Research Article - Journal of Food Technology and Preservation (2017) Volume 1, Issue 1

Experimental validation on effects of pulsed electric field treatment on the sensory quality of vegetable juices

Soumitra Banerjee*

Food Science, Jyothy Institute of Bangalore, Karnataka, India.

- *Corresponding Author:

- Abinaya V1*, Soumitra Banerjee2, Madhu Palati3

Food Science

1Department of Food Technology, Jain University Bangalore, Karnataka ? 562112, INDIA

- 2Center for Incubation, Innovation, Research & Consultancy (CIIRC), Jyothy Institute of Technology, Bangalore,Karnataka - 560082, INDIA

- 3Department of Electrical & Electronics Engineering, BMS Institute of Technology & Management, Bangalore, Karnataka - 560064, INDIA

Tel: + 095354 23635

E-mail: soumitra.banerjee7@gmail.com

Accepted date: April 24, 2017

Citation: Banerjee S. Experimental validation on effects of pulsed electric field treatment on the sensory quality of vegetable juices. J Food Technol Pres. 2017;1:56-60

Abstract

Pulsed electric field (PEF) treatment is one of the non-thermal methods of food processing. PEF technology has been reported and recognized by a number of food researchers as an alternate method of conventional thermal processing for fluid and semi-fluid foods. Recently, the PEF technique application has been exploited in the field of extraction of bio-molecules, drying enhancement and enzyme activity modification. PEF has also proved significant and more effective application with moderate thermal treatment for food preservation as hurdle technology. Although significant work was found in the domain of milk and fruit juice processing and preservation, but limited reported work was found in the area of application of PEF for vegetable juice processing while no reported work was found on PEF treatment of mint and curry leaves juices. This paper reports about application of PEF and its effects in sensory qualities of the vegetable juices after a specified treatment. Few vegetable juices were treated, i.e. cabbage, cucumber, bitter gourd along with mint leaves and curry leaves. No changes in sensory properties were found between treated and untreated samples.

Keywords

Pulsed electric field, Vegetable juice processing, Sensory effects.

Introduction

Over past few decades, a number of preservation methods have been introduced in food processing which involves inactivating the microorganisms present in the food, at lower temperature instead of conventional high temperature heat treatments. This process of extending shelf life of the food without any significant heat treatment is known as “Non-Thermal Processing” [1]. Among all the emerging non-thermal preservation method, high intensity Pulse Electric Field (PEF) is an efficient one. It is designed to deactivate the microorganisms without significant rise in temperature. Pulse electric field preservation method have potential to enhance the shelf life by inactivating the microorganism present in the food without much changes in sensory and nutritional qualities of food [2]. This technique involves in the use of short pulses of electricity that passed through the liquid or semi-solid food sample. PEF treatments involves in the microbial inactivation mainly in milk, dairy products, whole eggs, juices and other kinds of liquid foods [3]. History of PEF treatment could be traced back in 1900s, when electricity was perhaps first time utilized for milk pasteurization, in a technique called as Electro pure method [4]. Flaumenbaum [5] used the electric field on fruits to increase its permeability and extract the juice from it. Gilliland and Speck [6] introduced the Electro-hydrolytic method to destroy the microorganisms present in liquid system, by using shock waves generated by an electric arc. In 1987, Dunn and Pearlman [7] applied electric field on fruit juices as the result it showed increase in shelf life. Till 1980, pulse electric field was known as one of the preservation technique that were used but later on Chang et al. [8] was considered as a novel method in “Non- Thermal Preservation” method [9-11]. In 1994, Kalchayanand et al. [12] stated that the adding of antimicrobials along with PEF treatment showed more inactivation of microorganism. Qin and others stated that the PEF effectively inactivating the yeast, vegetative bacteria and moulds. In 1996, FDA had given the approval to treat the liquid eggs using pulse electric field method. Bacteria like Lactobacillus brevis was introduced into citrus juice and PEF treatment on the juice were experimentally carried out by Elez-Martinez and others [2,13-15].

PEF-Principle and Mechanism

Pulse electric field is an efficient non-thermal preservation technique that increases the shelf life of the liquid food by inactivating the microorganisms and enhances the shelf life of food product without significantly affecting the nutritional content of the food [2]. The main principle involved in PEF technology is applying short pulses of high electric field to the liquid food that breaks the cell membrane of microorganism, by creating the pores on the cell. Electric field intensity, pulse duration and number of pulses are the factors that responsible for reversible or irreversible pore formation [10,16,17]. Two mechanism are involved in the PEF action on cell membrane of the microorganism i.e. Electroporation and Electrical breakdown. Electroporation causes increase in the membrane permeability resulting in the breakdown of cell wall and leaking out of cytoplasm, resulting in cell death explained by Chang. Osmotic imbalance theory is involved that include electroporation and electrical break down in cell. The cell exposed to an external electric field is electroporated through the leakage of ion and small molecule and thus membrane became permeable to water that causes swelling, rupture and finally cell lysis occurs [10,18-20].

Application of PEF Technology in Juice Processing

It involves in improving the shelf life of food products like milk, fruits juices, liquid eggs, fermentation properties of brewer’s yeast. By using PEF technique the shelf lives of the juice have been extended and also shows increase in yield. In recently, antimicrobial compounds have been used along with the PEF treatment. It shows that, there is significant reduction in microbial count. PEF treated (50 kV/cm, 45°C, 10 pulses) apple juice showed increase in shelf life of about 28 days than untreated one about 21 days (Simpson et al., 1995). In orange juice, the addition of nisin (100 U/ml) along with PEF treatment (EF of 80 kV/cm, 44°C, 20 pulses with pH 3.5) showed significant reduction in microbial count of about 6.83 log cycle, before (without the addition of nisin) there was only 1.26 log cycle reduction. As the result, it extended their shelf life of the juice and also decreases PME (pectin methyl esterase) activity without any changes in nutritional properties [21]. In white grape juice the maximum reduction in count was achieved (4.4 log/ml) when 20 pulses, 65 kV/ cm, 50°C were applied along with addition lysozyme and nisin together (mixture 23.75%, 0.4 g/ml) [10]. By applying PEF in sugarcane juice, it showed increase in yield and also increases the shelf life. Sugar cane Juice undergone PEF (30 kV/cm and 150 pulses) treatment, it was found that the treated sample were more stable than untreated one stored upto 30 days. Lemon and ginger solution was added along with the sugar cane juice showed much reduction in microbes and there is no change in their sensory properties [22]. Apple juice were treated by PEF (50 μs, 10 pulses, pulse width 2 μs. and temperature of about 45°C) results increased in shelf life of juice from 21 to 28 days and there was no change in ascorbic acid or sugar content that present in the apple juice [23]. In Apple cider Vitamin C (0.1 mg/ml) were added which undergoes PEF treatment (87 kV/cm, 40 instant reversal pulses and temperature 50°C) as the result it showed that there was no loss in added vitamin C [10,11]. From the reviewed literatures, conclusion was drawn that various parameters affecting the microbial inactivation by PEF are type of microorganism, pulse wave shape, field intensity, conductivity of the medium, pH, temperature, treatment time, energy input etc. It was further concluded that pulse electric field technique involves in increasing the shelf life and maintaining food quality with low processing cost. Research gap was found on the application of PEF treatment for Indian (tropical) vegetables like cabbage, bitter gourd and cucumber. Beside this no reported literature was found on sensory effects of PEF treatment on curry leaves and mint leaves juices. Objective of this study was to find the effects on sensory properties on vegetable juices, i.e. cabbage, bitter gourd and cucumber along with two types of leaves, i.e. mint and curry leaves. These selected vegetables and leaves, have much importance in Indian society and their juices are known for various nutritional and therapeutic properties in India and abroad. Successful implementation of non-thermal processing and preservation of juices of these selected vegetables and leaves may open a new sector of processing, trade and export in food sector.

Materials and Methods

Raw vegetable and leaf samples used in this experiment, i.e. cabbage (Brassica oleracea), bitter gourd (Momordica charantia), cucumber (Cucumis sativus), mint leaves (Mentha arvensis) and curries leaves (Murraya koenigii), were procured from local markets of Bangalore-Karnataka (India). The vegetables were chopped and put in electrically operated juice extractor for extracting juice from the chopped vegetable samples. For leafy samples like mint and curry leaves, 50 ml of water was added with 50 g of sample, then grinded to get the semi-solid slurry, which was filtered to get the juice. After recovering the vegetable juice, the juice was further filtered using the muslin cloth to remove the undesirable particles from the juice. PEF treatment was done in the PEF chamber which is described in detailed below. Distilled water was used for the entire study.

PEF Setup Description

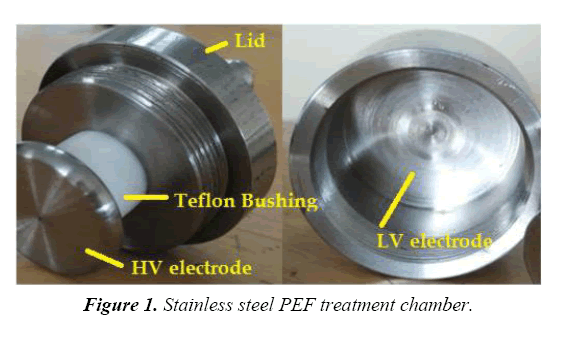

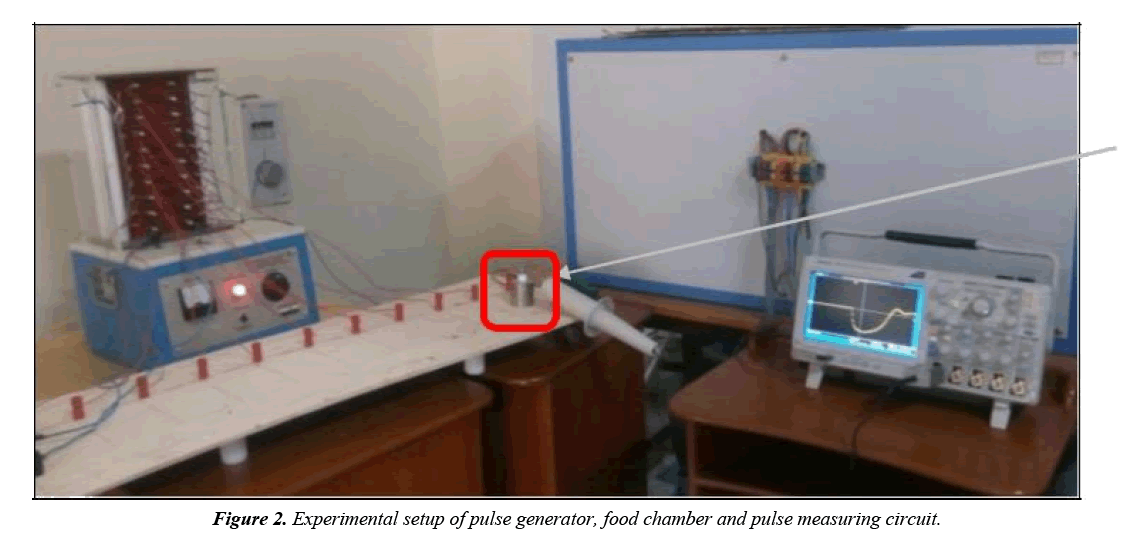

PEF set up was successfully designed, fabricated and tested for milk sample, which was used for the study [24]. The developed set up was shown in Figures 1 and 2. In the present work, generation of rectangular pulse of duration 1.8 μs was achieved by a ten stage pulse forming network (PFN) of type-B. Each stage inductor and capacitor is of rating 1 μH and 10 nF, 20 kV respectively. The PFN circuit characteristic impedance is 10 ohms. A variable DC voltage of 0-20 kV is obtained by a DC source. Output switch (spark gap) is connected at the output of PFN. The gap distance between the spark gap is adjusted to get the required voltage across the load. The food treatment chamber is a cup type stainless steel (Food Grade SS 304) chamber, acts as low voltage (LV) electrode and stainless steel lid with a hole at centre. High voltage electrode surrounded by food grade Teflon is inserted into the hole of lid and is shown in Figure 1. The Chamber is filled with liquid juice. This type of configuration gives uniform electric field in the liquid food. The experimental set up is shown in Figure 2. The food chamber is filled with 20 ml of liquid juice. All the stage capacitors are charged to 13 kV, the spark gap break down occurs and a high voltage rectangular pulse appears across the food chamber. Total 100 pulses are applied for treatment of vegetable juice. The rectangular high voltage pulse is captured by Tektronix High voltage probe model number P6015 and current pulse by a Pearson current monitor model number 101.

Treatment with pulse electric field

The juices that are extracted from raw samples were given PEF treatment which is shown in Figure 2. A sample of about 20 ml was introduced into the PEF treatment chamber in which it get contact with the electrodes and the treatment chamber were connected to the pulse forming network circuit and closed it properly in order to prevent from electric shock. Treatment of 100 pulses was given of pulse duration of 1.8 μs to the juice sample. Voltage was found to vary from 6.5 kV (matching load) which was monitored using Digital Oscilloscope (DPO 3034). The whole PEF setup was powered with 230 volts. After this process the PEF treated samples were compared with untreated juice samples and the results were reported in “Results and Discussion” section.

Results and Discussion

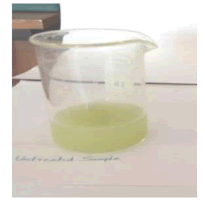

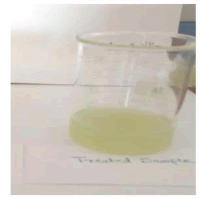

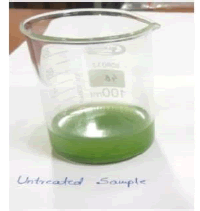

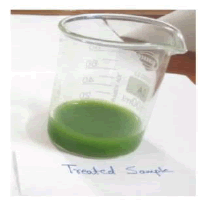

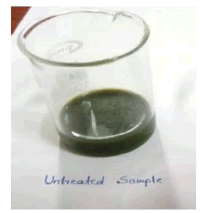

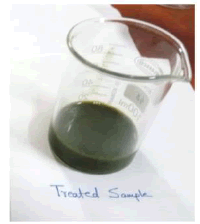

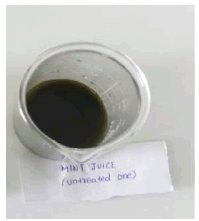

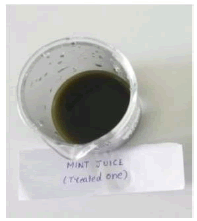

Extracted juices were treated with pulsed electric field and compared with untreated juice samples, as shown in Table 1. From the above results, it can be concluded that the juice samples (cabbage, cucumber, bitter gourd, mint leaves and curry leaves) that were treated with pulse electric field showed that there was no change in their sensory properties like colour and aroma of the treated samples. Thus the PEF technology can be applied to the liquid samples as because even after treatment the sensory properties of samples remain same. There was no change in temperature of the sample before and after treatment. Further studies may be conducted to check the effects of PEF treatment on antioxidants, micro as well as macro nutrient composition and effect of the treatment on the shelf life of the juices. The results are in agreement with other studies done on the application of PEF treatment for fruit juices and milks, where no significant changes in sensory attributes were reported, as compared to un-treated samples [25-27].

Table 1. PEF treated and un-treated juice samples.

| ype of juice sample | Un-treated sample | PEF treated sample | Results | |

|---|---|---|---|---|

| Cabbage juice |  |

|

No change in colour and aroma | |

| Cucumber juice |  |

|

No change in colour and aroma | |

| Bitter gourd juice |  |

|

No change in colour and aroma | |

| Curry leaves juice |  |

|

No change in colour and aroma | |

| Mint juice |  |

|

No change in colour and aroma | |

Conclusion

PEF is the most efficient non-thermal preservation technique used to preserve food. It has been found that there is maximum microbial reduction occurs after the sample treated with PEF technique and there has been no change in sensory and nutritional properties of the samples. Food samples like fruit juices, milk, eggs, sugarcane juice has been treated so far. Limited studies were found in the field of vegetable and leafy juice processing effects by PEF treatment. 100 pulses of 1.8 s were applied and after the treatment, the sensory qualities of treated and un-treated raw juices were compared. No changes in colour and flavour were observed from the study. Future work may be done in future to estimate the effects of treatment on nutritional qualities, antioxidants, shelf life of the juices before and after treatment.

Acknowledgements

All the authors are thankful to Director, School of Engineering and Technology, Jain University Bangalore (Karnataka, INDIA) for providing financial assistance, necessary research facilities and infra-structure to complete the work. Also the authors are thankful to Director, CIIRC-Jyothy Institute of Technology (Bangalore) and Management of BMS Institute of Technology (Bangalore) for their support successful completion of this work.

References

- Vega-Mercado H, Pothakamury UR, Chang FJ, et al. Inactivation of Escherichia coli by combining pH ionic strength and pulsed electric fields hurdles, Food Res Int. 1996:29:117-121.

- Kumar Y, Patel KK, Kumar V. Pulsed electric field processing in food technology, Int J Eng Stud Tech Approach. 2015:1:6-17.

- Qin B, Zhang Q, Barbosa-Canovas GV et al. Pulsed electric field treatment chamber design for liquid food pasteurization using a finite element method Trans ASAE. 1995:38:557-565.

- Anderson Arthur K and Rubin Finkelstein (1919) A study of the electro-pure process of treating milk J Dairy Sci. 1919:2:374-406.

- Flaumenbaum B. Electrical treatment of fruits and vegetables before juice extraction Trudy OTIKP. 1949: 3:15-20.

- Gilliland SE, Speck ML. Inactivation of microorganisms by electrohydraulic shock Appl Microbiol. 1967: 15:1031-1037.

- Dunn JE, Pearlman JS. Methods and apparatus for extending the shelf life of fluid food products US Patent. 1987: 22.

- Chang DC, Saunders JA, Chassy BM, et al. Overview of electroporation and electrofusion Guide to electroporation and electro fusion. 1992:1-6.

- Mertens B, Knorr D. Development of non-thermal processes for food preservation Food Technol. 1992:46 :123-134.

- Jayaram S, Castle GSP, Margaritis A. Kinetics of sterilization of Lactobacillus brevis cells by the application of high voltage pulses Biotechnol Bioeng. 1992:40:1412-1420.

- Grahl T, Sitzmann W, Märkl H. Killing of microorganisms in fluid media by high-voltage pulses In DECHEMA Biotechnology Conferences. 1992:675-677.

- Kalchayanand N, Sikes T, Dunne C et al. Hydrostatic pressure and electroporation have increased bactericidal efficiency in combination with bacteriocins. Appl Environ Microbiol. 1994:60:4174-4177.

- 13 Elez-Martinez P, Escolà-Hernández J, Soliva-Fortuny RC, et al. Inactivation of Lactobacillus brevis in orange juice by high-intensity pulsed electric fields Food Microbiol. 2005: 22:311-319.

- Sun DW. Emerging technologies for food processing Elsevier, 2014.

- Liang Z, Mittal GS, Griffiths MW. Inactivation of Salmonella Typhimurium in orange juice containing antimicrobial agents by pulsed electric field, J Food Prot. 2002:65:1081-1087.

- Zhang Q, Qin BL, Barbosa-Cánovas GV, et al. Inactivation of E coli for food pasteurization by high-strength pulsed electric fields. J Food Process Preserv. 1995:19:103-118.

- Qin BL, Pothakamury UR, Barbosa-Cánovas GV, et al. Nonthermal pasteurization of liquid foods using high-intensity pulsed electric fields, Crit Rev Food Sci Nutr. 1996:36:603-627.

- Min S, Zhang QH. Effects of Commercial-scale Pulsed Electric Field Processing on Flavor and Color of Tomato, Juice Journal of Food Science. 2003:68:1600-1606.

- Jeyamkondan S, Jayas DS, Holley RA. Pulsed electric field processing of foods: a review Journal of Food Protection. 1999:62:1088-1096.

- Buckow R and Toepfl S, et al. Pulsed electric field processing of orange juice: a review on microbial enzymatic nutritional and sensory quality and stability, Compr Rev Food Sci Food Saf. 2013:12:455-467.

- Hodgins AM, Mittal GS, Griffiths MW. Pasteurization of Fresh Orange Juice Using Low-Energy Pulsed Electrical Field J Food Sci. 2002:67:2294-2299.

- Kayalvizhi V, Pushpa AJS, Sangeetha G et al. Effect of pulsed electric field (PEF) treatment on sugarcane juice, Journal of Food Science and Technology. 2016:53:1371-1379.

- Simpson MV, Barbosa-Cánovas GV, Swanson BG. The combined inhibitory effect of lysozyme and high voltage pulsed electric fields on the growth of Bacillus subtilis spores In IFT Annual Meeting: Book of Abstracts. 1995:267.

- Singh GL, Dudheria G, Kumar HJA et al. Application of Pulsed Electric Field for Food Preservation Presented to the MSRamaiah Institute of Technology International Conference on Circuits Control Communication and Computing Bangalore Karnataka, 2016.

- Yeom HW, Streaker CB, Zhang QH, et al. Effects of pulsed electric fields on the quality of orange juice and comparison with heat pasteurization. J Agric and Food Chem. 2000:48:4597-4605.

- Ayhan Z, Yeom HW, Zhang QH, et al. Flavor color and vitamin C retention of pulsed electric field processed orange juice in different packaging materials J Agric Food Chem. 2001:49:669-674.

- Lelieveld HL, Notermans S, De Haan SWH. Food preservation by pulsed electric fields: from research to application Elsevier. 2007.

- Reddy MK, Penchalaraju M. Pulsed electric field technology in food processing industry- a review, Int J Sci Res. 2012:3:1144-1149.