Research Article - Journal of Public Health and Nutrition (2022) Public Health and Nutrition Governance

Review on onion drying and effect of drying on nutritional content of onion processed products.

Biadge Kefale*

Department of Chemical and Food Engineering, Bahir Dar Institute of Technology, Bahir Dar University, Bahir Dar, Amhara, Ethiopia

- *Corresponding Author:

- Biadge Kefale

Department of Chemical and Food Engineering

Bahir Dar Institute of Technology

Bahir Dar University, Bahir Dar, Amhara, Ethiopia

E-mail: biadgekefale@yahoo.com

Received: 08-Jul-2022, Manuscript No. AAJPHN-22-68966; Editor assigned: 09-Jul-2022, PreQC No. AAJPHN-22-68966(PQ); Reviewed: 22-Jul-2022, QC No AAJPHN-22-68966; Revised: 25-Jul-2022, Manuscript No. AAJPHN-22-68966(R); Published: 29-Jul-2022, DOI:10.35841/aajphn-5.7.134

Citation: Kefale B. Review on onion drying and effect of drying on nutritional content of onion processed products. J Pub Health Nutri. 2022;5(7):134

Abstract

Onion is among the horticulture crops produced widely in the world. Due to its high water content it is perishable vegetable. To reduce the post-harvest loss of onion varies drying technologies used to process onion in to various forms such as flake, powder and paste. Drying technologies such as sundry, oven dry, spray dry, hot air dry, freeze dry, microwave drying and radio frequency drying are among the drying techniques. Freeze drying is the best technology that preserves nutritional and sensory quality of onion.

Keywords

Onion, Drying and commercial product.

Introduction

Onion production

Onions are the third most valuable vegetables in the world, following tomato. The production of onion crop is worldwide because of its wide benefits in our daily foods requirements. It is estimated that around the World, over 3,642,000 ha of onions are grown annually. On a worldwide scale, around 80 million metric tons of onions are produced per year. China is the top onion producing country in the world, accounting for approximately 28% of the world’s onion production, followed by India, USA, Iran, Egypt, Turkey, Russia, Pakistan, Netherlands and Brazil. The worldwide onion exports are estimated at around 7 million Metric tons. The Netherlands is the world’s largest onion exporter with a total of around 220,000 Metric tons followed at a distance by India. In Africa, Egypt is the leading country by producing 22.08 million tons of onion per year for domestic and international markets that rank as the fourth of world producer [1].

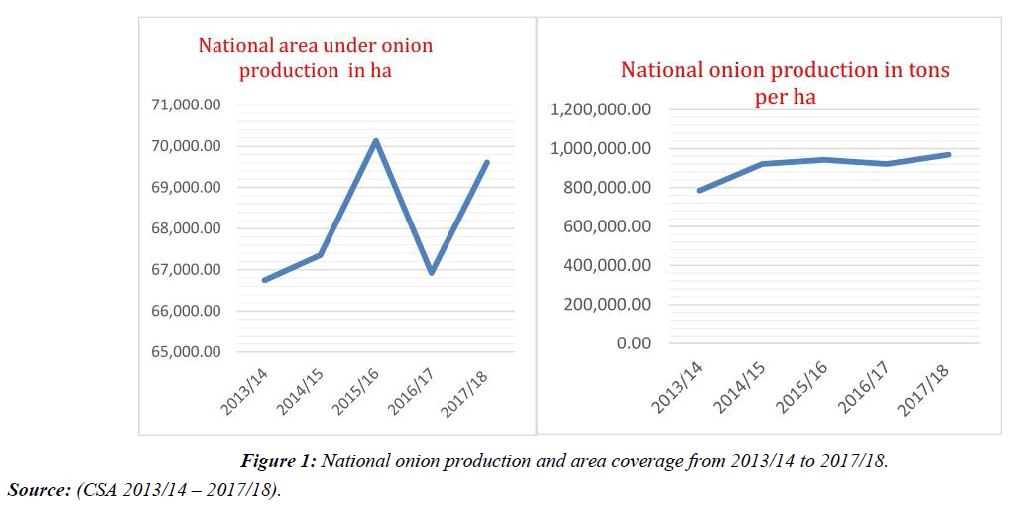

Onion was introduced to Ethiopia in the early 1970. Though shallots are traditional crop in Ethiopia, onions are becoming more widely grown in recent years. Currently, onion is one of the most important vegetable and spice crop in Ethiopia and mainly produced as a cash sources for the farmers. It ranked the second in production of all vegetable crops next to Tomato [2]. Onion is currently becoming a popular crop relatively despite to its recent introduction to the country because of its yield potential per unit areas, the ease of propagation method both by seed and bulb method, and the presence of high domestic and export markets and the area under onion production is an increasing rate from time to time mainly due to the merit of production and ease of marketing purposes. This crop can be cultivated twice per year both under the irrigation and rain feed conditions in different parts of the country. However, the production and productivity of the crop are far below (10.02 t/ha) the world average (19.7 t/ha) despite to its year round production scenarios (FAO 2012).

Nutritional content and health benefit

Onion (Allium cepa L.) belongs to the Alliacease family which is mostly used as a staple food due to the presence of essential oils that gain strong flavor and taste in diet. It has various forms as whole, raw, flakes, ground, liquid, dried or fermented for culinary uses. It has high effective nutrients as proteins, carbohydrates, sugars (glucose, fructose, galactose, arabinose), vitamins (C, β-carotenes), and minerals (calcium, iron, sulfur) with some flavonoids and polyphenols components. Onion is commonly used in many medicinal purposes as a traditional medicine for the treatment of skin diseases, microbial growth, gastrointestinal problems, worms and injuries and onion consumption can decrease the development risks for many diseases such as inflammatory, coronary heart, cancer and respiratory problems due to their bioactive components. Besides, the onion amino acids link with the sensory response of the “umami” taste. Onions contain huge amounts of arginine that acts as a nitrogen reservoir and quantity amounts of lysine and glutamic acids [3]. According to the USDA National Nutrient Database for Standard Reference (USDA, 2007), the nutritional composition of raw onions, per 100 g of edible portion is 89.11 g of water, 1.10 g of protein, 0.10 total lipids (fat), 0.35 g of ash, 9.34 g of carbohydrate, 4.24 g of total sugars and 1.7 g of total dietary fibre, corresponding to an energy of 40 kcal. Onion bulb can be red, yellow or white however; the taste does not depend on the colour. As a vegetable, it is a low in fat and calories, although, it primarily consumed for their ability to enhance the flavour of the other foods. It also contributes significantly to the human diet and has a therapeutic property.

It is a good source of vitamins, minerals, polyphenols and a number of phytonutrients. These phytonutrients such as phenolics and flavonoids present in onion have been found to act as antioxidants to lower blood pressure and prevent some kinds of cancer [4]. Onions are a good source of ascorbic acid and dietary fiber. It also possesses a high content of flavonoids (mainly quercetin and its conjugates) and sulpher compounds (thiosulphinates) both of which have a high level of antioxidant activity. Antioxidants can scavenge radicals by three major mechanisms: hydrogen atom transfer, electron transfer, and combination of both these transfers. High onion eaters have less cancer risk compared to no or low onion eater [5].

According to Bhadja (2015) study report in India about using red and white type local onion varieties. The findings revealed from all the variety studied, shows 58.14 to 77.67 % DPPH value, comparable amount of flavonoids (0.422 to 1.232 mg.g- 1) and anthocyanine content along with total phenol(8.96-18.23 mg.100 g-1), Pyruvic acid (1.09 to 1.33 mg.g-1), ascorbic acid (1.18 to 3.89 mg.100 g-1), protein (0.79 to 1.27%) and titrable acidity (0.34 0.75%) nutritional content.

Rodrigues [6] reported using two onion regional varieties (Allium cepa L.), Povoa white and Povoa red onions. From the Data showed that the red variety presents higher values for all the minerals and also protein, while white variety from Estela has the lowest dry matter content (13.15%) and fibre (0.83 g/100 g FW). Red variety shows higher concentration of glucose and fructose. The main flavonol quercetin 4’-glucoside, representing 55.3% in the red variety (35.43 mg/100 g FW) and 54.35% in the white (3.94 mg/100 g FW). Total anthocyanin content in red variety (5.37 mg/100 g FW) higher than for white variety (3.94 mg/100g fresh weight). Consequently, antioxidant activity higher for the red variety. For pungency, red variety can be classified as sweet (4.69 μmol Pyruvic acid/g FW) and white as very sweet (3.12 μmol Pyruvic acid/g FW).

According to Sami et al. (2021) (Table 1) study report the moisture content the main component of onion bulbs (88.65%) and rich in proteins (9.22–13.21 g/100 g in fresh weight) (FW). Results reported that Red and Yellow varieties established the largest vitamin C and carotenoids contents (45.07 mg/100 g-1 FW) and (1.44 μg/mL FW), respectively. The major amino acid arginine highly found in Green variety (17.02 mg/g FW) and a relatively high amount of glutamic and aspartic acids as (9.88-14.89 mg/g FW) and (4.93-10.55 mg/g FW), respectively. Yellow variety established the largest width, thickness, surface area, aspect ratio, and sphericity. According to Amoo and Ayoade. (2018) study report Onion (Allium cepa) examined for the proximate composition, mineral composition using standard methods. Proximate composition (%) of Allium Cepa; moisture (16.23), crude fat (2.96), crude fiber (5.90), ash (5.58), crude protein (12.53), carbohydrate (58.67) and dry matter (83.77) respectively. The mineral composition (mg/100 g) of the Allium cepa: sodium (40.67), calcium (289.69), potassium (90.25), magnesium (8.33), iron (2.65), zinc (1.78), copper (0.67), manganese (0.61) Figure 1.

| Nutrients | Nutrient Content | Samples used and country | Reference |

|---|---|---|---|

| 1.Moisture content | 88.76-91.94% | Seven variety, India | Bhadja. 2015 |

| 2. Fiber | 0.90-0.93% | Two variety, Portugal | Rodrigues et al. 2003 |

| 3.Protien | 12.53 % | Nigeria | Amoo and Ayoade. 2018 |

| 4. Ash | 9.34 % | America , USDA database | USDA, 2007 |

| 5. Vitamin C | 45.07 mg/100 g−1 | Saudi Arabia | Sami et al. 2021 |

| 6. Carotenoids contents | 1.44 µg/mL | Five variety, Saudi Arabia |

Sami et al. 2021 |

| 7. Pyruvic acid | 4.46-12.16 mg/L | Three variety, Ethiopia | Seifu et al. 2018 |

| 8.Sodium | 40.67 mg/L | Nigeria | Amoo and Ayoade. 2018 |

| 9. Calcium | 289.69 mg/L | ||

| 10. Potassium | 90.25 mg/L | ||

| 11. Magnesium | 8.33 mg/L | ||

| 12. Iron | 2.65 mg/L | ||

| 13. zinc | 1.78g/L |

Table 1. Nutritional content of onion bulb from different country.

Drying methods

Dried or dehydrated fruits and vegetables produced by different drying processes. Dehydration is the technique of removing moisture from solids. Many food products are dried to improve their shelf life by reducing the water activity and maintain the nutritional value of the fruit or vegetable (Table 2).

| Drying method | Effect on the physical-chemical, sensorial and nutritional properties of food | Recommended food |

|---|---|---|

| 1.Solar(sun)dry | Sun drying the product is heated directly by the sun's rays and moisture is removed by natural circulation of air due to density differences. | fruit, vegetables, meat and fish |

| 2.Hot air dry | Adversely affects the final quality of the product due to shrinkage, discoloration and loss of nutrients. problematic for thermally sensitive materials such as fruits and vegetables | Meat, fish |

| 3.Spray dry | Damages are limited and it can be used to treat heat sensitive material. | Milk, egg, juice, probiotics |

| 4.Freeze dry | used in industry for the dehydration of foods with high value and delicate aroma | mushrooms, herbs and spices, fruit juices, meats, seafood |

| 5. Infrared Drying | low thermal conductivity food | Solid food |

| 6. Microwave | high heating rate and does not originate alterations on the surface of the food and hence no crust is formed | Low moisture food |

| 7.Radiofrequency Drying | This novel drying method provides shorter time, higher energy efficiency and better product quality as compared to conventional hot air heating | fruit, vegetables, meat and fish |

| 8.Osmotic Dehydration | the principle that when cellular materials are immersed in a hypertonic aqueous solution, a driving force for water removal sets up because of the higher osmotic pressure of the hypertonic solution | Fruit and vegetable |

Table 2. Drying methods and the effect of drying on the physical-chemical, sensorial and nutritional properties of food

Predrying treatments: Predrying treatments prepare the raw fruits and vegetables for the dehydration process, and include raw product preparation and colour preservation. The colour preservation method differs for fruits and vegetables, with most fruits using Sulfur Dioxide (SO2) gas and most vegetables using sulfite solutions.

Drying or dehydration: The main objective of any drying process is to produce a dried product of desired quality at a minimum cost and maximum throughput and to optimize these factors consistently [7]. Different drying methods are available for drying of the agricultural crops.

Oven drying: The oven drying method is quicker (between 6 and 24 hours). For oven drying the vegetables are put on the oven trays or better oven grids, and the oven is preheated. It is possible to put more than one tray into the oven at once but then the trays need to be 5 to 8 cm apart from each other and also from the top and the bottom of the oven. During drying open the oven door a little bit to allow moisture to go out. In addition, a fan put in front of the oven door can be used to increase ventilation and thereby reduce drying time. Special care has to be taken that the vegetables do not get burned in the oven.

Solar drying: Drying is the oldest preservation technique of agricultural products and sun drying is still widely used for preservation of agricultural products in the tropics and subtropics. Solar dryers can be classified into two broad categories: passive and active solar dryer. In direct solar drying called ``sun drying'' the product is heated directly by the sun's rays and moisture is removed by natural circulation of air due to density differences [8]. Solar radiation in the form of solar thermal energy is an alternative source of energy for drying especially to dry fruits, vegetables, agricultural grains. It is estimated that in developing countries there exist significant postharvest losses of agricultural products, due to lack of other preservation means [9]. Drying by solar energy is a rather economical procedure for agricultural products, especially for medium to small amounts of products. It is still used from domestic up to small commercial size drying of crops, agricultural products and foodstuff, such as fruits, vegetables, aromatic herbs, wood contributing thus significantly to the economy of small agricultural communities and farms [10]. Solar dryers classified as natural convection solar dryers and forced convection solar dryers. In the natural convection solar dryers, the airflow is usually established by buoyancy induced airflow while in forced convection solar dryers, the airflow is provided by using fan either operated by electricity/solar module or fossil fuel [11].

Hot air drying: Conventional drying (hot air) offers dehydrated products that can have an extended life of a year. But the quality of a conventionally dried product is drastically reduced from that of the original foodstuff [12]. The methods in which hot air is used for drying foods are very versatile and have a considerable importance. These include drying in chambers with trays or in tunnels equipped with conveyor belts in rotating drum driers or even in fluidized bed driers [13].

Spray drying: Spray drying is a widely used technique to convert a liquid state into a powder form. It is used for solutions or slurries that go through an atomizer or spray in order to divide the material into droplets (10-200 micrometer). The quality of spray dried microcapsules is quite dependent on processing parameters of the spray dryer and properties or composition of the feed solution [14]. Given the reduced dimensions, the drying time is short (1–20 s) so damages are limited and it can be used to treat heat sensitive materials. Spray drying is the most common microencapsulation process and has proven to be an effective technology in protecting bioactive compounds and probiotics. It consists in converting water suspensions into powdered microparticles, which are composed of a wall material (shell) and a core (encapsulated material) [15].

Freeze drying (Lyophilization): Freeze drying is based on the dehydration by sublimation of a frozen product. Due to the absence of liquid water and the low temperatures required for the process, most of deterioration and microbiological reactions are stopped which gives a final product of excellent quality [12]. Freeze drying or freeze dehydration, the water is first frozen and then sublimated, under special conditions of pressure and temperature [13]. Lyophilization is used in industry for the dehydration of foods with high value and delicate aroma and (for example: mushrooms, herbs and spices, fruit juices, meats, seafood or complete diets for military use or sport expeditions), as well as for the preservation of microbial cultures used in the food industry. Lyophilization is usually preferred to convert heat sensitive materials into powder form because is better at preserving their native conformations. However, long processing times, low production throughput, batch mode of production and possible chill injury associated with freezing are considerable disadvantages of this process.

Infrared drying: In infrared drying, the solid food is exposed to a source of infrared heating increasing the temperature of its surface. Because most of the solids have a low thermal conductivity, the rate of heat conduction to the interior is very slow. Hence, the application of infrared radiation primarily intends the surface treatment of foods. Infrared radiation energy is transferred from the heating element to the product, heating the material more rapidly and uniformly without heating the surrounding air, and hence the energy is used in a more efficient way. The irradiated surface evaporates much more water and drying time is shortened by up to half. Combined with hot air pre drying, infrared heating can save 20% of drying time compared with the infrared drying alone [16].

Microwave drying: This method provides a high heating rate and does not originate alterations on the surface of the food and hence no crust is formed. The industrial microwave treatment is limited due to its high cost and to the need to synchronize the generator for different foods. Thus, it is used industrially for low moisture foods, or as a final stage of the dehydration process. Microwave drying is an efficient method for postharvest processing of agricultural products due to time efficiency, low energy consumption and high product quality, which are major factors to be considered by the industry. With the development of new technologies, more parameters can be monitored and controlled during the drying process, such as temperature, weight, power or odour [17]. Compared to convective drying, microwave drying can be advantageous due to its volumetric heating and reduced processing time. On the other hand, it may cause overheating of particles and undesired degradation of bioactive compounds, but the use of microwaves under vacuum may significantly prevent from quality degradation of heat sensitive materials. But it is important to notice that the use of microwaves under reduced pressure increases the drying costs, which could however be minimized by combining the two drying processes: microwave vacuum with convection [18].

Radiofrequency drying: The use of radiofrequency energy for dielectric heating of food materials is an important application area, which has been studied as a possible method for drying agricultural products. The radiofrequency heating addresses directly the product, so that its interior is heated faster than its surface. The water is released without overheating or dehydration of the surface. Therefore, it can be used as a complement to other drying processes, and allows reaching very low humidity levels, of the order of 1 to 2%, with minimal impact on quality. This novel drying method provides shorter time, higher energy efficiency and better product quality as compared to conventional hot air heating [19].

Osmotic dehydration: Osmotic dehydration is based on the principle that when cellular materials are immersed in a hypertonic aqueous solution, a driving force for water removal sets up because of the higher osmotic pressure of the hypertonic solution. It is generally used for partial removal of water from fruits or vegetables which are immersed in a sugar or salt solution (which has an osmotic pressure higher than the food). Typically it requires 4-6 h to reduce the food to 50% of its fresh weight, and that is why it is used industrially as a pretreatment for other operations. So, it is necessary to complement the process using other preservation techniques, such as: microwave assisted air drying, ultrasound assisted osmotic dehydration and air drying, osmotic dehydration with moderate electric field and vacuum air drying, blanching and vacuum pulse, ohmic heating and vacuum impregnation, among others (da Costa Ribeiro, Aguiar-Oliveira, and Maldonado 2016)For fruits the hypertonic solution are used sugar solutions (40-70%), being the most commonly used sugar sucrose, but fructose, glucose or mixtures of glucose / fructose and glucose / polysaccharides are also used. For vegetables are used salt solutions (5-20%), normally sodium chloride [20].

Combined processes: There are many conventional drying methods used in post-harvest technology including solar drying, osmotic dehydration, vacuum drying, hot-air drying, fluidized bed drying, and freeze drying. However, most of these drying techniques involve longer drying time and high amount of energy, resulting in poor quality of the dried products. It has been suggested a new way of improving the existing conventional drying processes based on self-heat recuperation technology. However this method, which focuses mainly on increasing the energy efficiency of the drying process, is complex and expensive to adapt. There have been significant developments in using novel techniques, like microwave, radio frequency, infrared, pulse electric field, ultraviolet, ultrasound, ohmic, supercritical, and heat pump heating, in the drying of agricultural crops in terms of pre- treatment, techniques and equipment design that allow increasing process efficiency and enhance the quality of the final dried products [21]. Some typical combined drying processes include: convection & microwaves, convection & osmotic dehydration, convection & infrared radiation, convection & ultraviolet radiation, convection & vacuum, convection & ultrasound, spray drying & lyophilization, lyophilization & ultrasound, lyophilization & infrared radiation, among many other possible combinations.

Effect of drying on nutritional content of onion

Arslan and Ozcan [8] reported using Sun, oven (50 and 70 °C) and microwave oven (210 and 700 W) drying of onion slices used to monitor the quality degradation of the product. Fresh and dried onion slices had high amounts of K (696.82 mg/kg), Ca (69.64 mg/kg), Na (37.72 mg/kg), Mg (3.31 mg/ kg) and P (46.47 mg/kg) minerals. The highest mineral values determined in oven dried samples. Sun (L* 58.00, a* 0.27, b* 14.36) and microwave oven drying (210 W) (L* 54.78, a* 0.71, b* 13.17) revealed better colour values in the dried products. The phenolic contents of microwave oven dried samples (1664.39 and 1623.59 for 210 Wand 700. Soysal (2004) reported that although the microwave drying resulted in some darkening of the parsley leaf colour, compared to the fresh herb a* values of fresh and microwave dried (210 W) samples had lower than the values of other dried samples which showed a greener colour. Microwave oven (700 W) and oven (70°C) dried samples had the highest a* values which means higher redness in colour of these samples.

Sigui and Bamba [22] reported the effects of temperature (70, 80, and 90°C), time (2, 4, 6, and 8 hr), and blanching (100 °C for 5 min) followed by drying at 70°C for 8 hr on the physicochemical (Ash, pH, and titratable acidity), and functional (water solubility index and particle size) properties of onion powder, as well as compared to local market powders. The powder showed a small particle size (under 400 μm) and high solubility (81.36 g/ below 13 g/100 g with pH under 4. Drying at 80°C for 8 hr without blanching emerge as the best compromise drying conditions resulting in optimal physico-chemical and functional properties (10.8 g/100 g, 846.6 mg GAE/100 g DM and 88.12 g/100 g DM of moisture content, total polyphenol content and water solubility index, respectively.

According to Mota et al. [23] study report of the drying of onions at 30°C, 50°C and 60°C. The chemical characterization in fresh and dried onions at different temperatures (varying from 30°C to 70°C) analyzed, to evaluate the effect of drying and drying temperature on the chemical composition of the product. From the results obtained some chemical components of the onions are not affected by drying (ash, fat, protein and fiber) whereas some others are considerably influenced by drying (sugars, acidity and vitamin C).

Girma Masresha [24] reported the drying characteristics of Adama red onion (Allium cepa) in an oven and fluidized bed dryer after treating the onion slice in osmotic solution. The osmotically dehydrated onion slices then dried in a fluidized bed dryer and conventional oven at drying air temperatures of 50 °C, 60 °C, and 70 °C. The quality parameters, such as rehydration ratio, ascorbic acid, microbiological quality and sensory quality (color, appearance, and overall acceptability) of the dehydrated onion determined. The highest number of acceptable quality parameters reported for osmotic fluidized bed dried samples at 50°C. According to Demissew and Temesgen [25] study report the nutritional and volatile components of different drying methods of onion evaluated. Effect of different drying method on protein, carbohydrate, total sugar, fat, pyurvic acid, ascorbic acid, total phenol, total flovonol, rehydration ratio, colour and sensory properties of onion slice evaluated and found insignificant at (P<0.05) for microwave and modified direct solar dryer. But oven drying method had significant effect on onion bulb quality attributes at (P<0.05) than other two drying methods. The proximate composition of onion slice is (dry weight basis) similar with finding and report at drying temperature of 35°C.

Olalusi [26] reported the drying characteristics of red and white varieties of onion (Allium cepa) in a convective dryer. The drying characteristics of onion slices examined at air temperatures of 50°C, 60°C and 70°C and sample thicknesses of 2 mm. During the drying experiments, air velocity held stable at 0.9 m/s. The effects of air temperature on the drying characteristics and quality parameters such as vitamins C and D, macro minerals (Mg, Na, P, Ca and K), non-enzymatic browning and thiosulphinates of the dried onion slices observed [27]. The time required to reduce the moisture content to any given value dependent on the drying conditions, being the longest at an air temperature of 50°C, 0.9 m/s and the shortest at an air temperature of 70 °C and air velocity of 0.9 m/s. The loss of vitamin C, which is a thermo sensitive compound, was the least at an air temperature of 50°C.

According to Seifu et al. [28] study report the effects of variety (Bombay red, Qellafo and Sweet carolin) and drying temperature (Fresh, 50, 60, 70, 80, and 70°C) on physicochemical quality, functional property, and sensory acceptability of dried onion powder determined. The results indicated that total colour change of Bombay red was not affected by temperature, but Qellafo and Sweet carolin varieties showed an increase in colour change as drying temperature increases. Bulk density, shrinkage ratio, and water hydration capacity increased with increasing temperature for all three varieties. The degradation of vitamin C, pyruvic acid, and desired sensory attributes increased with increasing oven drying temperature. Qellafo dried at 70 °C for 5 hrs found to be desirable for production of dehydrated onion powder.

Gabel [29] reported Onions dehydrated using a catalytic flameless gas fired infrared (CFGIR) drier had a significantly higher drying rate at 70C when compared to the forced air convection (FAC) drier. Samples dried at 60°C showed no significant difference between the different drying methods. No major differences in quality attributes, namely pungency and colour found in samples dehydrated by each drying method. Onions dried in the FCGIR drier resulted in better color compared to retail samples of onions powder and minced onions.

According to Guiné et al. [30] study report the textural properties of onion, fresh and after freeze drying showed. The fresh product had average moisture content of 90.02 % and the freeze dried onion had a moisture content of 5.19 %. The hardness of the onions decreased from the fresh to the dried state. A similar behaviour observed for the chewiness, which also decreased, but in a much less extent. On the other hand, cohesiveness increased slightly with drying (Table 3).

| Reference | Drying method | Effect of drying on nutritional and sensory attributes |

|---|---|---|

| Arslan and Özcan .2010 | Sun, oven(50 ,60,70 °C), Microwave oven(210 and 700W) |

Colour of dry onion is better in Microwave oven and mineral content of dry onion is better in oven |

| Sigui and Bamba.2020 | Oven dry (70,80,90 °C) | Drying at 80 °C compromise drying condition result in optimal physic chemical and functional property(MC, Polyphenols, water solubility index) |

| Mota et al. 2009 | Oven(30,50,60,70 °C) | Sugars, vitamin C and acidity influenced |

| Girma et al., 2015 | Oven(50,60,70 °C),osmotic fluidized bed dryer | At 50 °C for osmotic fluidized bed drying highest acceptable quality parameter reported. |

| Demissew and Temesgen. 2018 | Microwave, solar ,oven dry | Oven dry affect significantly for bulb quality attribute |

| Olalusi. 2014 | Convective drying | At 50 °C loss of Vitamin C reported |

| Seifu et al. (2018) Gabel. 2004 | Oven dry(50,60,70,80 °C) Infrared Drying(60,70°C) | Degradation of vitamin C ,purvic acid and sensory attributes reported at high Temperature At 60 °C the best quality attribute of dried onion reported |

| Guiné et al. 2016 | Freeze dry | MC decrease from 90 to 5% and hardness and chewiness decreased while cohesiveness increased |

Table.3 Influence of drying method on physico-chemical, nutritional and sensory attributes of onion

Processed products of onion

There is a general increase in demand for processed onions because of the high perishability of fresh onion. Onion is one of the most consumed vegetables in the world, as result the demand across the world is a steady increasing [31]. To satisfy this demand several types of natural onion products are currently available to food processors. These include dehydrated onion in powder or pieces such as onion juice concentrated to a viscous syrup or thick paste and also offered in dry form as dispersion on salt or dextrose.

Dehydrated onion pieces (Flakes): In order to prolong the shelf life of the postharvest onion bulb product, employing preservation and processing technologies are necessary. Cured or dried onion has 4 to 5% moisture to allow good storage and acceptable quality. The product is processed to make powder, granules, flakes or slices, then used for the formulation of sausages, meat products, many kinds of soups and sauces as well as dressings [32].

Onion powder: Onion powder is a spice made from dried onions that retains some of the pungency and flavor of fresh ones. Some cooks like to use the powder because it is easier to handle than fresh onions, requiring no chopping or special treatment, and a number of recipes call for it. Most markets carry this spice, typically with the other dried spices, and there are several varieties available in many places. Onion powder is prepared either from dehydrated onion pieces or from puree. A stronger flavoured product is obtained by spray drying. The powder is a uniform product of which 95% passes a sieve of 0.25 mm aperture size. This is the finest among onion products including grifts, flakes, slices and rings, and used for soups, relishes, sauces, and products that do not require onion appearance and texture. Discoloration develops during the processing of onion.

Onion oil: Onion oil is obtained by distillation of minced onion. Most onion oil components are generated enzymatically from their precursors such as S-1-propenylcysteine sulfoxide, S- 1-propylcysteine sulfoxide and S-methylcysteine sulfoxide. The minced onion is allowed to stand at ambient temperature for a few hours prior to distillation to complete the enzymatic and successive chemical reactions. The onion oil can be obtained in 0.002 to 0.03% yields as a brown-amber liquid, and collected from the bottom of a vessel placed under a steam condenser.

Pickled onion: Onion may be preserved in vinegar as pickled products. A translucent product with a desired texture is preferable. Usually, onion is soaked in 10% saline solution for 24 h, is transferred to a bottle, and spiced vinegar is added [33].

Onion paste: The onion is an important vegetable and Onion Paste is pungent, aromatic and imparts fiery hot taste to food which generates treat for tongues and leaves you with memorable eating experience. It can be made with either boiled or fried onions and can be instantly used for quick preparation of gravy, as base for many curry preparations and for flavoring. These products are low in fat and cholesterol and are uniquely processed to maintain the fresh aroma and taste. Further, we also ensure that these are processed under proper hygienic conditions to avoid any sort of adulterations (Deltasupplies.co.in. 2014).

Conclusion

The production of onion crop is worldwide because of its wide benefits in our daily foods requirements. It has various forms as whole, raw, flakes, ground, liquid, dried or fermented for culinary uses. It has high effective nutrients as proteins, carbohydrates, sugars (glucose, fructose, galactose, arabinose), vitamins (C, β-carotenes), and minerals (calcium, iron, sulfur) with some flavonoids and polyphenols components. Dried or dehydrated fruits and vegetables produced by different drying processes. Dehydration is the technique of removing moisture from solids. Many food products are dried to improve their shelf life by reducing the water activity and maintain the nutritional value of the fruit or vegetable.

References

- Limeneh DF. Review on production status of onion seed yield, nutrient uptake and use efficiency of nitrogen and phosphorus fertilizations in Ethiopia. 2021;9(5):366-77.

- Etana MB. Major Onion (Allium Cepa L.) Production Challenges in Ethiopia: A Review. J Biol Agric Healthc. 2019;9(7):1-6.

- Rokayya S, Elhakem A, Alharbi M, et al. Nutritional Values of Onion Bulbs with Some Essential Structural Parameters for Packaging Process. Appl Sci. 2021;11(5):2317.

- Bhadja NV, Kandoliya UK, Bajaniya VK. Determination of Nutritional Value and Antioxidant from Bulbs of Different Onion (Allium Cepa) Variety : A Comparative Study. Int J Curr Microbiol App Sci. 2015;4(1):635-41.

- Health and Nutrition overview. 2019.

- Rodrigues AS, Fogliano V, Graziani G, et al. Nutritional Value of Onion Regional Varieties in Northwest Portugal. 2003.

- Chua KJ, Mujumdar AS, Hawlader MNA, et al. Batch Drying of Banana Pieces - Effect of Stepwise Change in Drying Air Temperature on Drying Kinetics and Product Colour. Food Res Int. 2001;34(8):721-31.

- Arslan D, Ozcan MM. Study the Effect of Sun, Oven and Microwave Drying on Quality of Onion Slices. LWT. 2010;43(7):1121-27.

- Bateno T, Buke T. Postharvest Losses and Management Assessment of Commercial Fruit and Vegetable at Wolaitazone, at Sodo Market. Int J of Res Innov Earth Sci. 2018;5(3):99-105.

- Mujumdar A. Handbook of Industrial Drying, Third Edition. 2006.

- Janjai S, Bala BK. Solar Drying Technology. Food Eng Rev. 2012;4(1):16-54.

- Ratti C. Hot Air and Freeze-Drying of High-Value Foods: A Review. J Food Eng. 2001;49 (4):311-19.

- Guine RPF. The drying of foods and its effect on the physical-chemical, sensorial and nutritional properties. 2018;4(2):93-100.

- Wang T, Hu Q, Zhou M, et al. Preparation of Ultra-Fine Powders from Polysaccharide-Coated Solid Lipid Nanoparticles and Nanostructured Lipid Carriers by Innovative Nano Spray Drying Technology. Int J Pharm. 2016;511(1):219-22.

- Arpagaus C. Production of Food Bioactive-Loaded Nanoparticles by Nano Spray Drying. Nanoencapsulation of Food Ingredients by Specialized Equipment. 2019;3:151-211.

- Adak N, Heybeli N, Ertekin C. Infrared Drying of Strawberry. Food Chem. 2017;219:109-16.

- Pu H, Li Z, Hui J, et al. Effect of Relative Humidity on Microwave Drying of Carrot. J Food Eng. 2016;190:167-75.

- Magdalena Z, Michalska A. Microwave-Assisted Drying of Blueberry (Vaccinium Corymbosum L.) Fruits: Drying Kinetics, Polyphenols, Anthocyanins, Antioxidant Capacity, Colour and Texture. Food Chem. 2016;212: 671-80.

- Alan KS, Wang L, Schmidt K. Heat Stability of Radio Frequency Dielectric Heat Treated Low Heat and High Heat Nonfat Dry Milk. Int Dairy J. 2017;74:21-6.

- Amami E, Wissal K, Mezrigui S, et al. Effect of Ultrasound-Assisted Osmotic Dehydration Pretreatment on the Convective Drying of Strawberry. Ultrason Sonochem. 2017;36:286-300.

- Oladejo AO, Ma H, Qu W, et al. Effects of Ultrasound Pretreatments on the Kinetics of Moisture Loss and Oil Uptake during Deep Fat Frying of Sweet Potato (Ipomea Batatas). Innov Food Sci Emerg Technol. 2017;43:7-17.

- Sigui B, Bruno B. Effects of Onion Bulb Processing Conditions on Drying Characteristics, Physicochemical and Functional Properties Profile of Onion (Allium Cepa L.) Powder. J Food Sci. 2020;85(10):3345-54.

- Mota CL, Luciano C, Dias A, et al. Convective Drying of Onion : Kinetics and Nutritional Evaluation. Food Bioprod Process. 2010;88(2-3):115-23.

- Masresha G. Addis Ababa Institute of Technology ( AAiT ) School of Chemical and Bio Engineering Effect of Process Conditions on Osmotic Dehydration of Adama Red Onion Slice Production Addis Ababa Institute of Technology ( AAiT ) School Of Graduates Studies School. 2015.

- Demissew A, Meresa A, Temesgen K. Evaluation of Drying Methods on Some Nutritional and Volatile Components of Bombay Red Onion (Allium Cepal L). Preprints. 2018;2018030101.

- Ayoola O. Hot Air Drying and Quality of Red and White Varieties of Onion (Allium Cepa). J Agric Food Chem. 2014;3(4B):13-9.

- Gouda GP, Ramachandra CT, Nidoni U, et al. Studies on drying characteristics of onion (variety-Arka kalyan) slices using different drying methods. J pharmacogn phytochem 2018;7(2):1013-6.

- Muhaba S, Tola YB, Mohammed A, et al. Effect of Variety and Drying Temperature on Physicochemical Quality, Functional Property, and Sensory Acceptability of Dried Onion Powder. Food Sci Nutr. 2018;6(6):1641-9.

- Gabel M, Pan Z, Amaratunga S. Quality and safety characteristics of infrared dried onion products. Am soc agric biol eng. 2004.

- Pinho R, Guin F, Jo M. Texture of Onions before and after Freeze- Drying. 2016.

- Pooja BK, Jagadeesh SL, Prashanth SJ, et al. Effect of Different Pre-Treating Chemicals on Physico-Chemial Qualities of Onion Dried Using Solar Tunnel Dryer. J Pharmacogn Phytochem. 2018;7(4):1940-43.

- Kumar DGP, Umesh Hebbar HU, Sukumar D, et al. Infrared and Hot-Air Drying of Onions. J Food Process Preserv. 2005;29(2):132-50.

- Kaack K. Industrial Processing of Pickled and Pasteurized Onion (Allium Cepa L.). Int J Fores Hort. 2017;3(2):35-45.

Indexed at, Google scholar, Cross ref

Indexed at, Google scholar, Cross ref

Indexed at, Google scholar, Cross ref

Indexed at, Google scholar, Cross ref

Indexed at, Google scholar, Cross ref

Indexed at, Google scholar, Cross ref