Review Article - Journal of Environmental Waste Management and Recycling (2023) Volume 0, Issue 0

Study on assessment of the potential of utilizing lactic acid bacteria and green waste for methane production.

Ankita Suvagiya*, Gira P Mankad, Hetvi Nandaniya, Chandani Chavda

Department of Agriculture, Juangadh Agriculture University, Junagadh, India

- Corresponding Author:

- Ankita Suvagiya

Department of Agriculture,

Juangadh Agriculture University,

Junagadh,

India,

E-mail: sigitasvejelis@vilniustech.lt

Received: 23-March-2023, Manuscript No. AAEWMR-23-98125; Editor assigned: 28-March-2023, PreQC No. AAEWMR-23-98125 (PQ); Reviewed: 11-April-2023, QC No. AAEWMR-23-98125; Revised: 11-May-2023, Manuscript No. AAEWMR-23-98125 (R); Published: 22-Jun-2023, DOI: 10.35841/aaewmr-6.3.141

Citation:Suvagiya A, Mankad GP, Nandaniya H, et al. Study on assessment of the potential of utilizing lactic acid bacteria and green waste for methane production. Environ Waste Management Recyclying. 2023;6(3):141

Abstract

Growing populace has introduced about boom in electricity call for and waste production subsequently it's far of extraordinary need to offer alternative to fueling. This evaluate article includes the figuring out parameters for increasing the performance of a biogas plant. In this article green waste using LAB has been used as substrate for biogas manufacturing which no longer handiest produces greater biogas compared to traditional substrate however additionally solves the trouble of municipal moist waste disposal. The parameters discussed within the paper are temperature, pH, particle period, CN ratio; overall strong and unstable depend of the green waste slurry and working situations of biogas plant like organic loading waste, retention time, agitation, filtration and storage of biogas. The method proposed processing of the inexperienced waste through shredder mechanism via hopper, into bio digester, storage of biogas and filtration before utilization.

Keywords

Biogas, Green waste, Methane, Wet waste, Carbon neutral, Digester, Orset, Shredder.

Introduction

Nowadays growing community has led into technology of municipal stable waste on a big scale and has caused an ever increasing demand of energy. Waste era has brought about diverse troubles of pollution and is a motive of nuisance. Even after making use of the concept of four R’s which stands for reduce, reuse, recycle and renewable electricity, no right solution for disposal of municipal solid waste is accomplished. Dry and solid waste is processable the use of diverse strategies to recycle it. However moist waste consisting of kitchen and lawn waste is the location of foremost concern. Moist waste reason land pollution, leaching of leachate into floor water, scarcity of land due to era of landfills, breeding of rodents and bugs inflicting diseases and air pollutants. Improved populace has caused growth in call for cooking gas which led to inflation of fees. LPG on burning releases pattern amount of carbon dioxide as compared to methane. It possesses numerous risks whilst working with as being heavier has a tendency to sink [1]. Bio methane being renewable supply of power generated from moist waste provides sustainable development and easy gasoline that's green. Bio methane is the manner viable to solve this being carbon impartial i.e. it doesn’t add up carbon in atmosphere but recovers it.

Fruit and vegetable waste are organic fabric having the excessive calorific value and nutritive price to microbes, that’s why performance of methane production may be increased via numerous orders of magnitude. Its manner better performance and length of reactor and value of biogas manufacturing is reduced. Additionally, in maximum of cities and locations, fruit and vegetable waste are disposed in landfill or discarded which causes the general public fitness hazards and sicknesses like malaria, cholera, typhoid. Inadequate management of wastes like out of control dumping bears several detrimental consequences. It no longer most effective results in polluting surface and groundwater through leachate and similarly promotes the breeding of flies, mosquitoes, rats and other disorder bearing vectors. Additionally, it emits ugly odour and methane that's a main greenhouse gas contributing to global warming. Mankind can tackle this hassle efficiently with the assist of methane however until now we have no longer been benefited, due to lack of knowledge of basic sciences like output of labor is dependent on strength available for doing those paintings. This truth may be visible in modern day practices using low calorific inputs like farm animals’ dung, distillery effluent, Municipal Solid Waste (MSW) or sewage, in biogas plants, making methane era particularly inefficient. We are able to make this device extraordinarily efficient by using the use of kitchen waste or meals wastes. In 2003, Anand Karve (President ARTI) developed a compact biogas system that uses starchy or sugary feedstock material and the analysis shows that this new system is 700 times more efficient than conventional biogas plants. Bio methane is a clean burning, "green" fuel used for heating and cooking, transport and power generation. Biogas usually contains about 55%-65% methane, 30%-35% carbon dioxide and traces of hydrogen, nitrogen and other impurities. Its heating value is around 650 BTU per cubic foot (21 BTU per liter). Biogas can be used as a fuel in any country for any heating purpose, such as cooking, electricity and when compressed like natural gas can be used as vehicle fuel to power motor vehicles. Biogas is a renewable fuel, so it qualifies for sustainable energy subsidies in some parts of the world. Biogas can also be cleaned and upgraded to natural gas standards when it becomes bio methane.

Coker et al., was carried out a take a look at on the quantity and nature of meals wastes produced in a regular Yoruba household in Ibadan, Nigeria with the aid of with a population size of 7 to 8. Maximum of the meals processed and prepared within the family generate various quantities of waste, as much as 62%. If portions of meals waste are diverted from landfills it's going to offer a significant contribution toward attaining mandated solid waste diversion dreams. Further, diverting meals waste from landfills will prevent out of control emissions of its breakdown products, which include methane a strong greenhouse fuel [2]. Lactic Acid Bacteria (LAB) are chargeable for an exceptional diversification inside the taste and texture of meals merchandise due to their fermentation of meals raw materials. However, in a few situations they may be liable for food spoilage. Meals fermentation era, alongside drying and salting, is one of the maximum historic meals keeping techniques regarded to human beings. Fermented ingredients are much less perishable than the authentic uncooked materials, their dietary fee may be stronger and the protection of these foods may be stepped forward due to the inhibition of pathogenic bacteria through the low pH and the presence of organic acids and antimicrobial compounds.

Literature Review

Process of biogas production

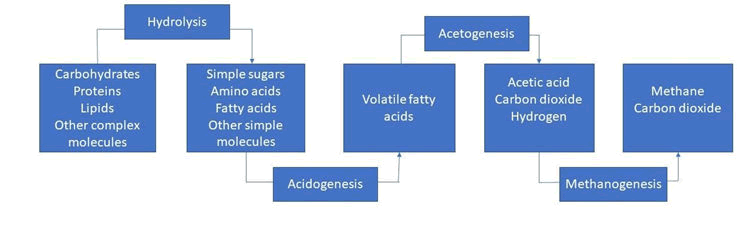

It is a simple process in which lactic acid bacteria break down complex organic matter into simple by products in absence of oxygen [3]. It is further subdivided into 4 steps as follows:

Hydrolysis: Being the prime step of anaerobic digestion involves breaking of macromolecules into micro molecules. It involves conversion of organic polymers into monomers using LAB bacteria. The macromolecules include polysaccharides, proteins and complex fatty acids which are converted into soluble sugars, amino acids and simpler fatty acids respectively. Carbohydrates are converted into sugars within few hours whereas proteins and lipids require few days to break down.

Acidogenesis: It involves formation of volatile fatty acids from substrate obtained from hydrolysis. It involves conversion of sugars, amino acids, fatty acids into short chain organic acids, alcohols, hydrogen etc.

Acetogenesis: It is fermentation system that includes conversion of unstable fatty acids into acetic acid, carbon dioxide and hydrogen with assist of precise organization of fermenting bacteria called as acetogenic and lactic acid bacteria.

Methanogenesis: That is the final level of anaerobic digestion where the primary byproduct methane is obtained. In this process microbe known as methanogens are liable for production of biomethane in suitable conditions. The stop products of acetogenesis are transformed into methane, carbon dioxide and hydrogen. pH stage between 5-8 and temperature between 30°C-60°C have to be maintained for higher rate of digestion. At the end of methanogenesis reduction between carbon dioxide and hydrogen takes area resulting in formation of 1-3 of total biomethane produced (Figure 1).

Bio methane is produced using a variety of procedures. Anaerobic digestion of domestic fruits, grass material, vegetable and fruit refuse and dairy waste water are all used in the production of biomethane. Lactic acid bacteria play a significant role in every activity. All steps include LAB, which generates bio methane. Various LAB species are employed in the creation of bio methane [4].

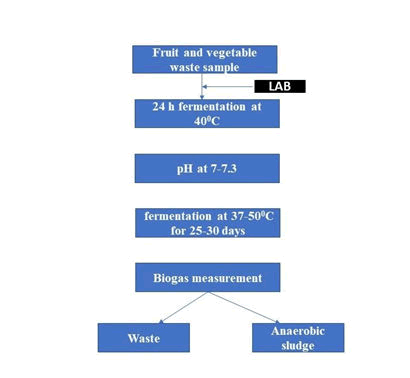

Methane was produced by LAB strains such as Lactiplanti bacillus plantarum AGR-1, L. plantarum AGR-2 and L. lactis sub sp. from new rye grass and rain treated dry grass. From dairy sewage water, Lactobacillus delbruecki spp. produced methane. From the refuse of fruits and vegetables, Lactobacillus casei and Lactobacillus acidophilus produced methane. In addition to producing bio methane, these procedures also lessen the pollution causing potential of refuse streams (Figure 2) [5].

Discussion

Factors affecting yield and production of biogas

Many factors affecting the fermentation process of organic substances under anaerobic condition are:

• The quantity and nature of organic matter

• The temperature

• Acidity and alkalinity (PH value) of substrate

• The flow and dilution of material

Bio methane production by using vegetable waste and fruit waste

Biomass, media components and inoculum instruction: Vegetable waste accrued from the neighborhood market and turned into used because the organic biomass for the fermentation lifestyle medium [6-8]. The freshly gathered vegetable waste changed into washed with ordinary tap water, then mixed with a domestic electric mixer to prepare the thick vegetable slurry and used within the experiments. Minimal buffer medium containing the 10 mm phosphate buffer containing the following salt components in a single liter:

• 0.034 g FeSO4

• 1.0 g CH3COONa

• 1.23 g MgSO4

• 7H2O, 0.034 g MnSO4

• H2O, 0.65 g 2HPO4

• 3H2O, 0.5 g KH2PO4

For developing seed tradition, 10 g of yeast extract and 2 g of tryptone were added to the above additives. The slurry changed into diluted as favored in keeping with the experimental design defined inside the consequences section. The changes if any were carried out consistent with the experiments and were specified within the respective consequences segment [9].

Fermentation with synthetic microbial consortia using vegetable waste and fruit waste

The vegetable slurry was combined with media to the final concentrations as cited above and the final media element concentrations had been kept regular for all experiments conducted in this have a look at [10]. The fermentation combination was prepared by way of blending vegetable slurry, distilled water (sterile), culture media (sterile) and inoculum. The seed inoculum of the mixed way of life turned into prepared by means of growing the subculture sand were pelleted, washed with saline (0.85% in D/W) and resuspended in a sterile lifestyle medium. This was used because the seed inoculum introduced to the fermentation blend [11,12]. The pH changed into adjusted to 6.0 or the preferred pH in line with the experimental design. Fermentation become conducted in 100 ml serum bottles containing 50 ml of tradition medium and sparged with N2 and sealed. The cultures had been grown at 35°C or temperatures according to the experimental design. The fermentation was performed at 120 rpm for 3 days or persisted in line with the experimental design (Figure 3) [13].

Conclusion

Biogas may be alternative supply for fueling choice. This guarantees right coping with and disposal of wet waste in towns. Dig estate acquired is notably rich in N:P ratio which will increase the growth of plant by means of more percentage as compared to chemical fertilizer. Kitchen waste has the first class desirable C/N ratio of 25:1 for biogas manufacturing. As per look at with the aid of incorporating the proposed parameters and substrate parameters might produce more biogas having better bio methane composition, this additionally will increase performance of biogas plant. Biogas also allows holding carbon neutrality. By applying all studied parameters biogas containing 75%-85% bio methane might be acquired. Biogas is a promising generation which offers sustainable fueling choice alongside financial benefits. In addition, look at on performance and price of biogas plant might really make it most low cost and clean to apply era leading in the direction of greener environment.

Acknowledgement

The author is sincerely thankful and highly indebted to the department of biotechnology and food testing laboratory, Junagadh Agricultural university for their valuable support and research facilities provided and all faculties, staffs and friends who were involved directly or indirectly in the successful accomplishment of the research. I express my deep sense of gratitude and indebtedness to Dr. Gira mankad, assistant professor, department of microbiology, MVM science and home science college, Rajkot, Gujarat, for giving me opportunity to carry out my project and for allowing me to do my project work under her supervision I acknowledge with appreciation the indispensable aid to Dr. Jalpa Maghodiya (Assistant professor at Noble university) for assistance and encouragement and also thankful Noble university Junagadh, Gujarat.

References

- Karlsson A, Bjorn A, Sepehr SY et al. Improvement of the Biogas Production Process: Explorative Project (EP1), Diva Portal, Sweden, 2014, 88.

- Akanksha A, Chaudhari PK, Ghosh P. Hydrolysis of the kitchen waste through dry anaerobic digestion-a sustainable environmental practice for its effective management, Europe PMC. 2021;15.

- Schnurer A, Jarvis A. Microbiological handbook for biogas plants, Scirp, Sweden, 2010, pp. 1-74.

- Rajendran K, Aslanzadeh S, Taherzadeh MJ. Household biogas digesters: A review, Agris Fao. 2012;5(8):2911-42.

- Santerre MT, Smith KR. Measures of appropriateness: The resource requirements of anaerobic digestion (biogas) systems, Agris Fao. 1982;10(3):239-61.

- Akinbami JF, Ilori MO, Oyebisi TO, et al. Biogas energy use in Nigeria: Current status, future prospects and policy implications, Ideas Repec. 2001;5(1):97-112.

- Singh KJ, Sooch SS. Comparative study of economics of different models of family size biogas plants for state of Punjab, India, Energy Conver Manag. 2004;45(9-10):1329-41.

- Cao Y, Takahashi T, Horiguchi KI, et al. Effect of adding lactic acid bacteria and molasses on fermentation quality and in vitro ruminal digestion of total mixed ration silage prepared with whole crop rice. Grassl Sci. 2010;56(1):19-25.

- Kim MS, Na JG, Lee MK, et al. More value from food waste: Lactic acid and biogas recovery. Water Res. 2016;96:208-16.

- Fabiszewska AU, Zielinska KJ, Wrobel B. Trends in designing microbial silage quality by biotechnological methods using lactic acid bacteria inoculants: A minireview. World J Microbiol Biotech. 2019;35:1-8.

[Google Scholar] [PubMed]

- Dreschke G, Probst M, Walter A, et al. Lactic acid and methane: Improved exploitation of biowaste potential. Bioresour Technol. 2015;176:47-55.

[Crossref] [Google Scholar] [PubMed]

- Menardo S, Balsari P, Tabacco E, et al. Effect of conservation time and the addition of lactic acid bacteria on the biogas and methane production of corn stalk silage. Bioenergy Res. 2015;8:1810-23.

- Fazzino F, Mauriello F, Paone E, et al. Integral valorization of orange peel waste through optimized ensiling: Lactic acid and bioethanol production. Chemosphere. 2021;271:129602.

[Crossref] [Google Scholar] [PubMed]