Research Article - Journal of Biochemistry and Biotechnology (2021) Volume 4, Issue 2

Determining the potential of both pure anaerobic sludge and anaerobic sludge mixed with Eucalyptus' ashes as fertilizers.

Saidelamine Abibe Mahadal1*, Gino Roberto Gehling2, António Comando Suluda3, Momade Sefu4

1Department of Engineering and Technological Sciences, Rovuma University, Napipine Campus, Nampula, Mozambique

2Department of Hydraulic Research Institute, Federal University of Rio Grande do Sul (UFRGS)-IPH, Porto Alegre, Brasil

3Department of Mathematics and Natural Sciences, Licungo University, Beira Branch, Mozambique

4Department of Mathematics and Natural Sciences, Rovuma University, Napipine Campus, Nampula, Mozambique

- Corresponding Author:

- Saidelamine Abibe Mahadal

Department of Engineering and Technological Sciences

Rovuma University, Napipine Campus

Nampula, Mozambique

E-mail: smahadal@gmail.com

Accepted date: February 19, 2021

Citation: Mahadal SA, Gehling GR, Suluda AC, Sefu M. Determining the potential of both pure anaerobic sludge and anaerobic sludge mixed with Eucalyptus’ ashes as fertilizers. J Biochem Biotech. 2021;4(2):1-10.

Abstract

The generation of urban and industrial solid residues fit for recycling and reuse, calls for studies into the best ways to their reutilization. In this study, the potential use of both anaerobic pure sludge and anaerobic sludge mixed with Eucalyptus’ ashes as fertilizers was determined through mixing the of residues in the ratios of 30, 50 and 100 percent ashes in relation to the weight of dry sludge. Samples were collected and sent to the laboratory for analysis. The parameters that determine agronomical potential such as pH, humidity, volatile/total solids ratio, total organic carbon, sulphur, phosphorus, amonyacal nitrogen, total Kjeldahl nitrogen, potassium, magnesium and lime, were analysed. The vegetable biomass ashes from VERACEL Company contain accentuated alkalyne content. The mixing of anaerobic sludge and ashes is an advantageous process because the later contributed with potassium, lime and magnesium and the sludge provided nitrogen, and phosphorus, generating biosolids with the necessary nutrients for agricultural soil fertilization.

Keywords

Sludge, Ashes, Biosolids, Fertilizer.

Introduction

The quantity of sewage sludge grows with the increase in collection and sewage treatment services [1]. It is necessary to conduct studies, in various countries, on the application of biosolids on forest soils, thus proving the conditioning and fertilizing capacity of these residues, according to the soil and climate of North America, Europe, Asia and Africa [2,3].

The growing cellulose and paper production result in large quantities of residues which are both an environmental and economical problem for the industry. In this scenario, residues’ reutilization options have to be considered and analyzed in order minimize their impact. Of all the being generated residues, ashes deserve a special mention because their agricultural use may be a viable alternative for the discarding besides reducing the agriculture and forestry production costs [4].

Forest biomass ashes are referred as a fertilizer due to their high cathion content, [5] as well as their acidity corrector ability, Ca, Mg and K source [6]. The ashes’ acidity neutralization capacity depends on the quantity of oxides, hydroxides and Ca, Mg and K carbonates in them [7].

According to [8], forest ashes are deficient in nitrogen and the elements contained in them are Fe, Zn, Ni, Cr, Pb, Hg, Cu, B, Mo, V, Ba, Cd and Ag. The use of forest ashes is desirable from the ecological point of view as it increases the nutritional status of reforestations [9].

The main concern in relation to the use of forest’s biomass ashes is the concentration of potentially toxic elements, like heavy metals which may lead to the increase in their concentration in the soil. However, the application of forest ashes does not cause meaningful increase of metals’ concentration in the soils [3,10].

The properties of forest ashes depend on many factors such as: type of plant, part of plant used (bark, trunk, leaves) and the combustion conditions. A key factor in the final composition of the ashes is the firing temperature and if the boiler separates the fly ash from the bottom ash. Temperatures between 500°C and 900°C are crucial for the retention of nutrients, specially potassium (K). Potassium (K), sodium (Na) and zinc (Zn) contents and carbonates diminish with temperature hike, probably due to the low boiling and decomposition point of these materials, while the other materials’ content either remains constant or increases [11].

The generated residues need to be adequately disposed of or be applied on agricultural or forest areas.

Materials and Methods

Ashes and sludge samples’ source

The ashes mixed with sludge to obtain the biosolids resulted from burnt Eucalyptus in the paper and cellulose production process at VERACEL Company located in the southern region of Bahia. The company uses the Kraft method in the cellulose production process because it is the most efficient and, consequently, the most used in the industry. The sludge under analysis is the digested anaerobic, from Serraria Treatment Facility located in the southern region of Porto Alegre.

Sampling and sample preservation

The sludge samples were collected each 15 days, as advised by the CONAMA resolution 375/2006. Table 1 displays the dates the four raw samples were collected. The samples were kept in plastic containers that were, in turn, kept in ice inside Styrofoam boxes during transportation to the laboratory.

| Collection date | Sample | Processing | Analysis dates | |

|---|---|---|---|---|

| Raw | Processed | |||

| 07-12-2017 | S1 | S1-W, S1-30 and S1-50 | 07-12-2017 | 9/21/2017 |

| 07-26-2017 | S2 | S2-W1, S2-30 and S2-50 | 07-26-2017 | 10/18/2017 |

| 08-09-2017 | S3 | S3-W, S3-30, S3-50 and S3-100 | 08-09-2017 | 11/21/2017 |

| 08-30-2017 | S4 | S4-W, S4-30, S4-50 and S4-100 | 08-30-2017 | 11/21/2017 |

Samples’ nomenclature: The first digit of the sample refers to the batch; the second to the percentage of ashes in relation to the solid sludge content; W stands for control.

Table 1: Sample’s collection processing calendar.

Experimental protocol

The experimental protocol consisted of the collection of the samples at ETE Serraria and their immediate forwarding to certified laboratories for the planned analysis.

The sludge processing consisted of its mixing with ashes in the proportions of 30%, 50% and 100%, in triplicate. For the proportion of 30%, 3000 g of sludge were mixed with 180 g of ashes; for 50%, 3.000 g of sludge were mixed with 300 g of ashes. And for the 100% proportion, 3000 g of sludge were mixed with 600 g of ashes. The processing was done in small quantities, in bench processing, making it easy to do manually. The mixture was made homogenous, samples were quartered and kept, after processing, in open plastic trays which were tagged and kept outdoors for 60 days. During rainy days all was covered by a plastic canvas.

After the 60 day incubation period, the samples were sent to Bioensaios and Porto Belo laboratories for the analysis of the parameters mentioned earlier. Table 1 shows the collection calendar and the days the raw and treated samples were sent to the laboratories for analysis.

The raw anaerobic sludge presented a neutral pH, (7.1). During the mixing process of sludge with ashes in order to stabilize it, the sludge/alkalinizer mixture’s pH increased; after some time, during the stabilization process, a drop in the mixture’s pH was noticed. To avoid an excessive drop in the pH value during the first 2 hours after mixing the sludge with ashes, a pH value higher than 12 is needed and this occurs when the alkalinizing element’s concentration is increased. The dose of the alkalinizing substance, for the boost of the pH depends on many factors, such as the type of sludge (primary, activated sludge, etc.), its chemical compositions and the concentration of solids in the sludge.

Lab analyses

The chemical composition of the ash samples was analysed using the methodologies listed in Table 2.

| Determination | Methodology | Detection limit |

|---|---|---|

| Humidity, CRA | Gravimetry | - |

| pH | Potenciometry 1:5 | - |

| Organic carbon | Humid combustion | 0,01% |

| NTK | Kjeldahl | 0,01% |

| CTC | Normative instruction MAP 28/2007 | 0,1 cmol/kg |

| Electric conductivity | Conductometry | - |

| B | Dry digestion | 1 mg/kg |

| P, K, Na, Ca, Mg | Nitric-perchloric wet digestion /ICP-OES | 0,01% |

| Al | Nitric-perchloric wet digestion /ICP-OES | 0,02% |

| Pb, As, Se, Zn | Nitric-perchloric wet digestion /ICP-OES | 2 mg/kg |

| Cu | Nitric-perchloric wet digestion /ICP-OES | 0,6 mg/kg |

| Cr, Ni | Nitric-perchloric wet digestion /ICP-OES | 0,4 mg/kg |

| Cd | Nitric-perchloric wet digestion /ICP-OES | 0,2 mg/kg |

| Hg | Wet digestion EPA 7471 cool steam | 0,01 mg/kg |

Source: VERACEL, 2015.

Table 2: Methodologies used to analyse the ashes from VERACEL.

The sludge description was done based on the National Environmental Committee Resolution (CONAMA in Portuguese) N° 375, of August 29th, 2006 which defines the criteria and procedures for the agricultural use of ETE generated sewage sludge and its derivates among other provisions. The analytic procedures follow the “Standard Methods for Examination of Water and Waste water” recommendations from APHA/AWWA.

Results and Discussion

This section presents and discusses the results of the analysis of ashes and anaerobic sludge from ETE Serraria, Porto Alegre’s DMAE.

Eucalyptus’ ashes features

Table 3 shows the average, maximum and minimum values, as well as the number of the analyzed ash samples, between 2005 and 2015.

| Parameters | Average | Max. | Min. | Samples |

|---|---|---|---|---|

| Wet granulometry | ||||

| ABNT sieve 10>2,00 mm% (m/m) | 29,34 | 46,6 | 9,16 | 17 |

| ABNT sieve 10-20 between 2,00 and 0,84 mm% (m/m) | 7,88 | 12,08 | 5,68 | 17 |

| ABNT sieve 20-50 between 0,84 and 0,3 mm% (m/m) | 9,21 | 12,2 | 6,4 | 17 |

| ABNT sieve 50<0,3 mm% (m/m) | 53,57 | 76,85 | 32,49 | 17 |

| Relative Efficiency (RE)% (m/m) | 60,65 | 83 | 41 | 17 |

| Total Neutral Relat. Power (TNRP)% (m/m) | 45,94 | 69 | 29 | 17 |

| Soil correction properties | ||||

| Neutralization power% (m/m) | 77,6 | 115 | 62 | 25 |

| General properties | ||||

| pH | 12,47 | 12,9 | 9,9 | 20 |

| Sodium% (m/m) | 0,88 | 2,1 | 0,26 | 26 |

| (CRA10)% (v/v) | 20 | 20 | 20 | 1 |

| Wet density kg/m3 | 757,75 | 995 | 152 | 8 |

| Dry density kg/m3 | 739 | 796 | 688 | 7 |

| Humidity% | 12,13 | 20 | 5 | 24 |

| Macronutrients | ||||

| Total P2O5% (m/m) | 0,56 | 0,71 | 0,25 | 18 |

| Phosphorus | 0,24 | 0,31 | 0,11 | 18 |

| K2O total% (m/m) | 4,11 | 6,2 | 1,6 | 18 |

| Potassium% | 3,41 | 5,15 | 1,33 | 18 |

| Total calcium oxide (CaO)% (m/m) | 33,89 | 39 | 24 | 27 |

| Calcium% | 24,21 | 27,86 | 17,14 | 27 |

| Total Magnesium oxide (MgO)% (m/m) | 8,04 | 21 | 3,1 | 27 |

| Magnesium% | 4,85 | 12,65 | 1,87 | 27 |

| Total sulphur% (m/m) | 0,63 | 1 | 0,29 | 6 |

| Micronutrients | ||||

| Total iron% (m/m) | 0,57 | 0,64 | 0,53 | 3 |

| Total Borum-mg/kg | 16,33 | 34 | 5 | 3 |

| Total Zinc-mg/kg | 67,75 | 87 | 44 | 4 |

| Total Manganese-mg/kg | 428 | 658 | 208 | 3 |

| Total copper mg/kg | 22,5 | 31 | 15 | 4 |

| Total Molybdenum-mg/kg | 5,15 | 10 | 0,3 | 2 |

| Total Cobalt-mg/kg | 3,5 | 5 | 2 | 2 |

| Heavy metals | ||||

| Total Arsenic-mg/kg | 2 | 2 | 2 | 3 |

| Total Aluminium% (m/m) | 1,4 | 1,4 | 1,4 | 1 |

| Total lead-mg/kg | 7,5 | 18 | 2 | 6 |

| Total Nickel-mg/kg | 38,2 | 76 | 15 | 5 |

| Total Cadmium-mg/kg | 0,52 | 1 | 0,2 | 6 |

| Total chromium-mg/kg | 22,5 | 28 | 11 | 4 |

| Hexavalent chromium-mg/kg | 7 | 7 | 7 | 1 |

| Trivalent chromium-mg/kg | 20 | 20 | 20 | 1 |

| Total Mercury-mg/kg | 0,03 | 0,06 | 0,02 | 5 |

| Total Selenium-mg/kg | 3,33 | 4 | 2 | 3 |

Source: VIDA – Ecological development, 2014.

Table 3: Analysis of the physical and chemical parameter of the ashes.

Considering that ETE Serraria became operational in 2014, this is the first study on the features and potential agronomical use of the sludge from this facility. The raw sludge average parameter values were compared to those of other ETEs.

Agronomical potential of raw, control and mixed sludge

This section contains the description of all the evaluated parameters of the raw, control and mixed with ash sludge in the concentrations of 30%, 50% and 100% in relation to the dry sludge content.

Agronomical potential: One of the recommendations pertaining to the use of sludge on agronomical soil, according to the 375 CONAMA Resolution of 2006, is the determination of the agronomical potential. In keeping with the aforementioned CONAMA resolution, the results of agronomical potential parameters of the raw, control and hygienized sludges are presented below.

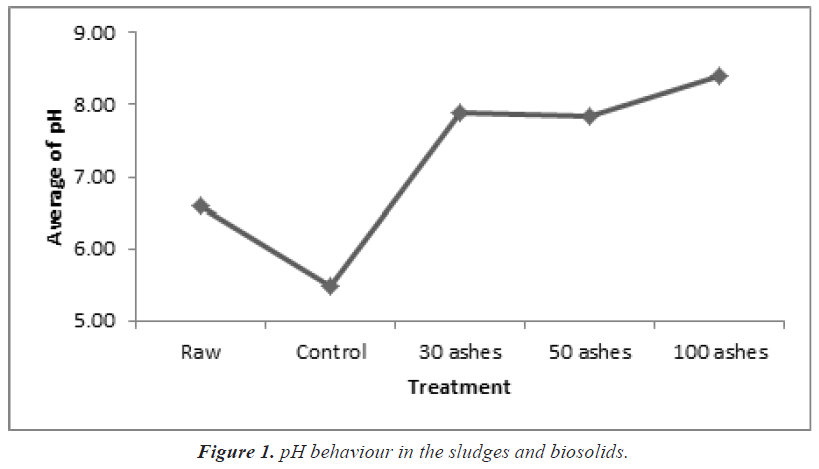

pH: The pH values of the different types of sludge/biosolids analysed were submitted to variance analysis and meaningful differences between raw sludge (group 1), hygienized sludge in the proportion of 30% and 50% (group 2) and sludge hygienized with 100% ashes (group 3) were noticed, as shown in Table 4 and Figure 1 below.

| Groups | 1 | 2 | 3 |

|---|---|---|---|

| Control | 5,48 ± 0,54 | - | - |

| Raw | 6,60 ± 0,70 | 6,60 ± 0,70 | - |

| 50% ashes | - | 7,85 ± 0,53 | 7,85 ± 0,53 |

| 30% ashes | - | 7,88 ± 0,35 | 7,88 ± 0,35 |

| 100% ashes | - | - | 8,40 ± 0,14 |

Table 4: Average pH values of the various sludges and biosolids with standard deviation.

As shown in Table 4, the raw and control sludges, (Group 1) Have an acid pH. The control sludge, due to the degradation of the raw sludge, has a visibly lower pH value in comparison to the later. The pH of the sludges treated with 30% and 50% (group 2) ashes are similar, displaying values with basic tendencies. The sludge treated with 100% ashes (group 3) showed a basic behaviour as well. If compared to the control sludge, the addition of ashes significantly increased the pH values. The table shows that the higher the percentage of ash concentration in the mixture, the higher is the pH value as well.

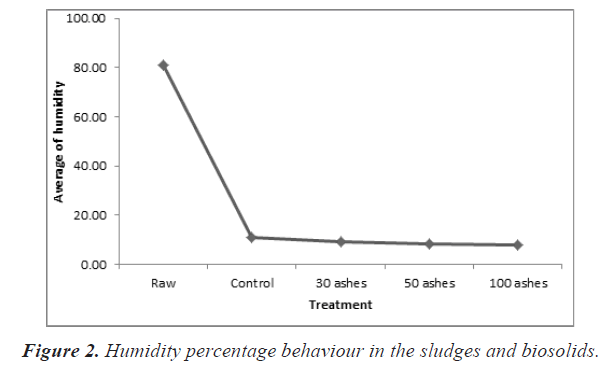

Humidity: The observed humidity values were submitted to a variance analysis and meaningful differences were noticed by F test between the raw sludge, (group 3), control sludge, (group 2) and the hygienized sludges in the three ratios, (group 1), as shown in Table 5 and Figure 2.

| Groups | 1 | 2 | 3 |

|---|---|---|---|

| 100% ashes | 7,85 ± 0,92 | - | - |

| 50% ashes | 8,23 ± 1,08 | - | - |

| 30% ashes | 9,00 ± 0,45 | - | - |

| Control | - | 10,95 ± 0,86 | - |

| Raw | - | - | 81,00 ± 0,43 |

Table 5: Humidity percentage with standard deviation in the different sludges and biossolids.

Based on the data in Figure 2, compared to the control sludge, the addition of ashes, significantly diminishes the humidity, that is, as the ashes’ concentration increased, so did the solid content and, consequently, the humidity reduced.

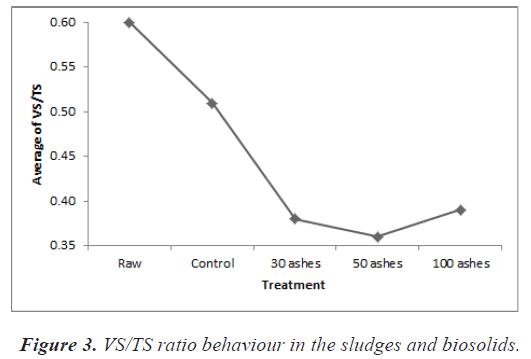

Volatile and total solids’ (VS/TS) relation: The volatile and total solids’ concentrations’ relations varied depending on the ash dosages, decreasing as the ash concentration used in the hygienization process increased.

The observed of the VS/TS ratio were submitted to variance analysis and meaningful differences were noticed by the F test, between raw sludge (group 2), and all three hygienized sludges (group 1), as shown in Table 6 and Figure 3.

| Groups | 1 | 2 |

|---|---|---|

| 50% ashes | 0,36 ± 0,026 | - |

| 30% ashes | 0,38 ± 0,020 | - |

| 100% ashes | 0,39 ± 0,169 | - |

| Control | 0,51 ± 0,117 | 0,51 ± 0,117 |

| Raw | - | 0,60 ± 0,003 |

Table 6: VS/TS ratio values and standard variation in the various sludges.

In some studies on chemical stabilization using lime, researchers noticed that volatile solids were not reduced but changes in the chemical and physical properties of the sludge occurred. Lima studying sludge submitted to draining and hygienization with lime in agricultural greenhouses, reported a slight reduction of volatile solids in relation to total solids which may be due to chemical oxidation of the organic matter available in the sludge because of the pH increase, leading to the diminishment of the ratio. Andreoli reported the loss of volatile solids when the pH was incremented [12]. In the present study, the VS/TS ratio values were less than 0.7, as established by CONAMA resolution 375/2006, showing that the sludge was stabilized. The difference was more noticeable in the hygienized sludges.

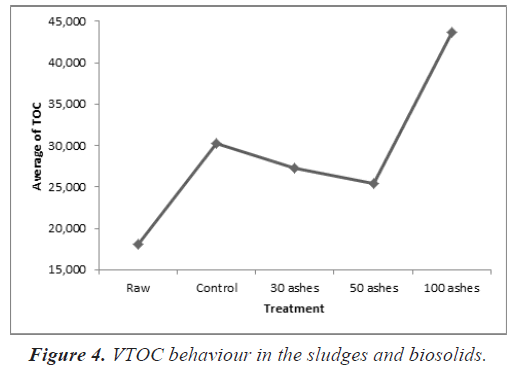

Total organic carbon: Table 7 and Figure 4 present the average TOC values in the raw sample of anaerobic sludge, in the control sludge and in the samples treated with 30%, 50% and 100% of ashes. The observed TOC values were submitted to the variance analysis and meaningful differences were noticed by the F test, between the hygienized sludge with 100% ashes (group 2) in relation to the raw sludge and the hygienized with 30% and 50% ashes (group 1), as shown in Table 7.

| Groups | 1 | 2 | 3 |

|---|---|---|---|

| Raw | 18.048,0 ± 731,9 | - | - |

| 50% ashes | 25.380,5 ± 7.520,8 | - | - |

| 30% ashes | 27.309,0 ± 6.458,6 | - | - |

| Control | 30.894,0 ± 8.940,7 | 30.894,0 ± 8.940,7 | - |

| 100% ashes | - | 43.666,0 ± 868,3 | 81,00 ± 0,43 |

Table 7: TOC values in mg/kg and standard deviation in the various sludges and biosolids.

The data in Figure 4 show the behaviour of TOC was not according to standards if compared to the quantity of ashes.

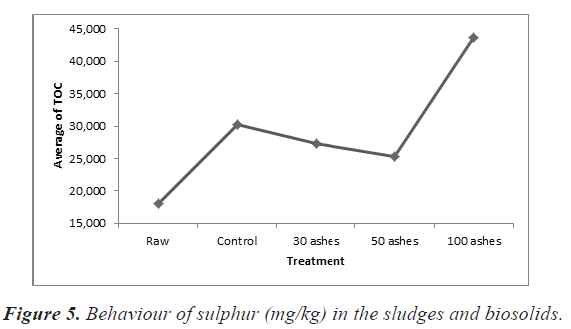

Sulphur: The following sulphur concentration averages were found: 18.096 mg/kg in the raw sludge, 16.410 mg/ kg in the control sludge, 15.596 mg/kg in the sludge treated with 30% ashes in relation to the MS content; 15.532 mg/ kg in the sludge treated with 50% ashes and; 15.438 mg/kg in the sludge treated with 100% ashes. The sulphur values were submitted to the variance analysis and no meaningful differences were noticed by the F test. Figures 3-5 displays the behaviour of sulphur in the analysed sludges.

Based on the sulphur results obtained (Figure 5), it is noticeable that for all the three ashes’ concentrations adopted, there was a slight reduction of the content of that element. Statistically, the variance analysis indicated that there is no meaningful difference amongst the five situations observable in Figure 5.

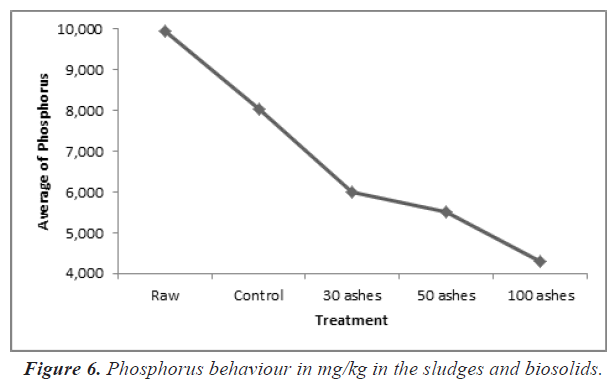

Phosphorus: The following average phosphorus values were found: 9.951 mg/kg for the raw sludge; 8.046 mg/kg for control sludge; 6.001 mg/kg for the sludge hygienized with 30% ashes; 5.512 mg/kg for the sludge hygienized with 50% ashes and; 4.303 mg/kg for the sludge hygienized with 100% ashes (Figure 6). The raw sludge displayed the highest value of all, however, the variance analysis of the phosphorus values showed no meaningful difference amongst the different combinations.

In Figure 6, it is noticeable that there is a reduction of the phosphorus content from raw sludge to control sludge and the same happens in the higyenized sludge when compared to the raw sludge. This tendency is similar to that reported by Malta and Tsutiya, in a study on the liming of ETE Lavapés’ sludge, in São José dos Campos-São Paulo. In Malta and Tsutiya’s study, the lime dosage was inversely proportional to the phosphorus concentration, that is, as the lime dosage increased, the phosphorus concentration decreased [13].

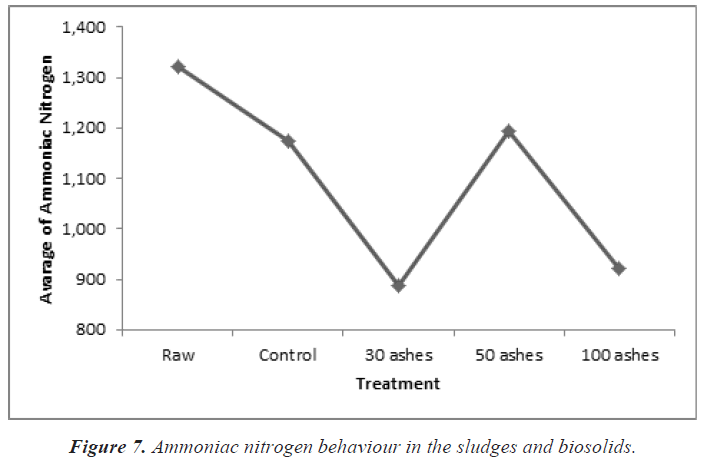

Ammoniac nitrogen: The sludge under analysis did not contain nitrogen in the form of either nitrite or nitrate. This is due to the fact that the nitrification process (ammonium oxidation into nitrite and form nitrite to nitrate). The following ammoniac nitrate values were determined, in mg/kg: 1.322, 1.174, 887.5, 1.195 and 921 for raw sludge, control sludge and sludge hygienized with 30%, 50% and 100% ashes, respectively. Looking at these values an irregularity in the concentrations of nitrogen is noticeable as the ash dosage increases. The variance analysis did not detect any meaningful difference in the ammoniac nitrogen values. Figure 7 shows the element’s behaviour in sludge.

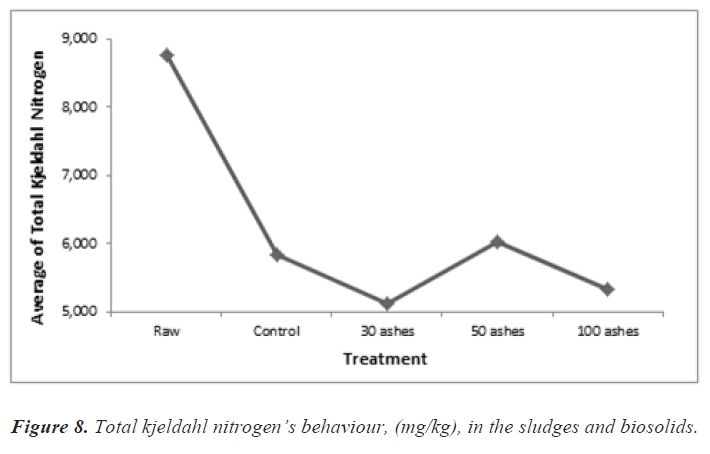

Total kjeldahl nitrogen: For the TKN the following concentrations in Table 8 were observed.

The TKN values observed, when submitted to variance analysis, displayed meaningful differences for the F test, between raw sludge, (group 2), and the sludge hygienized with 30% ashes, (group 1). Figure 8 was generated using the data in Tables 3-6 which displays the behaviour of TKN in the sludges and biosolids under analysis.

| Groups | 1 | 2 |

|---|---|---|

| 30% ashes | 5.129,3 ± 1.243,0 | - |

| 100% ashes | 5.336,0 ± 155,0 | 5.336,0 ± 155,0 |

| Control | 5.845,5 ± 1.206,0 | 5.845,5 ± 1.206,0 |

| 50% ashes | 6.019,5 ± 1.804,0 | 6.019,5 ± 1.804,0 |

| Raw | - | 8.763 ± 1.674,0 |

Table 8: TKN values (in mg/kg) and standard deviation in the different sludges and biosolids.

The data in Figure 8 show that there is lack of regularity in the behaviour of this element, that is, it displays a non-standard behaviour as the ash dosage is increased. If compared to other organic matter used as fertilizer in agriculture, like stillage, for example, with 600 mg/kg of dry matter, or garbage composite with 6000 mg/kg, sludge has superior TKN levels.

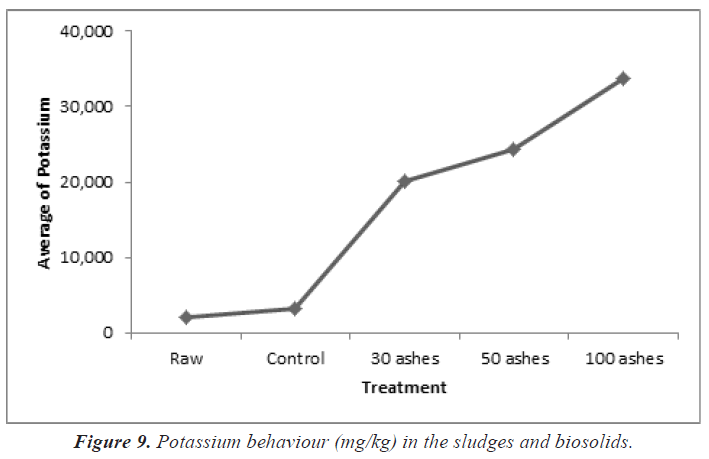

Potassium: Table 9 and Figure 9 display the average potassium concentrations in raw sludge, control sludge and hygienized with 30%, 50% and 100% of ashes [13].

| Groups | 1 | 2 |

|---|---|---|

| Raw | 1.983 ± 301 | - |

| Control | 3.135 ± 1942 | 3.135 ± 1.942 |

| 30% ashes | - | 20.038 ± 9.205 |

| 50% ashes | - | 24.288 ± 8.558 |

| 100% ashes | - | 33.766 ± 6.783 |

Table 9: Potassium concentrations (mg/kg) and standard variation in the different sludges and biosolids.

The potassium concentration values were submitted to variance analysis and meaningful differences were noticed, by F test, between raw sludge, (group 1), and the variously hygyenized sludges, (group 2) as shown in Table 9.

In Figure 9, it is noticeable the increase of vegetable biomass ashes’ concentration in the biosolids leads to the increment of potassium concentration in them, making the input of potassium through mineral fertilization, expendable.

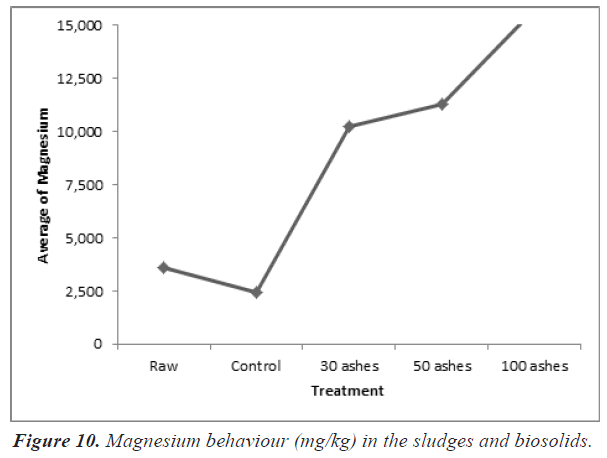

Magnesium: The magnesium concentration values found were submitted to variance analysis, and meaningful differences were noticed, through F test, between the control sludge, (group 1), sludge hygienized with 30% of ashes (group 2) and those hygienized with 50 and 100% ashes, (group 3), as shown in Table 10 and Figure 10 which shows the behaviour of magnesium in the analyzed sludges.

| Groups | 1 | 2 | 3 |

|---|---|---|---|

| Control | 2.465 ± 1.017 | - | |

| Raw | 3.588 ± 79 | 3.588 ± 579 | - |

| 30% ashes | - | 10.236 ± 2.238 | 10.2362 ± 238 |

| 50% ashes | - | - | 11.285 ± 1.674 |

| 100% ashes | - | - | 15.715 ± 3.042 |

Table 10: Magnesium concentration values, (mg/kg), and standard variation in the various sludges and biosolids.

In Figure 10, it is evident that increment of ash concentration in the sludge hygienization increases the magnesium content in the biosolids. This phenomenon is similar to what happens in the hygienization using lime. Compared to other study findings, it noticeable that the values found in this study are superior to those found at ETE Barueri (4.500 mg/kg), ETE Franca, (2.200 mg/kg), ETE Curitiba, (6.000 mg/kg), ETE Paranavaí (3.000 mg/ kg) or ETE Jundiaí (1.300 mg/kg) [14].

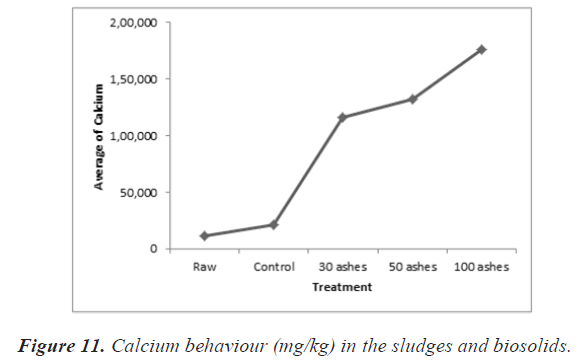

Calcium: The calcium concentrations in the raw, control sludges and the sludges hygienized with 30%, 50% e and 100% of ashes are presented in Table 11 and Figure 11.

| Groups | 1 | 2 | 3 |

|---|---|---|---|

| Raw | 11.216,75 ± 2.831 | - | - |

| Control | 21.365,25 ± 12.035 | - | - |

| 30% ashes | - | 11.6356,25 ± 55.534 | 10.2362 ± 238 |

| 50% ashes | - | 132.100,00 ± 41.624 | 11.285 ± 1.674 |

| 100% ashes | - | 175.787,00 ± 43.860 | 15.715 ± 3.042 |

Table 11: Calcium concentration (mg/kg) and standard deviation in the various sludges and biosolids.

The calcium values were submitted to variance analysis and meaningful differences were noticed through F test between the raw and control sludges, (group 1) and the three hygienized sludges, (group 2). Figure 11 shows the behaviour of calcium in the sludges and biosolids under analysis.

In relation to calcium, it was noticed that the increase of the concentration of ashes in the hygienization process boosts its concentration in the biosolid. This phenomenon is similar to what happens in the hygienization with lime. In comparison to the control sludge, the addition of ashes meaningfully increased the calcium content.

The values of calcium concentration found in the present research are similar to those found in other studies: ETE Barueri (47.800 mg/kg); ETE Franca (24.800 mg/kg); ETE Curitiba (15.900 mg/kg); ETE Paranavai (8.300 mg/kg) and ETE Jundiaí (6.600 mg/kg) [15]. Malta and Tsutiya, in an ETE Lavapés sludge liming experiment, in São José dos Campos-São Paulo, noticed that the increase of lime dosage in the sludge also resulted in calcium concentration increase.

Conclusion

From this study the following conclusions were drawn:

The vegetable biomass ashes from VERACEL Company present substantial alkaline characteristics. Mixing the anaerobic sludge with ashes is an advantageous process as the later contribute with potassium, calcium and magnesium and the sludge provided nitrogen and phosphorus, generating biosolids with the necessary nutrients to the agricultural soils. The rational combination of residues proposed in this study is adequate to rural communities in developing countries where the population is predominantly rural and uses untreated anaerobic sludge from septic tanks and “black pits” as fertilizers. These communities, which practice small-scale agriculture, use firewood as a domestic fuel, which makes the combination of the residues possible because there are readily available to them, without transportation costs.

References

- Pedroza MM, Vieira GEG, Sousa JF, et al. Sewage sludge production and treatment: A review. Liberato Magazine. 2010;11(16):147-57.

- Harrison R, Xue D, Henry C, et al. Long-term effects of heavy applications of biosolids on organic matter and nutrient content of a coarse-texture forest soil. For Ecol Manage. 1994;66(1-3):165-77.

- WPCF. Sludge Stabilization-Manual of practice FD-9. Task force on sludge stabilization. 1985.

- Saramaki J. Effects of wood ash and nitrogen fertilization on soil chemical properties, soil microbial processes and stand growth in a scots pine stand. For Ecol manage. 2012;278:63-70.

- Norstrom SH, Bylund D, Vestin JLK, et al. Initial effects of wood ash application to soil and soil solution chemistry in a small, boreal catchment. Geoderma. 2012;187:85-93.

- Ferreiro A, Merino A, Diaz N, et al. Improving the effectiveness of wood ash fertilization in mixed mountain pastures. Grass Forage Sci. 2011;66(3):337-50.

- Dahl O, Nurmesniemi H, Poykio R, et al. Comparison of the characteristics of botton ash and fly ash from a medium-size municipal district heating plant incinerating forest residues and peat in a fluidized-bed boiler. Fuel processing technology. 2009;90(7-8):871-8.

- Arshad MA, Soon YK, Azooz RH, et al. Soil and crop response to wood ash and lime application in acidic soils. Agron J. 2012;104(3):715-21.

- Nascimento BB. Forest biomass ashes’ effect on soil fertility imazethapyr sorption in acid soils. 2013.

- Saarsalmi A, Smolander A, Kukkola M, et al. Vegetable ash as a corrective and fertilizer for Marandu and Xaraés grass. 2012.

- Etiegni L, Campbell AG. Physical and chemical characteristics of wood ash. Bioresour Technol. 1991;37(2):173-8.

- Andreoli CV. Sanitary solid residues: Processing, recycling and final disposition Rio de Janeiro: Rima, Abes. 2001:257.

- Malta LRS, Tsutiya MT. Calcic stabilization’s optimization of the biosolid produced at ETE Lavapés of São Jose do Campo/SP, for agricultural use. Rio de Janeiro: Abes. 2003.

- Bettiol W, Camargo OA. The disposition of sewage sludge in agricultural soil. 2006:25-36.

- Wang P, Olsson BA, Arvidsson H, et al. Effects of nutrient compensation following whole-tree harvesting on soil and soil water chemistry in a young Norway spruce stand. Plant and Soil. 2010;336(1-2):323-36.