Research Article - Journal of Food Technology and Preservation (2020) Volume 4, Issue 2

Optimization of low-sugar polygonatum jam production process by response surface methodology.

Feng Hua, Zhang Jinli and Wu Peng*College of Food Science and Engineering, Shandong Agricultural University, China

- *Corresponding Author:

- Wu Peng

College of Food Science and Engineering

Shandong Agricultural University

China

Tel: 18764816610

E-mail: 806818828@qq.com

Accepted Date:13 March, 2019

Citation: Feng Hua, Zhang Jinli, Wu Peng. Optimization of low-sugar polygonatum jam production process by response surface methodology. J Food Technol Pres 2018;3(1):4-12.

Abstract

Polygonatum jam was used as the main raw material in this experiment, on the basis of the singlefactor experiment, the interaction of xylitol, citric acid, CaCl2, low-methoxy pectin was investigated according to Box-Benhnken design. Took the sensory score and textural properties as indicators to determine the optimum parameters of making low-sugar polygonatum jam. The results showed that the ideal parameters to product low-sugar polygonatum jam were as follows: xylitol 9.28%, citric acid 0.05%, CaCl2 0.51%, and low-methoxy pectin 1.02%. The sensory index of verification experiment was 95.7 which was basically consistent with the theoretical value 95.1. It revealed that the result optimized by response surface analysis is instructive.

Keywords

Low-sugar, Polygonatum, Textural properties, Response surface methodology.

Introduction

Polygonatum sibiricum, a genus of the family Liliaceae, including Polygonatum kingianum Coll. Et Hemsl, Polygonatum sibiricum Red and Polygonatum cyrtonema Hua. There are more than 60 species in the world and distributed throughout the temperate Northern Hemisphere such as China, Japan, Korea, India, Russia, Europe and North America [1]. Most of Polygonatum plants grow in moist and shady places, typically in forests or bushes with thick and fertile soil. There are 31 species in China, which are widespread in vast areas except the southern tropics. The earliest recording of the use of Polygonatum plants is in The Chinese pharmacopoeia, and the Polygonatum sibiricum is considered to be the “Top grade” herbs in Shennong Bencao Jing (100 BCE-200 CE, Qin and Han Dynasties) due to their life span-prolonging effect and nontoxicity [2,3]. Polygonatum sibiricum is a commonly used Chinese herbal medicine included in the 2015 editions of TCP [4]. Polygonatum sibiricum have a variety of pharmacological properties such as anti-diabetic [5], anti-inflammatory [6], antiatherosclerosis [7] and bone protective effects [8]. Polygonatum plants are also a kind of medicinal and edible homologous plant widely used by the people in the folk, and the Polygonatum cyrtonema Hua which in the Jiuhua Mountain area of Anhui Province. With the gradual deepening of pharmacological effects, chemical constituents and clinical research of Polygonatum, the new drug research pays more attention on the active parts and active ingredients [9].

Polygonatum plants are also used as functional food in various ways. The rhizomes are often cooked with meat or porridge, made into tea or medicated wine and consumed as fruit or vegetables. The young leaves and stems are also used as vegetables in some places [10,11]. It can be processed into nourishing foods, such as the Polygonatum Candied Fruit, the Polygonatum Tonic, the Polygonatum Oral Liquid, the Polygonatum Granules, etc. This experiment makes full use of Polygonatum sibiricum to develop a convenient and easy-to-eat product, low-sugar Polygonatum jam, which expands the variety of Polygonatum food. For some special populations such as high blood pressure and diabetes, there is an inevitable concern about the amount of sucrose in the jam products [12-14]. As a functional sweetener, xylitol can participate in human metabolism after entering the bloodstream. It can penetrate into cells without insulin, and has a fast metabolic rate, which will not cause blood sugar rise. It is a nutrient type sucrose substitute suitable for diabetic patients. Xylitol also results in benefiting the liver, anti-caries, weight loss, etc. [15-17]. In addition, Polygonatum sibiricum is often processed by repeated cooking and drying until the rhizomes become black, soft and sweet in order to enhance their tonic function and avoid throat irritation. This experiment took Polygonatum jam as the main raw material, added xylitol, low-methoxy pectin and citric acid, etc. to make low-sugar yellow essence sauce with sour and sweet taste and rich nutrition, in order to enhance the nutritional function of the products. On the basis of the single-factor experiment, the optimal process formula of Polygonatum jam was optimized by Box-Behnken experiment, and the nutritional value of Polygonatum was fully utilized to develop a low-sugar Polygonatum jam that combines deliciousness and nutrition. It not only solves the problem of excessive sugar content in jam products for exceptional populations, but also has important significance for discovering and developing Chinese herbal medicine resources.

Materials and Methods

Materials and equipment

Polygonatum sibiricum was purchased from Jiuhua Mountain, China; Citric Acid and CaCl2 were purchased from Chengdu Kelong Chemical Reagent Factory (Chengdu, China); Lowmethoxy Pectin and Xanthan Gum were purchased from Shandong Bufeng Fermentation Co., Ltd. (Shandong, China); Xylitol were purchased from Shandong Mifutang Food Co., Ltd. Company (Shandong, China). All the materials were of food grade.

Experimental methods

Polygonatum jam preparation: Polygonatum [18] with moderate maturity, no damage and decay was used for jam. Put the Polygonatum into the rice cooker and cooked at atmospheric pressure for 8 h, and steaming was performed for 12 h [19], after removing, add water and beat. According to a definite ratio, citric acid, xylitol and CaCl2 were added, and the mixing was continued during the addition and recorded Concentration time. Then pour the dissolved low-methoxy pectin into the puree and stir for a while. After thoroughly cleaning the glass bottle and cap with water, sterilize with water vapor at a temperature of 100°C for 10 min. After the jam was out of the pan, quickly filled the can and tightened the cap. The filling time of each pot of jam should not exceed 30 minutes, and the temperature of the jam should not be lower than 80-90°C. The low-sugar Polygonatum jam was sterilized at 95-100°C for 30 min. After being taken out, it was allowed to cool at room temperature for 3 h, and stored at low temperature.

Single factor experiment: Four main factors affecting the quality of low-sugar Polygonatum jam were selected: xylitol, citric acid, CaCl2, and low-methoxy pectin. The sensory score was used as the evaluation standard to determine the optimal dosage of the four factors [20]. The addition amount of fixed low-methoxy pectin, CaCl2 and citric acid was 1%, 0.5%, and 0.06%. When the amount of xylitol added was 3, 6, 9, 12, and 15%, the effect on the sensory score and texture characteristics of low-sugar Polygonatum jam [21].

The amount of xylitol, low-methoxy pectin and CaCl2 added was 9%, 1%, and 0.5%. When the amount of citric acid was 0.03, 0.06, 0.09, 0.12, and 0.15%, effect on sensory scores and texture characteristics of low-sugar Polygonatum jam.

The added amount of xylitol, low-methoxy pectin and citric acid were 9%, 1%, and 0.06%. When the amount of CaCl2 added was 0.25, 0.50, 0.75, 1.00, and 1.25%, effect on sensory scores and texture characteristics of low-sugar Polygonatum jam.

The addition amount of fixed xylitol, CaCl2 and citric acid was 9%, 0.5% and 0.06%. When the addition amount of lowmethoxy pectin was 0.25, 0.50, 0.75, 1.00 and 1.25, the effect of sensory score and texture characteristics of low-sugar Polygonatum jam.

Box-benhnken center combination experiment design: Response surface methodology was used for the optimization of variables in the present study which involves design of experiment, selection of variables levels in experimental runs, mathematical models fitting and selection of optimized levels of variables with respect to optimize response levels. A central composite design (CCRD) was used to study the effect of four independent variables at three levels on the response pattern and to determine the optimum combination of variables. The independent variables optimized were A (xylitol addition), B (citric acid addition), C (CaCl2 addition), D (low-methoxy pectin addition) for dependent response Y (sensory score). The experimental factors and the horizontal coding are given in Table 1.

Table 1: Factor level and coding of Box-Behnken center combination experiment design.

| Factor | Coding level | ||

|---|---|---|---|

| -1 | 0 | 1 | |

| A) Xylitol addition (%) | 6 | 9 | 12 |

| B) Citric acid addition (%) | 0.03 | 0.06 | 0.09 |

| C) CaCl2 addition (%) | 0.25 | 0.5 | 0.75 |

| D) Low-methoxy pectin addition (%) | 0.75 | 0.1 | 1.25 |

Sensory evaluation: Sensory evaluation table was prepared by standard, and combined with texture and flavor of low-sugar Polygonatum jam with slight modifications. Sensory properties of jam were evaluated by a panel of 20 semi-trained members. Panelists were formed for descriptive analysis for sensory evaluation of jam and then performed sensory score on the product, the percentage rating scored according to the scoring standard. Overall acceptability of jam was calculated from the average of all the parameters [22]. The sensory evaluation table is given in Table 2.

Table 2: Sensory evaluation standards of low-sugar Polygonatum jam.

| Rating item | Grading | Score |

|---|---|---|

| Organizational status (30 points) | Good gelatinity, no sugar, water precipitation, uniform and non-dispersive | 20-30 |

| Good gelatinity, a small amount of sugar and water are precipitated, basically uniform, slightly dispersed | 10-19 | |

| General gelatinity, more precipitation than polysaccharides, water, uneven, scattered | 1-9 | |

| Taste (30 points) | Moderate sweet and sour, pure and delicate taste, good toughness | 20-30 |

| Slightly acidic or sweet, the taste is purer and finer, and the toughness is good. | 10-19 | |

| The ratio of sweet and sour is uncoordinated, the taste is rough, and the toughness is generally | 1-9 | |

| Color (15 marks) | Light Polygonatum, shiny, no browning | 10-15 |

| Light Polygonatum, brighter color | 6-9 | |

| Dark color, browning is serious | 1-5 | |

| Aroma (15 marks) | Rich in Polygonatum | 10-15 |

| Polygonatum is more intense | 6-9 | |

| Polygonatum is not obvious | 1-5 | |

| Spreadability (10 points) | Easy to apply, even and smooth coating | 8-10 |

| Easy to apply, even coating, not smooth | 4-7 | |

| Easier to apply, but the coating is incoherent | 1-3 |

Jam texture: Texture Analyzer was used to measure the texture of the low-sugar Polygonatum jam via using probe P 0.5 rig, and each sample was experimented 3 times. Thetextural studies were conducted at descent speed of 1.0 mm/s, test speed of 1.0 mm/s. Hardness, spreadability, cohesion, viscosity and other indicators can be obtained according to the texture chart.

Data analysis: The data were sorted using Microsoft Excel 2007 software, and obtained from experiments was analyzed for analysis of variance (ANOVA) and regression models using Stat-Ease software (Design-Expert.8.0.6). A second-order polynomial was fitted to the data to obtain regression equations. The terms in the regression equations were examined for statistical significance. The significance of the models was analyzed using model analysis and coefficient of determination (R2) value, lack of fit F-value and model Fvalue. Response surface graphs were generated with the help of commercial statistical package. The response surface graphs obtained from experimental data showed the effect of variation in independent variables on the responses.

Results and Analysis

Single factor experiment results and analysis

Effect of xylitol addition on sensory score: Xylitol was used to increase the sweetness of the Polygonatum jam, and the amount added during the experiment was 3, 6, 9, 12, and 15%. The experimental results are displayed in the Table 3 and comparing products by sensory evaluation and the texture analysis can be obtained: when the xylitol content was 3%, the product taste was poor, and the product was not easy to apply. When the amount of xylitol added was in the range of 6% to 9%, the sweetness and sourness of the Polygonatum jam were suitable, and the spreadability was good. As the amount of xylitol increased, the application performance of the Polygonatum jam increased. Due to the caramelization process of the sugar, the color of the prepared Polygonatum jam was deepened, the flavor of the Polygonatum jam was increased, the viscosity was increased, the good tissue morphology [23] was maintained, and the xylitol was excessive and the viscosity was too high. So, according to the comprehensive analysis, the content of xylitol was determined as 6%-9%. Probably because the sugar content was 3%, the sugar concentration in the system was low, it cannot be tightly combined with water, the water was analyzed, the spreadability was poor, and the quality was degraded. When the sugar content of the system is 15%, the sugar concentration is too high, and the Polygonatum jam is dehydrated, so that the sample is electrically neutralized, a gel can be formed, the viscosity of the system is increased, and the spreadability is lowered.

Table 3: Effect of xylitol addition on quality of Polygonatum jam.

| xylitol addition/% | Hardness/g | Spreadability/g·s-1 | Cohesion/g | Viscosity/Pa·s-1 | Sensory score/fraction |

|---|---|---|---|---|---|

| 3 | 13.80 ± 0.21b | 261.40 ± 60.64b | 5.27 ± 0.12e | 4.79 ± 0.05e | 61.33 ± 1.33d |

| 6 | 12.00 ± 0.49c | 206.93 ± 38.80c | 6.10 ± 0.09d | 7.76 ± 0.10d | 75.33 ± 12.33b |

| 9 | 10.77 ± 0.30d | 189.37 ± 11.02d | 6.73 ± 0.04c | 9.85 ± 0.01c | 83.67 ± 2.33a |

| 12 | 15.23 ± 0.30a | 260.47 ± 36.58b | 7.30 ± 0.13b | 13.12 ± 0.01b | 79.33 ± 6.33ab |

| 15 | 15.17 ± 0.82a | 274.23 ± 9.40a | 8.37 ± 0.06a | 17.64 ± 0.20a | 69.67 ± 17.33c |

Note: Based on 150 g Polygonatum jam, all results are expressed as mean ± standard deviation. Different lowercase letters in the same column indicate significant difference (p<0.05), and the same letter indicates no significant difference (p>0.05).

Effect of citric acid addition on sensory score: Although the low-sugar Polygonatum jam has low-sugar content, it still has a sweet taste, while the Polygonatum contains insufficientacid and has to be adjusted by adding an appropriate amount of acidulant. Citric acid was used as citric acid to improve the mouthfeel of the Polygonatum jam [24] and the gel effect of the jam.

The amounts of citric acid added were 0.03, 0.06, 0.09, 0.12, and 0.15%. Through sensory evaluation and the texture analysis, it can be seen that when the amount of citric acid added in the Polygonatum jam was in the range of 0.06% to 0.09%, the taste of the Polygonatum jam was better, and the taste was biased when the amount of citric acid added was in the range of 0.12% to 0.15%. As the content of citric acid increases, it was easy to apply. This was because the number of H+ increases, which were beneficial to the combination of thickener and sugar solution, which reduces the repulsive force between chains and forms a stable and orderly network structure. Decrease, performance of the Polygonatum jam was increased. However, the citric acid content was excessively increased, and there was a slight water seepage phenomenon. The hand feels certain elasticity but was brittle, and the texture was characterized by a low gel breaking strength, which may be due to the fact that pectin was in a higher acidity and partially can be calcium. The combined free shuttle group binds to hydrogen, hindering the formation of a gelled calcium bridge. Therefore, optimum addition amount of citric acid was determined to be 0.06% (Table 4).

Table 4: Effect of citric acid addition on quality of Polygonatum jam.

| Citric acid addition amount/% | Hardness/g | Spreadability/g s-1 | Viscosity/Pa s-1 | Cohesion/g | Sensory score/fraction |

|---|---|---|---|---|---|

| 0.03 | 13.80 ± 0.28c | 286.93 ± 115.04a | 6.33 ± 0.26c | 17.44 ± 13.79b | 77.00 ± 13.00b |

| 0.06 | 12.23 ± 0.12d | 242.03 ± 128.56cd | 10.06 ± 0.36a | 24.73 ± 20.69a | 90.00 ± 4.00a |

| 0.09 | 16.77 ± 0.32a | 224.53 ± 506.90d | 7.7 ± 0.04b | 24.20 ± 1.63a | 79.33 ± 9.33b |

| 0.12 | 14.53 ± 1.00bc | 261.73 ± 12.41bc | 6.3 ± 0.21c | 12.22 ± 4.07c | 74.67 ± 2.33b |

| 0.15 | 15.47 ± 1.52ab | 268.17 ± 62.74ab | 5.33 ± 0.04d | 7.21 ± 0.43c | 63.33 ± 2.33c |

Different lowercase letters in the same column indicate significant difference (p<0.05), and the same letter indicates no significant difference (p>0.05).

Effect of the addition of CaCl2 on sensory score: The calcium ion in CaCl2 can react with low-methoxy pectin to constitute a gel, which can improve the viscosity and gel effect of the jam. In this experiment, the amount of CaCl2 added was 0.25. 0.50, 0.75, 1.00, 1.25%. Through sensory evaluation and the texture analysis, it can be seen that when the amount of CaCl2 added in the Polygonatum jam was in the range of 0.50% to 0.75%. The taste and gel effect of the Polygonatum jam was better. In the experiment, when the concentration of CaCl2 was low, the gel was not formed or the gel formation was extremely unstable. With the increase of the addition amount, the gelatin gel was soft at 0.50%, and the sample continues to increase with the concentration. The hardness is slowly declining. In addition, the cohesive force increases the increase of the concentration of CaCl2, and reached the maximum when the addition amount was 0.50%. After that, the gel crushing strength decreases inversely with the increase of the concentration, and finally the water seepage was pre-gel phenomenon, and the texture characteristics greatly destroyed. Therefore, optimum addition amount of CaCl2 was determined to be 0.5% (Table 5).

Table 5: Effect of CaCl2 addition on quality of Polygonatum jam.

| CaCl2 addition amount/% | Hardness/ | Spreadability/g·s-1 | Viscosity/Pa s-1 | Cohesion/ | Sensory score/fraction |

|---|---|---|---|---|---|

| 0.25 | 13.80 ± 0.13ab | 276.10 ± 82.93ab | 7.10 ± 0.04b | 19.01 ± 0.05b | 69.67 ± 25.33cd |

| 0.5 | 14.93 ± 0.05a | 240.53 ± 10.29c | 9.07 ± 0.26a | 24.48 ± 0.45a | 88.67 ± 9.33a |

| 0.75 | 13.90 ± 0.16ab | 266.27 ± 124.56b | 6.40 ± 0.19b | 14.61 ± 0.80c | 80.66 ± 4.33b |

| 1 | 12.47 ± 0.16bc | 261.93 ± 40.34b | 6.20 ± 0.21b | 11.93 ± 0.27c | 74.00 ± 13.00bc |

| 1.25 | 11.90 ± 3.16c | 285.07 ± 105.44a | 6.50 ± 0.63b | 14.95 ± 24.69bc | 63.67 ± 16.33d |

Different lowercase letters in the same column indicate significant difference (p<0.05), and the same letter indicates no significant difference (p>0.05).

Effect of low-methoxy pectin addition on sensory score: In a limited solvent, as the concentration of pectin increases, the number of pectin molecules per was increased, andthe gap between the pectin gradually decrease, so that the gel texture formed becomes hard and the crushing strength enhancement. At the same time, due to the concentration of pectin.

The rise of the carboxyl group per unit volume increases the probability of binding to calcium ions, and the binding with calcium ions is more sufficient, which can give the gel better textured characteristics to some extent, but the gel tends to appear as the concentration increases. The texture is hard and brittle, and the gel becomes brittle, that is, one of the signs of reduced elasticity, which is clearly reflected in the texture measurement [25]. It can be seen that the concentration of pectin is one of the crucial factors affecting the texture of pectin gel. The low-methoxy pectin addition amount was selected to be five levels of 0.25, 0.50, 0.75, 1.00, and 1.25%. It can be seen from Table 6 that the sensory score of Polygonatum jam was the highest when the amount of the lowmethoxy pectin was 1.00%, and the gelatin effect of the Polygonatum jam was good and the taste was pure. Continue to add low-methoxy pectin, the sensory score of the jam decreased with the increase of low-methoxy pectin, and the taste was worse. Therefore, the optimum addition amount of the low-methoxy pectin was determined to be 1.00%.

Table 6: Effect of low-methoxy pectin addition on quality of Polygonatum jam.

| Low-methoxy pectin addition/% | Hardness/g | Spreadability/g s-1 | Viscosity/Pa s-11 | Cohesion/g | Sensory score/fraction |

|---|---|---|---|---|---|

| 0.25 | 9.87 ± 0.49d | 318.20 ± 119.91a | 11.67 ± 0.65a | 15.37 ± 8.93e | 60.67 ± 4.33d |

| 0.5 | 11.77 ± 0.49c | 277.90 ± 136.09b | 10.03 ± 0.30b | 19.58 ± 0.53d | 68.00 ± 7.00c |

| 0.75 | 14.67 ± 3.52b | 260.03 ± 128.10b | 8.97 ± 0.06b | 24.14 ± 1.98c | 80.67 ± 16.33b |

| 1 | 16.70 ± 0.19a | 261.53 ± 306.30b | 6.77 ± 0.32c | 27.89 ± 1.83b | 87.67 ± 6.33a |

| 1.25 | 18.17 ± 0.41a | 260.30 ± 76.63b | 6.60 ± 1.33c | 31.95 ± 5.07a | 79.33 ± 6.33b |

| Different lowercase letters in the same column indicate significant difference (p<0.05), and the same letter indicates no significant difference (p>0.05). | |||||

Response surface experiment results analysis

Response surface experiment design and results: According to the results of the single factor experiment, the experimental protocol and results obtained by Design-Expert 8.0.6 software are shown in Table 7. Sensory score of low-sugar Polygonatum jam is the response value, xylitol (A), citric acid (B), CaCl2 (C) and low-methoxy pectin (D) was a four-factor and three-level experimental scheme for the independent variable.

Table 7: Box-Behnken Design and results of response surface experiments.

| Experimental coding |

Factor coding level | Sensory score/fraction | |||

|---|---|---|---|---|---|

| A | B | C | D | ||

| 1 | 0 | -1 | 1 | 0 | 83 |

| 2 | 1 | 1 | 0 | 0 | 79 |

| 3 | 1 | 0 | -1 | 0 | 87 |

| 4 | 0 | 1 | 1 | 0 | 78 |

| 5 | 0 | 0 | 1 | -1 | 82 |

| 6 | 0 | 0 | -1 | 1 | 84 |

| 7 | 0 | -1 | 0 | -1 | 81 |

| 8 | 0 | 0 | 0 | 0 | 94 |

| 9 | 1 | 0 | 1 | 0 | 85 |

| 10 | -1 | 0 | 0 | -1 | 77 |

| 11 | -1 | 1 | 0 | 0 | 80 |

| 12 | 0 | 1 | 0 | 1 | 78 |

| 13 | 0 | 1 | -1 | 0 | 75 |

| 14 | 1 | 0 | 0 | 1 | 82 |

| 15 | 0 | 0 | 1 | 1 | 87 |

| 16 | 0 | -1 | 0 | 1 | 84 |

| 17 | -1 | 0 | -1 | 0 | 81 |

| 18 | 1 | -1 | 0 | 0 | 87 |

| 19 | -1 | 0 | 0 | 1 | 83 |

| 20 | 0 | 1 | 0 | -1 | 74 |

| 21 | 0 | 0 | -1 | -1 | 82 |

| 22 | 0 | -1 | -1 | 0 | 84 |

| 23 | -1 | -1 | 0 | 0 | 86 |

| 24 | 0 | 0 | 0 | 0 | 96 |

| 25 | 1 | 0 | 0 | -1 | 86 |

| 26 | 0 | 0 | 0 | 0 | 93 |

| 27 | -1 | 0 | 1 | 0 | 87 |

| 28 | 0 | 0 | 0 | 0 | 96 |

| 29 | 0 | 0 | 0 | 0 | 94 |

Response surface variance analysis results: Using the Design Expert 8.0.6 software to perform the quadratic polynomial regression fitting on the experimental data of Table 3, the regression model is obtained: Y=94.60+1.00A-3.42B +0.75C+1.33D-0.50AB-2.00AC-2.50AD+1.00BC+0.25BD +0.75CD-4.47A2-8.34B2-5.09C2-6.97D2, the variance analysis was performed on the experimental results by Box- Benhnken response surface analysis. Table 8, the significance of the influence of each factor of the regression equation on the sensory score is determined by the F-value. If the probability p-value is small, it indicates that the corresponding factor has a higher degree of significance.

Table 8: Results of ANOVA of response surface analysis.

| Factor | Sum of square | Degree of freedom | Mean square | F-value | P-value | Significant |

|---|---|---|---|---|---|---|

| A | 12 | 1 | 12 | 3.94 | 0.067 | |

| B | 140.08 | 1 | 140.08 | 46.02 | <0.0001 | ** |

| C | 6.75 | 1 | 6.75 | 2.22 | 0.1586 | |

| D | 21.33 | 1 | 21.33 | 7.01 | 0.0191 | * |

| AB | 1 | 1 | 1 | 0.33 | 0.5756 | |

| AC | 16 | 1 | 16 | 5.26 | 0.0379 | * |

| AD | 25 | 1 | 25 | 8.21 | 0.0125 | * |

| BC | 4 | 1 | 4 | 1.31 | 0.2709 | |

| BD | 0.25 | 1 | 0.25 | 0.082 | 0.7786 | |

| CD | 2.25 | 1 | 2.25 | 0.14 | 0.4044 | |

| A2 | 129.41 | 1 | 129.41 | 42.51 | <0.0001 | ** |

| B2 | 451.35 | 1 | 451.35 | 148.27 | <0.0001 | ** |

| C2 | 168.16 | 1 | 168.16 | 55.24 | <0.0001 | ** |

| D2 | 314.82 | 1 | 314.82 | 103.42 | <0.0001 | ** |

| model | 943.59 | 14 | 67.4 | 22.14 | <0.0001 | ** |

| Residual | 42.62 | 14 | 3.04 | |||

| Degree of misfit | 35.42 | 10 | 3.54 | 1.97 | 0.2687 | |

| Pure error | 7.2 | 4 | 1.8 | |||

| sum | 986.21 | 28 |

Note: **significant at P<0.0001; *significant at P<0.05

Table 8 demonstrates that the model has an F-value of 22.14 and p-value<0.0001, indicating that the model is very significant, reflecting that the experiment is consistent with the experimental results at the experiment site. The F-value of the misfit is 1.97, and the p-value is 0.2687>0.05, which is not significant, indicating that the regression equation has a good fit in the regression space. The linear relationship between each factor and the response value is obvious. This model can be used to analyze and predict the sensory score of low-sugar Polygonatum jam.

When the p-value <0.05, the model factor is significant, so B, D, AC, AD, A2, B2, C2, D2 are significant. AC and AD are significant, indicating that the interaction of xylitol with CaCl2, xylitol and low-methoxy pectin have an effect on the sensory score of low-sugar Polygonatum jam. From the F-value experiment, the order of influence of each factor on the sensory evaluation of low-sugar Polygonatum jam was: citric acid addition amount>low-methoxy pectin addition amount>xylitol addition amount>CaCl2 addition amount.

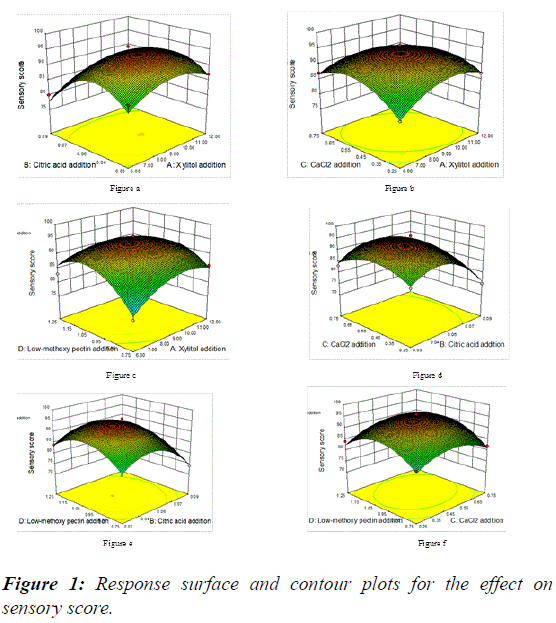

Response surface analysis: The response surface graph is a three-dimensional surface graph composed of sensory score Y for each experimental factor. From the surface map, the optimal parameters and the interaction between the various parameters can be found. The three-dimensional surface curve composed of xylitol addition amount (A), citric acid addition amount (B), CaCl2 addition amount (C) and low-methoxy pectin addition amount (D) is shown in Figure 1.

According to the 3D surface map shown in Figure 1, the influence of various factors on the sensory score and the interaction between the various factors can be analyzed. It can be seen from the figure that when xylitol, citric acid, CaCl2, low-methoxy pectin .When any two factors between methoxy pectin are zero level, the sensory score increases with the increase of the other two factors. After reaching a certain value, the surface slowly decreases, the curves of graphs b and c are steeper than the other two. The steep surface indicates that the interaction between xylitol and CaCl2, xylitol and lowmethoxy pectin are more obvious, consistent with the analysis of variance.

It can be seen from Figure 1 that the response surface pattern is curved surface with convex surface and a downward opening, indicating that there is an extreme value of the sensory score Y, which is the highest point of the response surface, and the optimal action point of each experimental factor is located at the experimental design value. Within the range, with the addition of citric acid and the amount of CaCl2 added, with the increase of xylitol addition, the addition of low-methoxy pectin increased, the sensory score increased first and then decreased. Thus, it can be seen that proper xylitol and low-methoxy pectin can improve the taste of the low-sugar Polygonatum jam. The contour map can determine the significance of the interaction. The contour map tends to ellipse, and the interaction is significant. Otherwise, it is not significant. The contour maps of AC and AD interactions are elliptical, indicating the interaction between AC and AD. The interaction between the two is significant (Figure 1b and 1c). The contour maps of AB, BC, BD, and CD tend to be circular, indicating that the interaction is not significant, as shown in Figure 1a, 1d, 1e and 1f. The degree of density of the contour line can determine the influence of various factors on the sensory score. The denser the contour line, the greater the influence, and vice versa, the effect of the amount of citric acid added (B) on the sensory quality of low-sugar Polygonatum jam. The amount of xylitol added (A), the amount of CaCl2 added (C), the amount of lowmethoxy pectin added (D), and the amount of low-methoxy pectin added (D) to low-sugar Polygonatum jam. The effect of sensory quality is greater than the amount of xylitol (A) and the amount of CaCl2 (C). The amount of xylitol added (A) has a lower effect on the sensory quality of low-Polygonatum Polygonatum jam than CaCl2. The effect of the addition amount (C) is large, which is consistent with the results of the analysis of variance.

Model verifications: Numerical optimization of processing variables was done by using Design-Expert (8.0.6) software. Optimum values for processing variables were obtained after assigning certain constraints processing variables. Optimum values of processing variable and responses are as follows: xylitol 9.28%, citric acid 0.05%, CaCl2 0.51%, and lowmethoxy pectin 1.02%. Confirmative test for verification of model was carried out using optimum levels of independent variables. And the actual values obtained at optimum conditions of processing variables were 95.1. In order to verify the reliability of the response surface results, the confirmatory experiment of the low-sugar Polygonatum jam was carried out according to the optimal conditions obtained by the experiment. After three parallel experiments, the sensory score of the low-sugar Polygonatum jam were 95, 96, and 96. The average sensory score was 95.67, and the error from the theoretical value was within 1%. Thus, the confirmative test validated the experimental results as well as the regression model.

Physical and chemical indicators

According to the measurement method, soluble solids, total acid content, total sugar content and viscosity of the low- Polygonatum Polygonatum jam were measured as shown in Table 9.

Table 9: The physical and chemical indicators of low-sugar Polygonatum jam

| Project | The measurement results |

|---|---|

| Soluble solids (refractometer at 20°C)/(%) | 34.5 |

| Total acid/(g/100 g) | 0.2344 |

| Total sugar/(g/100 g) | 37.82 |

| Viscosity/(Pa/s) | 35 |

Microbial indicators

The total number of bacteria <20/g; the number of coliforms <30/100 g; pathogenic bacteria cannot be detected.

Conclusion

Optimization of processing variables for preparation of lowsugar Polygonatum jam was effectively done using response surface methodology. The regression analysis for modeling of processing variables was used for obtained optimum conditions for desired values of responses such as sensory score. Model validation was done by analyzing various significant statistical aids such as F-value. All these terms revealed the statistical adequacy of the model. It is concluded that the order of influence of various factors on the sensory evaluation of lowsugar Polygonatum jam was as follows: the amount of citric acid added>the amount of low-methoxy pectin added>the amount of xylitol added>the amount of CaCl2 added. Optimum values for the processing parameters were obtained from numerical optimization technique, which also satisfied the criterion of constraints of the responses. The predicted and experimental values were in accord with each other. The results showed that the ideal parameters to product low-sugar Polygonatum jam were as follows: xylitol 9.28%, citric acid 0.05%, CaCl2 0.51%, and low-methoxy pectin 1.02%.

References

- Ai TM. Chinese Medicinal Plants 11 Peking University Medical Press, Beijing, 2014.

- Zhao R, Xu L, Xie M et al. Textual research of Polygonati Odorati Rhizoma. Chin J Exp Tradit Med Formulae. 2017;23(2):227-34.

- Xu H, Lin Q. A review on Huangjing. Shandong J Tradit Chin Med. 2016;35(11):992-5.

- Chinese Pharmacopoeia. One [S]. 2015:306.

- Shu X, Lv J, Chen D et al. Herald J Biochem Bioinform. 2012;1:14-9.

- Debnath T, Park SR, Da HK et al. Antioxidant and anti-inflammatory activity of Polygonatum sibiricum rhizome extracts Asian Pac J Trop Dis. 2013;3(4):308-13.

- Yang JX, Wu S, Huang XL et al. Hypolipidemic Activity and Antiatherosclerotic Effect of Polysaccharide of Polygonatum sibiricum in Rabbit Model and Related Cellular Mechanisms. Evid Based Complement Alternat Med. 2015.

- Zeng GF, Zhang ZY, Lu L et al. Protective effects of Polygonatum sibiricum polysaccharide on ovariectomy-induced bone loss in rats. J Ethnopharmacol. 2011;136(1):224-9.

- Jiang C, Zhang T, Chen C et al. Research progress of Polygonatum and prediction analysis of its quality markers. Chin Traditional Herbal Drugs. 2017;48(1):1-16.

- Wujisguleng W, Liu Y, Long C. Ethnobotanical review of food uses of Polygonatum (convallariaceae) in china. Acta Soc Bot Pol. 2012;81(4):239-44.

- Saboon, Bibi Y, Arshad M et al. Pharmacology and biochemistry of Polygonatum verticillatum: a review. J Coast Life Med. 2016;4(5):406-15.

- Zhou C. Application of xylo-oligosaccharide in biscuit production. Food Science Technol. 2006;11:148-51.

- Li D. Study on the processing technology of sucrose-free yogurt. Nanjing Agricultural University. 2006.

- Zhang H, Wang L, Peng T. Study on the technology of sugar-free bitter soda cracker. Food Industr. 2010;31(1):77-8.

- USA, Business Communications Co Inc. The global market for polyo1s. Int Sugar J. 2002;104:352-4.

- Gong C, Yu C, Zhang Y. Study on the Properties and Application of Functional Sweetener-Xylitol. Chin Food Additives. 2003;5:83-6.

- You X. Xylitol and its function. Food Industr Sci Technol. 2003;8:87-8.

- Yu T. Development of low-sugar compound nutrition fruit and vegetable jam and its storage stability. Inner Mongolia Agricultural University. 2013.

- Yi S, Quan J, Li P et al. Research progress in the processing of Polygonatum sibiricum. Zhonghua J Tradit Chin Med. 2017;32(10):4575-8.

- Wang T. Preparation of jujube clarified juice and comprehensive utilization of its by-products. Jiangnan University. 2005.

- Zhang Z, Zhou H, Zheng X et al. Optimization of Qingqi Liuye Biscuits Formulation. Sci Technol Food Industr. 2018;39(7):152-7.

- Wang X, Duan L, Huo Y. Optimization of Process Formulation of Mung Bean and Lactic Acid Bacteria Beverage. China Brewing. 2014;33(7):153-6.

- Bi Y, Jiang R, Wu X et al. Preparation and Functional Properties of Purple Sweet Potato Anthocyanin. Food Sci Technol. 2015;40(5):94-9.

- Du W. Development of low-sugar red jujube compound jam. Food Res Development. 2008;8:99-100.

- Liu G, Lei J, Zheng R et al. Study on the factors affecting the texture properties of low-methoxyl pectin gel. Food Sci Technol. 2010;35(10):248-51.