Research Article - Journal of Food Technology and Preservation (2023) Volume 7, Issue 4

Application of biopolymer film for edible coating on fruits and vegetables to increase their shelf life.

Sunita Mishra*, Jagriti Joshi

Department of Food and Nutrition, Babasaheb Bhimrao Ambedkar University, Uttar Pradesh, India

- Corresponding Author:

- Sunita Mishra

Department of Food and Nutrition,

Babasaheb Bhimrao Ambedkar University,

Uttar Pradesh,

India,

E-mail: sunitabbau@gmail.com

Received: 19-May-2023, Manuscript No. AAFTP-23-99355; Editor assigned: 24-May-2023, PreQC No. AAFTP-23-99355 (PQ); Reviewed: 07-Jun-2023, QC No. AAFTP-23-99355; Revised: 31-Jul-2023, Manuscript No. AAFTP-23-99355 (R); Published: 28-Aug-2023, DOI: 10.35841/2591-796X-7.4.182

Citation:Mishra S, Joshi J. Application of biopolymer film for edible coating on fruits and vegetables to increase their shelf life. J Food Technol Pres. 2023;7(4):182.

Abstract

In this study, kiwifruit and apple coated with biopolymer film by dipping method were stored at Room Temperature (RT for 15 days and investigated. The effectiveness of biopolymer coating on all treatment was studied by using physiochemical characteristics such as pH, TSS microbiological testing, morphological changes within the samples by SEM and EDX to find the different elements of composition present in biopolymer coating and in 15 days of storage period. The result indicates minimal changes in physicochemical parameters during the storage period, such as TSS, pH and microbial count of coated samples as compared to uncoated samples. Coating apple and kiwifruit with starch-based biopolymers reduces water loss and prevents microbial growth. The application of biopolymer coating on kiwifruit and apples is useful for increasing the stability of perishable fruits such as kiwifruit and apples.

Keywords

Biopolymer, Emulsifier, Dispersion, Dipping method.

Introduction

Many micronutrients found in fruits and vegetables, including vitamins C and K, minerals, fibre and phytochemicals are particularly good for human health [1]. These are highly perishable food because they wilt, shrivel and degrade over the time, reducing their commercial viability and consumer preference. According to data from India, between 25 and 30 percent of the entire amount of fruits and vegetables produced are wasted during postharvest handling, storage and transportation [2]. This is a serious issue because it severely hurts the economy of the country and the growers' ability to make a living. The desire for fresh, quick foods with health advantages has increased, which has resulted in a significant rise in the marketing of less processed fruits and vegetables [3].

Food preservation is one of the most difficult tasks, especially for fruits and vegetables. There are variety of traditional food preservation techniques to preserve the food, some of them are listed below, canning: It can be time consuming and glass jars can be broken and mostly spoilage can be happen if the lid is not tightly applied, freezing: It helps to preserve the food but some of the vitamins are loss like vitamin B and C, drying: The taste of the food product geta hampered and the texture of the food becomes hard, vacuum: It is one of the most expensive technique of preservation which local vendors cannot afford, waxing: It is mostly used for fruits and vegetables, in this wax is mixed with carcinogenic chemicals which makes a thin coating around the food and helps to increase the shelf life but it was hazardous for health [4].

Kiwis and apples are perishable fruits. Kiwi fruits are very sensitive to ethylene and respiration rates [5]. Kiwifruit is a type of climacteric berry which is very popular amongst the consumer due to its high nutritional values. Kiwifruit is good source of vitamin C, rich in potassium, fibers and low-calorie content. Apple is also a perishable fruit, apple is low in sodium, fats and cholesterol that is why most of the Indian population consumes it. Apple is also a good source of vitamin C and fiber.

In recent years, edible films and coatings have been considered one of the best ways to preserve or extend the shelf life of perishable foods and pose no risk to human health [6]. Biopolymer based film and coating have been the best alternative for plastic packaging materials as they were ecofriendly and non-hazardous to human health. There have been various types of biopolymer-based films and coatings, as mentioned here carbohydrate-based films and coating (cellulose, starch, chitosan), protein-based films and coating (corn zein, whey protein, collagen), lipid-based films and coating (carnauba wax, shellac wax) [7].

For the application of the biopolymer films on the fruits there have been a variety of technique present which are listed as, by dipping method (make the biopolymer solution put it in the beaker and then dip your fruit in it very precisely so that a very thin layer was formed), spraying method (put the solution in the sprayer and then simply spray it on the fruit) and brushing method (use the brush for spreading the film all over the fruit). By this method the fruits and vegetables can be preserved for longer time, also the freshness of the fruits will be maintained and the quality. These biopolymer films and coatings are ecofriendly, biodegradable and best alternative to synthetic films and coatings [8].

Materials and Methods

The biopolymer film was prepared by using organic compounds (corn-starch, gelatine, glycerol, citric acid, distilled water).

• 50 ml of distilled water

• 1.5 g of glycerol

• 10 g of corn starch

• 1.5 g of citric acid

• 3 g of gelatin

Required tool:

• Saucepan

• Spatula

• Beaker

• Tray

• Weighing machine

• Spoon

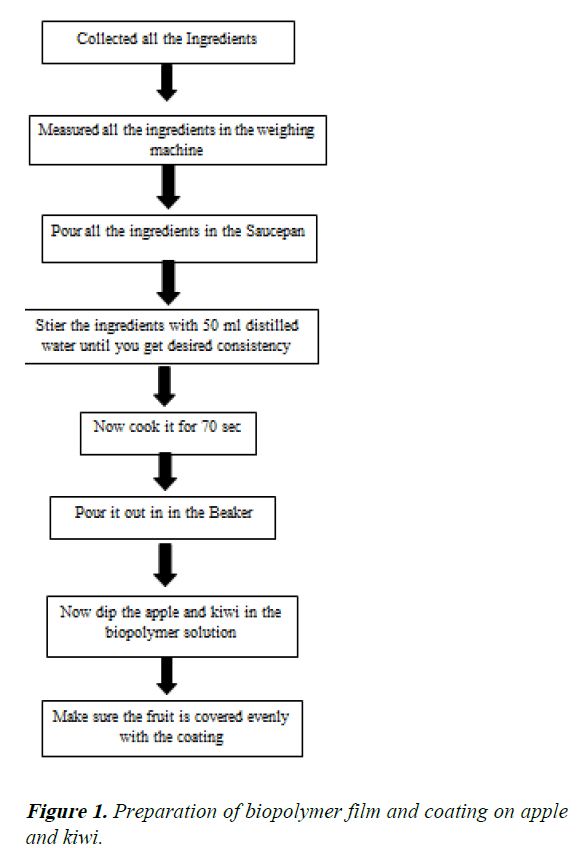

Preparation of biopolymer film and coating on apple and kiwi

The corn starch biopolymer film and coating:

• Glycerine is used as a plasticizer due to its good

mechanical properties and water solubility, which can be

17%-24%, up to 35%.

• Citric acid acts as a solvent to dissolve starch and it helps

starch molecule to remain disrupted after heating.

• Corn starch is used as a thickener, binder, emulsifier and

opacifier or a gelling agent.

• Gelatine has good physical properties such as gel strength,

high dispersibility, low viscosity, dispersion stability and

water retention.

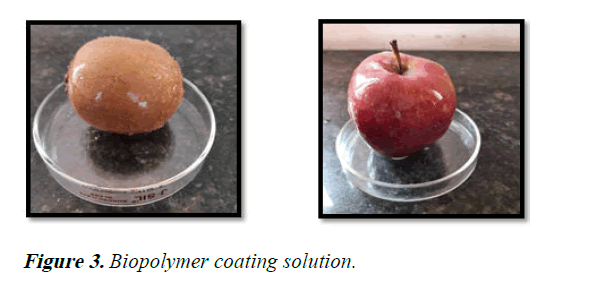

All the ingredients are then combined in their given ratio in a saucepan and stirred it properly until a desired consistency is formed. The mixture was heated on 100°C for 70 sec. The mixture was poured out on the beaker. Then by using the dipping method apply the biopolymer coating on the fruits (dip the apple and kiwi in that biopolymer coating solution) (Figures 1-3) [9].

Characterization

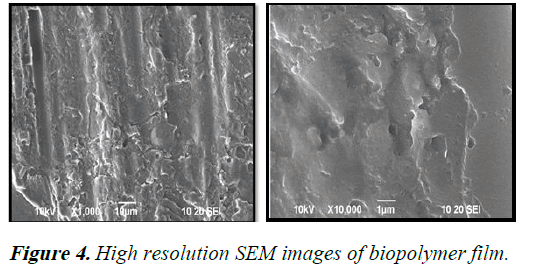

Scanning Electron Microscope (SEM): Scanning Electron Microscopy (SEM) was used to study changes in the polymer and morphological structure and visual analysis provided information on the particle size of Mater-Bi®. The SEM has authorized researchers to examine a much bigger variety of specimens [10].

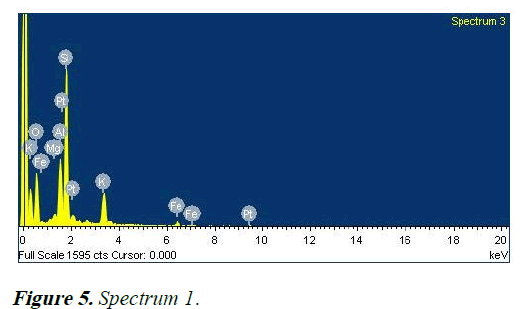

EDX characterization spectrum

Spectrum 1: The below spectrum has multiple visible peaks. The visible peaks confirm the presence of carbon, oxygen, silicon, chlorine, potassium, calcium, bromine in the tested sample.

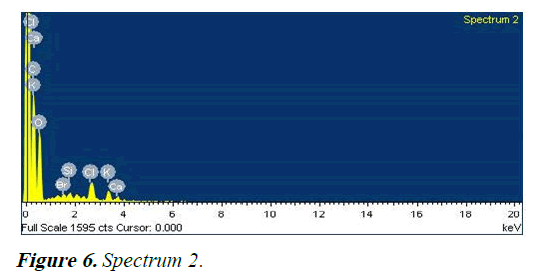

Spectrum 2: The below spectrum has multiple visible peaks. The visible peaks confirm the presence of oxygen, magnesium, aluminium, silicon, potassium, iron, platinum in the tested sample.

Shelf life

For observing the fruits shelf life after coating the apple and kiwi with biopolymer film by using dipping method observed the fruits for 15 days. Put four samples coated apple, without coated apple, coated kiwi and without coated kiwi.

pH measurement: The pH values of all four samples were determined using a pH meter (mini digital pen style pH meter kit, SHAP). The fruit pH test is done by grinding and homogenizing the fruit to make the pulp and for juice, dip the pH meter into the glass and record the reading [11].

Total Suspended Solids (TSS): The TSS content of a fruit is usually obtained by evaluating the brix degree of the fruit. TSS or sugar content measures and contains carbohydrates, organic acids, proteins, fats and minerals in the fruit.

TSS method:

• The surface of the refractometer prism has been cleaned

and dried.

• A small sample is then placed in the prism of the

refractometer.

• Then point the prism in the direction of good light, not

directly at the sun through the eye piece.

• The blue base is centred and glued to the scale position.

• Then record the % brix.

Antimicrobial activity: Prepare universal media (nutrient agar and nutrient broth) for growth of different species of bacteria. These cultures were obtained from the institute of food and nutrition, Babasaheb Bhimrao Ambedkar university, Lucknow, UP, India [12].

• Weigh each ingredient and dissolve in 250 ml of distilled

water.

• Make up to 1000 ml with distilled water. Adjust the pH to

7.0. This is a nutritious soup.

• Autoclave the nutrient stock and transfer aseptically to a

sterile tube.

• For nutrient agar, add 15 g of agar to 1000 ml of nutrient

broth. Heat the mixture to dissolve the agar.

• Divide mixture into flasks and autoclave at 15 psi for 15-20

min.

• After autoclaving, cool the nutrient agar medium to 45°C

and dispense aseptically into sterile petri dishes and tubes,

preparing agar plates, decanters and deep tubes for the

addition of fruit samples.

• For tilting, keep the tube tilted to allow the agar to solidify.

• Nutrient agar plates and tubes and nutrient media are

inoculated with bacterial cultures and incubated for 24

hours.

• Record your observations and results.

Results and Discussion

Scanning electron microscope

The image above shows the microstructure of the biopolymer film and coating. Microstructure is important for understanding the basic structure of biopolymer films. The concentration of precursors used in the synthesis process plays an important role in the morphology of biopolymers. SEM analysis showed a random network-like arrangement of biopolymers with a granular pattern that provides enhanced hydrophobic properties (Figure 4).

EDX characterization spectrum: The EDX analysis was performed during the EDX measurement and the corresponding peaks are shown in spectra 1 and 2 after the completion of the EDX analysis. Current EDS images and tables show the various components present in biopolymer coatings. In spectrum 1, the amounts of C, O, Si, Cl, K, Ca and Br are (49.22, 46.17, 0.49, 1.86, 1.11, 0.43 and 0, respectively 71%) and in spectrum 2, O, Mg, Al, Si, K, Fe and Pt were (46.34%, 1.22%, 9.90%, 28.84%, 7.97%, 2.26% and 3.46%). And these values are given in the Table 1 (Figures 5 and 6) [13].

| Element | Weight% | Atomic% |

|---|---|---|

| C K | 49.22 | 57.7 |

| O K | 46.17 | 40.64 |

| Si K | 0.49 | 0.25 |

| Cl K | 1.86 | 0.74 |

| K K | 1.11 | 0.4 |

| Ca K | 0.43 | 0.15 |

| Br L | 0.71 | 0.13 |

| O K | 46.34 | 62.93 |

| Mg K | 1.22 | 1.09 |

| Al K | 9.9 | 7.97 |

| Si K | 28.84 | 22.31 |

| K K | 7.97 | 4.43 |

| Fe K | 2.26 | 0.88 |

| Pt M | 3.46 | 0.39 |

Table 1. Characteristics of the healthcare workers.

Shelf life

After 15 days observation cut the fruits and gets to find that the coated kiwi was as fresh as that it was harvested yesterday it smelled fresh, the structure was in tacked and without coated kiwi orders bad and not suitable to consumable by the people. The coated apple was fresh and smelled good and without coating apple was in its initial spoilage stage.

pH value: pH plays a very important role in product storage and development because it is an important measure of active acidity, which interferes with product flavor or palatability and influences processing requirements. During the 15-day storage period, pH reduction was observed for all treatments and all treatments were stored at room temperature. The amount of pH of kiwi coated with biopolymer was 3.483 and the kiwi without coating was 4.914 which indicate that biopolymer coating was more effective than non-coated fruit. The amount of pH of apple coated with biopolymer was 4.042 and the apple without coating was 5.410 which indicate that biopolymer coating was more effective than non-coated fruit. The results of all treatments were performed and all treatments showed a positive effect of the biopolymer coating on the samples during the storage period and were significantly higher than the control in maintaining the pH of kiwifruit and apple.

Total Suspended Solids (TSS): The TSS of the 4 samples are calculated after 15 days storage time, the TSS of the coated apple was 11.8 2° brix and the without coated apple was 8.0 2° brix and the TSS of the coated kiwi was 16.7 2° brix and the TSS of without coated kiwi was 14 2° brix. This clearly shows that the TSS of the coated kiwi and coated apple is high then the without coated ones.

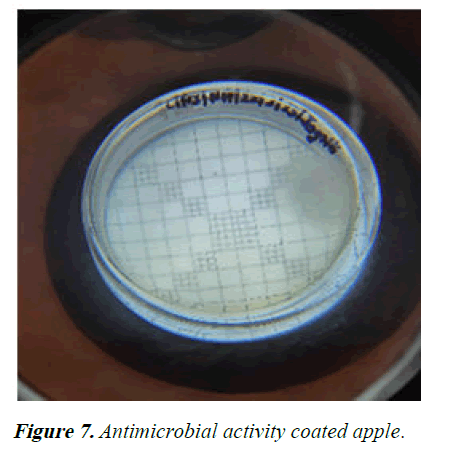

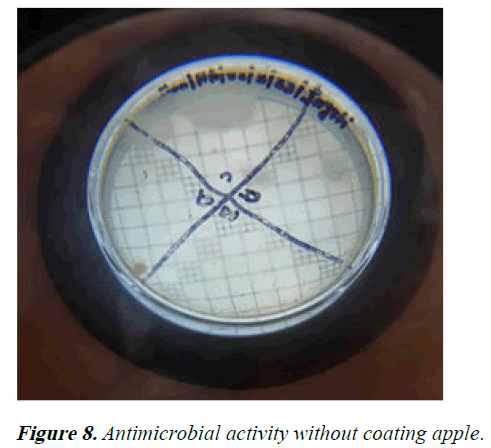

Antimicrobial activity: Microorganism were varying extensively in their degree of susceptibility to anti-bacterial agent. Changes in microbiological quality during storage of kiwi and apple with biopolymer coatings and without coating. In this study, we observed different regions of inhibition in uncoated fruit after the test. The region of inhibition is shown in Figure 7 below. The zones of inhibition of the tested extracts are the coated apple shows a very little amount of microbial growth and the without coated apple have a large amount off microbial growth, the coated kiwi shows a very little amount of microbial growth and the without coated kiwi have a large amount off microbial growth (Figures 8-10).

Conclusion

Kiwi and apple treated with a biopolymer coating (based on starch) used as a preservative inhibits or slows down respiration during storage, reduces the number of microorganisms in apples and kiwis and shortens the ripening period of the fruits by 10-15 days. The physio-chemical parameters of the untreated samples were significantly altered, further affecting the stability of the preservation process. The pH, TSS, morphological changes and microbial counts of the untreated samples were significantly changed after 15 days of storage due to the rate of respiration, transpiration and microbial growth. However, the biopolymer coated samples delayed the ripening of kiwifruit and apple, decreased the pH and maintained the TSS value during the storage period. Bacterial counts of biopolymer-coated kiwifruit and apples were maintained throughout shelf life and biopolymer coating was more effective on kiwifruit than on apple. Applying a biopolymer coating to kiwifruit and apples has been proven to help extend the shelf life and maintain the quality of kiwifruit and apples.

Acknowledgement

I would like to thank the faculty of food and nutrition, Babasaheb Bhimrao Ambedkar university, Lucknow and professor Suntia Mishra, dean and director, food and nutrition, school of home science, Babasaheb Bhimrao Ambedkar university for supporting and providing all possible resources to undertake this research work.

References

- Felicia WX, Rovina K, Nur’Aqilah MN, et al. Recent advancements of polysaccharides to enhance quality and delay ripening of fresh produce: A review. Polymers. 2022;14(7):1341.

[Crossref] [Google Scholar] [PubMed]

- Basumatary IB, Mukherjee A, Katiyar V, et al. Biopolymer-based nanocomposite films and coatings: Recent advances in shelf-life improvement of fruits and vegetables. Crit Rev Food Sci Nutri. 2022;62(7):1912-35.

[Crossref] [Google Scholar] [PubMed]

- Ojeda GA, Sgroppo SC, Zaritzky NE. Application of edible coatings in minimally processed sweet potatoes (Ipomoea batatas L.) to prevent enzymatic browning. Intern J Food Sci Technol. 2014;49(3):876-83.

- Singh DP, Packirisamy G. Biopolymer based edible coating for enhancing the shelf life of horticulture products. Food Chem Molec Sci. 2022;4:100085.

- Passafiume R, Gaglio R, Sortino G, et al. Effect of three different aloe vera gel-based edible coatings on the quality of fresh-cut “Hayward” kiwifruits. Foods. 2020;9(7):939.

[Crossref] [Google Scholar] [Pubmed]

- Xing Y, Yang H, Guo X, et al. Effect of chitosan/Nano-TiO2 composite coatings on the postharvest quality and physicochemical characteristics of mango fruits. Sci Horticult. 2020;263:109135.

- Ruggero F, Carretti E, Gori R, et al. Monitoring of degradation of starch-based biopolymer film under different composting conditions, using TGA, FTIR and SEM analysis. Chemosphere. 2020;246:125770.

[Crossref] [Google Scholar] [PubMed]

- Mishra S, Parveen Z. Morphological and proximate analysis of orange (Citrus scinesis) peel and tomato (Solanum lycopersicum). European J Nutri Food Safe. 2021;13(5):98-105.

- Srivastava T, Mishra S. Proximate analysis and organoleptic properties of therapeutic kadha tablet for immunity booster. J Ayur Integr Med Sci. 2022;7(6):99-104.

- Patel M, Mishra S, Verma R, et al. Synthesis of ZnO and CuO nanoparticles via sol gel method and its characterization by using various technique. Disc Mater. 2022;2(1):1.

- Goutam M, Dhaliwal HS, Mahajan B. Effect of pre-harvest calcium sprays on post-harvest life of winter guava (Psidium guajava L.).J Food Sci Technol. 2010;47:501-6.

[Crossref] [Google Scholar] [PubMed]

- Patel M, Firdaus MA, Mishra S. Influence of ZnO and CuO nanoparticle on the shelf life and physiochemical properties of guava (Psidium guajava) fruits and juice. J Food. 2022;20(1):385-93.

- Zia P, Sunita M, Sneha S. Extraction of natural colour from beet root (Beta vulgaris) its phytochemical analysis and antibacterial activity. EAS J Nutrit Food Sci. 2021;3(4):80-5.