistachio.

Materials and Methods

Fresh Pistachio samples (Shahpasand cultivar) were obtained from pistachio orchards of Mehmandost Damghan (Semnan, Iran). Tin (II) chloride dehydrate were prepared from Merck, Germany. A 200 mg mL-1 solution of SnCl2 in ethanol was prepared and applied on fresh pistachio by spray bottle (approximately 1 mL for 100 g of fresh pistachio). Tin standards for ICP analysis were prepared by dilution of a 1000 mg/L tin stock solution (Merck). Samples (200 g) were packaged in sealed one side aluminum one side transparent stand up zipper bags (26 cm × 20 cm). It is a barrier against oxygen, water vapor, dust, bacteria, etc.

Active paraffin formulation containing 1 mg/g amount of the essential oil was prepared through mixing cinnamon essential oil and solid paraffin and heating at around 110? for 5 min in a closed vessel. Active paraffin (100 mg/cm2) was then manually coated on 5 cm2 the surface of one side of the bag(Masqué, Marcé, Borrull, Cormack, and Sherrington, 2000). In addition, 0.5 g of silica gel packet (Wisepac Active Packaging Components) was put inside the packages to control condensation. Modified atmosphere by N2 (100%) was used for evaluating the effect of atmospheres. To prevent of penetration of N2, a manual sealing machine was used for packaging in modified atmosphere groups in addition to zipping of bags.

Ninety packaged samples were used in this investigation. The tilts of packaging groups were examined as follows:

• Simple packaging, without any additive (control group)

• Active packaging group (0.5 mg EO)

• Active packaging group (0.5 mg EO), sprayed samples with stannous chloride

• Modified atmosphere packaging group, (non-active)

• Active packaging+modified atmosphere (0.5 mg EO)

• Active packaging+modified atmosphere (0.5 mg EO) in label, sprayed samples with stannous chloride

For each group, 15 replicates were obtained and stored at 4°C in a refrigerator. Microbiological assessments were performed after 7, 15, 30, 45, 60, 75, and 90 days since the pistachios were packaged. For sensory analysis, a trained panel of seven individual members was recruited to evaluate the effect of packaging on the shelf life and quality of the pistachio samples. Responses given by panelists were comprised and classified in a scale in which several descriptors were defined based on their relevance in the final quality. The sense of the panelists about quality of pistachio packaged samples (flavor, taste, texture, and color) and the level of the differences were evaluated in a scale ranging from 1 to 5 points, with 5 as the highest quality. Pistachio (one for each packaging group) was served on odorless white glass plates and coded with random numbers.

Determination of peroxide and Iodine value

Oxidation of fat substances produce peroxide leading to undesirable aroma and flavor; thus, it is an indicator for fat oxidation. We analyzed it at the beginning of storage time (instantly after packaging) and weekly until the end of storage (after three months of storage). Production of peroxide gently increased in the initial days. However, in the next stages, it acts as a catalyzer in oil oxidation. More than 89% of pistachio fatty acids are unsaturated. Peroxide measurement was performed according to the Shantha and Decker method [11]. The quantity of absorbed iodine for a 100 g oil sample indicates the iodine index. This index is calculated as a criterion for the degree of unsaturation in unsaturated fatty acids, such as oleic acid. In this study, the iodine value was determined in accordance with the AOAC standard [14]. Assays were carried out at similar times for peroxide value determination.

Preparation of Aspergillus flavus and parasiticus agar (AFPA) culture for microbial assessment

AFPA culture was used for assessing the microbial aspect, this specific culture medium provides growth conditions for A. flavus and A. parasitocus, and it is a possible characterization of a kind of toxic factor. This culture medium was employed for the differential detection of A. flavus and A. parasiticus groups through the production of typically yellow to olive-green conidia and a bright-orange reverse coloration. Aspergillus flavus parasiticus agar (AFPA) was prepared by dissolving 4 g of yeast extract, 2 g of bacteriological peptone, 0.1 g of ferric ammonium citrate, 0.2 ml of Dichloran 0.2% in ethanol, 0.02 g of chloramphenicol, and 3 g of agar in 200 ml of distilled water, final pH 6.0-6.5. To prepare each sample, 10 g of pistachio with hull were grounded and added to 90 mL of peptone water 1%. This mixture was shaken and diluted to final concentrations of 1:10 and 1:100. The Petri dishes were maintained at 28°C for 3 days to 7 days after inoculation. The A. flavus colonies were counted and isolated. The rates of A. flavus contamination in different pistachio samples were compared with each other. In the next phase, the capacity to produce aflatoxins by 86 isolates of A. flavus was determined [15]. To assess of toxins production from fungi in packaged pistachio samples, cultivation of fungi on PDA medium was organized. The specimens were placed in an incubator at 28°C for 3-5 days. The cultured colonies of each fungus were separately purified, and the pure colonies grown on PDA were studied by the naked eye and through microscope.

Determination of aflatoxins in pistachio samples

The aflatoxin levels in the pistachio samples were analyzed based on an immunoaffinity column/HPLC [16]. The HPLC instrument (Knauer D-14163; Berlin, Germany) was used. Other details; Dare D-14163 pump, a reversed C18 column (4.6 mm × 150 mm), and a reversed C18 guard column (4.6 mm × 15 mm) coupled with a fluorescence detector (RF-10A XL, Shimadzu) at 365 nm (excitation) and 435 nm (emission). A post-column photochemical derivatization acquired from LC Tech, Germany (UVE UV Derivatization Module for the Analysis of Aflatoxins) was used to enhance detection. Derivatization is required prior to analysis of B1 and G1 aflatoxins. It was performed by irradiation with UV light at 254 nm with the photochemical reactor (UVE; LC Tech, Germany).

For sample preparation, the sample (kernel and hull) was grounded and homogenized, and aflatoxins were then extracted from 10 g of homogenized sample through shaking with 40 mL of methanol/water (8:2, v/v), sodium chloride (1 g), and hexane (20 mL) for 3 min. Subsequently, hexane phase was removed and sample was filtered, and it was diluted (1:4) with phosphate-buffered saline. In the next step, the sample was purified by an immune-affinity column. Finally, purified sample (20 µL) was injected into the HPLC column at a flow rate of 1.0 mL min-1 isocratically w. With the mobile phase of water/acetonitrile/methanol (60:15:30) [17].

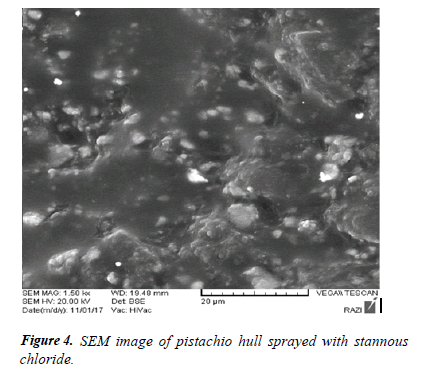

Surface morphology: 200 A Scanning Electron Microscopy (SEM) system (model VEGA, TESCAN, Brno, Czech Republic) was employed for investigation of distribution of stannous chloride on the samples sprayed on the surface of pistachio hull. This scanning electronic microscope was equipped with a field-emission gun.

Determination of tin in pistachio samples

Tin content pistachio samples in the control and other groups were analyzed. The inductively coupled plasma atomic emission spectrometer ICPOES equipment (Integra XL, GBC, Australia) was used for the determination of tin. Operating conditions are Power, 1300 W; Plasma gas-flow, 18 L min-1 ; Aux. flow, 2.25 L min-1; Emission lines (nm); 189.927, 283.998, 235.485, Internal standard, In 303.936 (40 mg/L) and Sr 338.071 (10 mg/L) [18].

Statistical analysis: SPSS version 22 (SPSS, Inc., USA) was used for statistical analysis through one-way ANOVA, and Tukey’s HSD as post hoc test. Values of P<0.05 were considered significant.

Results and Discussion

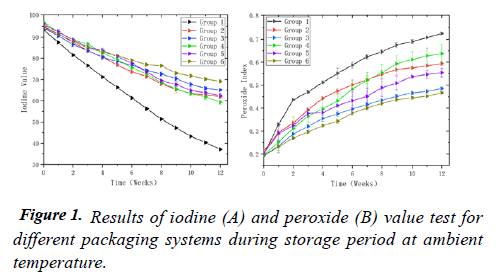

Iodine and peroxide values

The obtained results for iodine value in the pistachio samples indicated a significant variance in iodine value among control and other intervention groups. Iodine value in all groups decreased by time. As can be seen in Figure 1, during 12 weeks of storage, packaged pistachio in control group had the highest loss in iodine value while other groups had lower loss in iodine value (p<0.05). However, a significant difference was not observed among different packaging systems in iodine value during storage times (p<0.05). Reduction amount of unsaturated fatty acids in oil and subsequently destruction of double bands causing from oxidation, isomerization, and polymerization lead to decrease decreased of iodine value during storage periods [19-23] and subsequently destruction of double bands causing from oxidation, isomerization, and polymerization lead to decrease of iodine value during storage periods [24]. In this research, packaging that is oxygen barrier is used and pistachio packages are away from direct sunlight. Rate of rancidity and browning reactions resulted from lipid oxidation in kernel of pistachio reduced in the pistachio samples that were actively packaged. As observed in Figure 1, after 12 weeks of storage, a significant difference in peroxide value was observed between control and other groups. The highest peroxide value was related to control. It can be explained that active packaging acts as a barrier agent and inhibits oxidation. Modified atmosphere improves this condition; however, there is not a significant difference in other packaging systems.

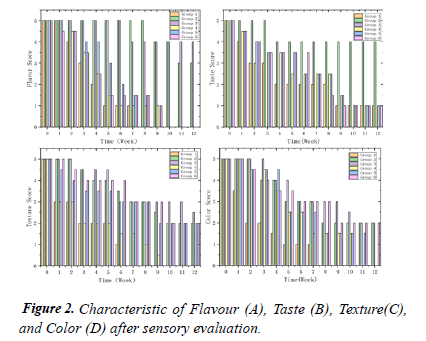

Sensory test: Affected by the chemical degradation of bioactive compounds, sensory characteristics of fresh pistachio samples comprise an important factor in studying packaged pistachio and On the contrary, Cinnamon EO and other parameters can may affect the characteristics, like flavor, texture, and taste, in turn influencing the final product. Apart from the health effects and aflatoxin growth in packaged samples, sensory properties are essential in nuts. Thus, the sensory properties of packaged pistachio were examined weekly by an expert panel [25].

Flavour: As indicated by the results of the flavor test performed by an expert panelist (Figure 2), active packaging significantly affects the flavor of the packaged samples, The presence of stannous chloride improved the quality of the packaged sample, whereas modified atmosphere with N2 had no significant effect on flavor. The quality and flavor of the fresh pistachio rapidly decreased in the control group, whereas those of the modified atmosphere with N2 group were not positively affected.

Taste: The taste of the packaged traditional samples changed, and the quality of the samples decreased. As shown in Figure 2, the taste of the pistachio samples in the active packaging group improved significantly. This effect may be due to the antioxidant properties of essential oil as well as the ability of stannous chloride to maintain the quality of fresh pistachio.

Texture: In pistachio samples, texture is highly important. The obtained results were like those of the other parameters of active packaging, and stannous chloride can fix the texture quality constant after 4 weeks. Subsequently, a low decrease in quality occurred. In the modified atmosphere groups, rapid decrease in this parameter was observed. Figure 2 reveals the results obtained for this parameter.

Color: The color of the outer shell changes very rapidly in fresh pistachio. This change in color can affect customer satisfaction; hence, it was evaluated in different groups. Like the other parameters, the color of the pistachio hull can be stabilized by active packaging, and particularly, stannous chloride may improve this stability. Figure 2 shows the results obtained for this parameter.

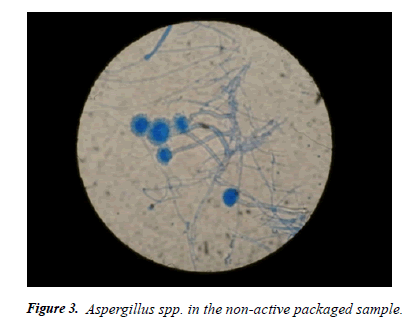

Microbiological assessment: Microbiological results show that in the control group, Aspergillus spp. was seen in the specific culture medium of AFPA, the fungus colonies were observed macroscopically and microscopically. No Aspergillus colony was detected in pistachio samples kept in active packaging [26].

The presence of A. flavus was confirmed by the corresponding images. The production of A. flavus and A. parasiticus can be impeded by active packaging, an image of Aspergillus spp. in a non-active packaged sample is exhibited in Figure 3.

Aflatoxin determination in different groups

AFs were not found in the active packaging groups. In traditional packaging, some samples were detected as contaminated with aflatoxins. All contaminated samples contained AFB1. The overall mean contamination levels were 2.3 ± 5.2 ng/g for AFs and 3.1 ± 4.0 ng/g for AFB1. The average concentrations become only 2.3 ± 3.0 ng/g or AFs and 5.1 ± 6.6 ng/g for AFB1.

SEM studies: SEM images present a pistachio hull surface with a uniform distribution of nanoparticles. The dispersed nanoparticles were approximately 80 nm in size (Figure 4). Some agglomeration occurs after drying the synthesized nanocomposite.

Tin contents: The result for tin content in pistachio samples show that its concentration varied from 1.4 to 2.6 mg/100 g dry weight. Nevertheless, there is not a statistical difference in tin content in different groups (p<0.05). This result confirmed that the sprayed tin could not penetrate from outer shell of pistachio inside the nut and the analyzed tin content is appropriate for natural tin content in pistachio [27-29].

Conclusion

The results of this study confirm that applying active packaging to fresh pistachio can extend the nut’s shelf life, and important parameters, such as flavor, taste, and texture, are not altered. Moreover, from a health perspective, active packaging prevents microbial growth and aflatoxin accumulation in pistachio. Stannous chloride may improve the shelf life of the designed active packaging. However, a modified atmosphere holds no positive effect on the shelf life. Sensory properties, like flavor, texture, and taste, were better without MAP; thus, N2 did not positively affect the shelf life of the pistachio samples.

Since the production of fungal toxins occurs under certain conditions and the increased presence of fungi cannot be attributed to its toxicity, the presence of aflatoxins B1, B2, G1, and G2 in samples were investigated. Active packaging may prevents the production of aflatoxin in packaged pistachio and it is of great importance for the health aspect. Furthermore, the packaging system affords the potential to export fresh pistachio to other countries for the first time.

References

- Janick J, Paull RE. The encyclopedia of fruit and nuts CABI. 2008.

- Joya JAA, Zapata MADL, Alvarez-Perez OB, et al. Basic and applied concepts of edible packaging for foods. J Food Process Preserv. 2018;12:1-61.

- Kashaninejad M, Mortazavi A, Safekordi A, et al. Some physical properties of Pistachio (Pistacia vera L.) nut and its kernel. J Food Eng. 2006;72(1):30-38.

- Chahed T, Dhifi W, Hosni K, et al. Composition of Tunisian pistachio hull essential oil during fruit formation and ripening. J Essent Oil Res. 2008;20(2):122-125.

- Ghazanfari A, Tabil Jr L, Sokhansanj S. Evaluating a solar dryer for in-shell drying of split pistachio nuts. Dry Techn. 2003;21(7):1357-1368.

- Kashani Nejad M, Tabil L, Mortazavi A, et al. Effect of drying methods on quality of pistachio nuts. Dry Tech. 2003;21(5):821-838.

- Kashaninejad M, Mortazavi A, Safekordi A, et al. Thin-layer drying characteristics and modeling of pistachio nuts. J Food Eng. 2007;78(1):98-108.

- Omid M, Baharlooei A, Ahmadi H. Modeling drying kinetics of pistachio nuts with multilayer feed-forward neural network. Dry Tech. 2009; 27(10):1069-1077.

- Pycia K, Kapusta I, Jaworska G, et al. Type of heat treatments on walnut fruits affects physicochemical content of walnut butter. 2019;43(5):e13923.

- Mousavi FP, Pour HH, Nasab AH, et al. Investigation into shelf life of fresh dates and pistachios in a package modified with nano-silver. Glob J Health Sci. 2016;8(5):134-144.

- Shantha NC, Decker EA. Rapid, sensitive, iron-based spectrophotometric methods for determination of peroxide values of food lipids. J AOAC Int. 1994;77(2):421-424.

- Dainelli D, Gontard N, Spyropoulos D et al. Active and intelligent food packaging: legal aspects and safety concerns. Trends Food Sci Technol. 2008; 19(1):S103-S112.

- Quintavalla S, Vicini L. Antimicrobial food packaging in meat industry. Meat Sci. 2002;62(3):373-380.

- Akinhanmi T, Atasie V, Akintokun P. Chemical composition and physicochemical properties of cashew nut (Anacardium occidentale) oil and cashew nut shell liquid. JAES. 2008;2(1):1-10.

- Leontopoulos D, Siafaka A, Markaki P. Black olives as substrate for Aspergillus parasiticus growth and aflatoxin B1 production. Food Microbio. 2003;20(1):119-126.

- Ghali R, Khlifa KH, Ghorbel H, et al. Aflatoxin determination in commonly consumed foods in TunisiaJ. Food Sci. 2010; 90(14):2347-2351.

- Kilicel,Kilicel F, Karapinar H S, Cimen A. Quantitation of aflatoxins in food materials using HPLC-FLD method. Anal Chem. 2017;5(6):90-97.

- Kilicel F, Karapinar H S, Cimen A. Quantitation of aflatoxins in food materials using HPLC-FLD method. Anal Chem. 2017;5(6):90-97.

- Perri Perring ng L,Basic Dvorzak M. Determination of total tin in canned food using inductively coupled plasma atomic emission spectroscopy. Anal Bioanal Chem. 2002;374(2):235-243.

- Ghali,Gaml Ö F, Hayoglu I. The effect of the different packaging and storage conditions on the quality of pistachio nut paste. J Food Eng. 2007; 78(2): 443-448.

- Siddique Siddique BM, Muhamad II, Ahmad A, et al. Effect of frying on the rheological and chemical properties of palm oil and its blends. J Food Sci Technol. 2015;52(3):1444-1452.

- Gaml Ö F, Hayoglu I. The effect of the different packaging and storage conditions on the quality of pistachio nut paste. J Food Eng. 2007; 78(2): 443-448.

- Hosseini FS, Akhavan H R. Effects of a rotational UV-C irradiation system and packaging on the shelf life of fresh pistachio. J Sci Food Agric. 2019;99(11):5229-5238.

- Javanmard M, Ahangari R, Tavakolipour H. Effects of wheat starch edible films on rancidity and moisture uptake of pistachio kernels as a new package. J Food Process Eng. 2011; 34(4):1156-1171.

- Leufven A, Sedaghat N, Habibi M. Influence of different packaging systems on stability of raw dried pistachio nuts at various conditions. AEJAES. 2010;8(5):576-581.

- Masqué N, Marcé RM, Borrull F, et al. Synthesis and evaluation of a molecularly imprinted polymer for selective on-line solid-phase extraction of 4-nitrophenol from environmental water. Anal Chem. 2000; 72(17):4122-4126.

- Ozturk I, Sagdic O, Yalcin H, et al. The effects of packaging type on the quality characteristics of fresh raw pistachios (Pistacia vera L.) during the storage. Lwt-Food Sci Technol. 2016;65:457-463.

- Raei M, Jafari S. Influence of modified atmospheric conditions and different packaging materials on pistachio (Pistacia vera L.) oil quality. Lat Am Appl Res.2013;43(1):43-46.

- Raei M, Mortazavi A, Pourazarang H. Effects of packaging materials, modified atmospheric conditions, and storage temperature on physicochemical properties of roasted pistachio nut. Food Anal. Methods. 2010;3(2):129-132.