Research Article - Materials Science and Nanotechnology (2017) Volume 1, Issue 2

An experimental characterization of physical properties of timber woods.

Annu Rani*, Jayant Singh and TP Singh

G. B. Pant University of Agriculture and Technology, Pantnagar, India

- *Corresponding Author:

- Annu Rani

G. B. Pant University of Agriculture and Technology

Pantnagar

India

Tel: +91-9756521753

E-mail: annuchaudhary39@gmail.com

Accepted date: September 25, 2017

Citation: Rani A, Singh J, Singh TP. An experimental characterization of physical properties of timber woods. Mater Sci Nanotechnol. 2017;1(2):41-45.

DOI: 10.35841/nanotechnology.1.2.41-45

Visit for more related articles at Materials Science and NanotechnologyAbstract

The present investigation was carried out to determine the different physical properties of various types of timbers used for agricultural implements in India. This study provides information for selection criteria of wood to make a different component of agriculture implement and tools. This article consists of detailed material and methods used in the study. This study was mainly targeted on utilization of different type of wood for their use to make different components of agricultural implements and tools.

Keywords

Physical properties, Woods, Agriculture, Density.

Introduction

Agriculture in India had developed in remote antiquity, and down to the 18th century, India ranked among a few developed countries of the globe. Indigenous tools were basic but welldesigned suit farmer’s needs. Traditionally farmers have been using a variety of tools in their everyday life, often for agricultural operations and household purpose. Agricultural implements used in 18th and 19th centuries were mostly hand operated and animal drawn. The fresh development in new designs of implements and tools was noticed around independence. Most of the wooden tools, implements use local wood materials – different timbers for particular tools and strings for various uses come from different plants [1-9]. Agricultural practices require certain traditional techniques including tools and implements due to steep and hilly terrain comprising of shallow and stony soils. Present study has been undertaken to describe agricultural tools and implements from the local plants to facilitate the agriculture during harsh condition. Besides these agricultural implements, author documented the traditional knowledge of locals about the use of plants in making the handles of harvesting tools on the basis of their preference and choice. Traditional agricultural tools and implements were made up of locally available materials like stone, wood and iron, constructed at local level or standardized factory-made implements. These tools and implements were economical in term of labor, money and time saving. Also, they are operated easily without any special skills. Each of these tools and implements are usually used in connection with specific operation in the sequence of agricultural operations; land preparation, sowing, weeding, irrigation, harvesting, postharvesting operations and transportation.

Observing the above facts, the physical and mechanical properties of wood are important factors used in determining the suitability and application of wood material, these in turn depends on the wood species. In view of the preceding discussion, the present study was undertaken to this study was conducted to determine the physical and mechanical properties of selected Timbers to be used in agricultural implements in Pantnagar, Udam Singh Nagar, Uttarakhand with following major objectives. Bali and Singh [2] investigated the physical properties of Teak collected from a Vilonia range of the Gorakhpur forest division of Uttar Pradesh. The physical properties such as specific gravity, moisture content and density of Teak were 0.578, 42.1% and 821 kg/cm3, respectively. Shukla et al. [7] studied the physical properties of Quercus Dilatata collected from Chachpur range, Jubbal forest division Himachal Pradesh. The average specific gravity of Quercus Dilatata was 0.760 and percent moisture content was 56.9 and density was 1192 kg/m3. The radial, tangential and volumetric shrinkage was 6.0, 10.2 and19.6%, respectively. Josue [5] investigated for nine year old trees and Xylia xylocarpa were taken from a small plot at Luasong, Tawau and Sabah. The average basic density, oven-dry density and green moisture content of Xylia xylocarpa were 0.72 g/cm3, 0.78 g/cm3and 49.8%, respectively. Elzaki et al. [3] investigated the mechanical properties of wood of 20 year old Lusitanica from Jebel Marra field Western Sudan to resolve its mechanical properties as a probable different wood. The end results for the mechanical properties were correlated with the aspect of the equation cypress species from India and Costa Rica. The results displayed that the moderate value the modulus of rupture “693.0 kPa/cm2” was reduced than that of the Indian cypress “763.0 kPa/cm2” but higher than for the Costa Rican cypress. The elements of elasticity were 142.7 kg/m2 express good rigidity properties. The shear stress was decreased than that of the Indian cypress, but comparable to a Costa Rican. Thulasidas and Bhatt [8] studied mechanical properties of teak wood mature in homegrown arboriculture and the objective factors affecting timber strength were reviewed in correlation with that of a typical woodland orchard. No significant inequality was realized in modulus of elasticity and modulus of rupture with respect to wet, dry and orchard sites and the values are balanced correlated along the basic teak. Hossain and Abdul Awal [4] studied physical properties, strength and endurance of few timber species financially used in Bangladesh. Seven timber species, namely Teak, Sal, Sil Korai, Rain Tree, Jam, Jackfruit, and Mango were tested for physical and mechanical properties following ASTM standards.

Experimental section

Wood is a natural polymer and its molecular structure is established on the cellulose chain whose cell wall comprises cellulose fibers which were laterally arranged to its axis, similar to a natural human hair. The wood is the intermediate and in fact the main zone of the tree. Wood subsists of four main chemical groups represented in Table 1. The cellulose and hemicellulose groups are the carbohydrates (sugar molecules) which make up the majority of the cell wall. Lignin performs as a "glue" to bind the cells together into a stiff/strong material. The extracts are chemicals that are deposited in the cells and provide unique properties to wood, such as the natural resistance to biological deterioration. Woods with a high degree of natural resistance have approximately high percentage of biocidal extracts. The total extractive content of few species can be as high as 20 to 30%; these species commonly have a high proportion of biocidal extracts. Wood on exposure to the atmosphere either absorbs or loses moisture depending upon whether it contains less or more moisture than the atmosphere. The wood tissues lose moisture when subjected to drying conditions. Water is lost first from the cavities and then from the cell walls. Wood shrinks most severely in the tangential direction and lowers so in radial direction, there is minimum almost negligible shrinkage in longitudinal direction. The cell walls absorb big amount of water, resulting in swelling of its surface when exposed to moisture. Wood has more strength in the longitudinal direction as correlated to transverse direction due to its directed cell structure. The strength of wood is defined by its compressive strength, tensile strength and flexural strength. Ten representative trees of average growth and health of wood Yellow Teak, Red cedar, Sheesham, Lebbeck, Java plum, Mango, Margosa, Eucalyptus, Teak and Sal from mixed and monoculture plantation were compiled from Pantnagar, District of Udam Singh Nagar (Table 1).

Before conducting the test, moisture content was assessed by weighing (to 0.001 g accuracy) before and after oven drying at 103°C ± 2°C for 24 h have been done in accordance with different test procedure. A physical property is any property that is perceptible whose value an express state of a physical system [9]. The deformation in the physical properties of a system can be used to define its transformations or evolutions between its temporary states. Physical properties are generally referred to as noticeable.

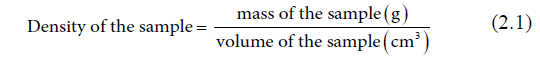

Density

Density is one of the best essential physical properties of the material. It is consistency indicated by the dimensionless quantity "specific gravity" or "relative density", i.e., the ratio of the density of the material to that of a standard material, usually water. The density of a material varies with temperature and pressure. This deviation is commonly small for solids and liquids, but much greater for gases. Increasing the pressure on an object decreases the volume of the object and thus increases its density. Increasing the temperature of a substance decreases its density by increasing its volume. Density is an accelerated property in that increasing the amount of a substance does not increase its density; rather it increases its mass. For determination of density of samples of different models were first weighed on electronic weighing machine individually, and then were dipped individually into 50 ml of water kept into a cylindrical beaker of volume 100 ml as shown in Plate 3.12. The rise in volume had been noted down.

Thus,

The mass of the sample = m, g

Volume of water taken = 50, ml

Volume of the sample and water = (v+50), ml

Volume of sample = {(v+50) – 50}

= v, ml

Hence,

Water absorption and thickness swelling test

The water absorption test was conducted with the method ASTM D 1037. Wood in storage is defined to both regular water absorption and desorption processes. The water absorption by wood generally considers big importance, exclusively in the structural usage of wood. Samples are measured, weighed and placed under a great one-inch below the water-line in a water bath maintained at approximately 18°C [9,10]. After 2 h and 24 h the specimens are removed from the water, weighed, and the thickness is measured with vernier calipers. The percent change from the original thickness represents the thickness swell and the percent weight change from the original weight represents the water absorption. Specimens are reconditioned to equilibrium moisture content and measured again to regulate the non-recoverable thickness swell.

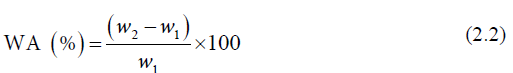

Water absorption, WA is calculated by,

Where,

w_1=Initial weight of specimen, g

w_2=Specimen weight after N hours of water soaking, g And Thickness swelling, TS is calculated by,

Where

T_1=Specimen thickness after N hours of water soaking, mm

T_2=Intial thickness of specimen, mm

Results and Discussion

The different physical properties of selected wood were measured and discussed under this section.

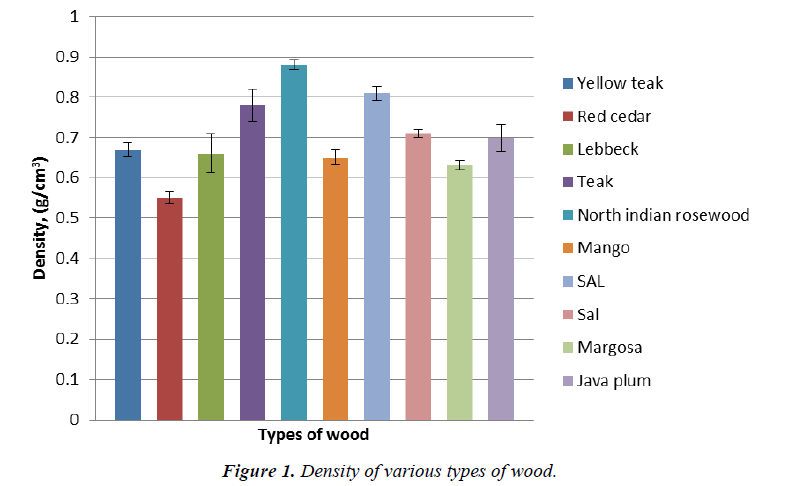

Density

The experimental densities of ten different woods are presented in Table 1 and Figure 1. The Density of various types of wood viz Sal, Teak, North Indian Rosewood, Mango, Red cedar, Yellow teak, Margosa, Java plum, Eucalyptus and Lebbeck which were recorded as 0.81, 0.78, 0.88, 0.65, 0.55, 0.67, 0.63, 0.70, 0.71 and 0.66 g/cm3 respectively and their Standard deviations were found as 0.016, 0.040, 0.012, 0.019, 0.015, 0.018, 0.013, 0.033, 0.009 and 0.048, respectively. It has been cleared from the table that North Indian Rosewood has highest wood density followed by Sal, Teak, Eucalyptus, Lebbeck and Margosa, Yellow Teak, Java plum and Red Cedar in a decreasing order of densities. Yellow teak, Java Plum, Mango and Teak fall in the category of medium density of wood. On the basis of the value of wood density, it is evident that the North Indian Rose wood can be used for agricultural implements and other work that require high strength wood. The result has shown that Red Cedar wood has low density wood.

| S. No. | Trade Name | Hindi name | English name | Botanical name |

|---|---|---|---|---|

| 1 | Haldu | Haldu | Yellow teak | Haldinia Cardifolia |

| 2 | Toon | Tun | Red cedar | Toona ciliate |

| 3 | Sissoo | Sheesham | North Indian rosewood | Dalbergia sissoo |

| 4 | Mysore gum | Eucalyptus | Eucalyptus | Eucalyptus tereticornis |

| 5 | Margosa | Neem | Margosa | Azadirachta indica |

| 6 | Teak | Sagun | Teak | Tectona grandis |

| 7 | Mango | Aam | Mango | Mangifera indica |

| 8 | Jamun | Jamun | Java Plum | Syzygium cumini |

| 9 | Lebbeck | Siris | Lebbeck | Albizia lebbeck |

| 10 | Balau | Sal | Sal | Shorea robusta |

Table 1. Nomenclature of different types of wood.

Water absorption and thickness swelling

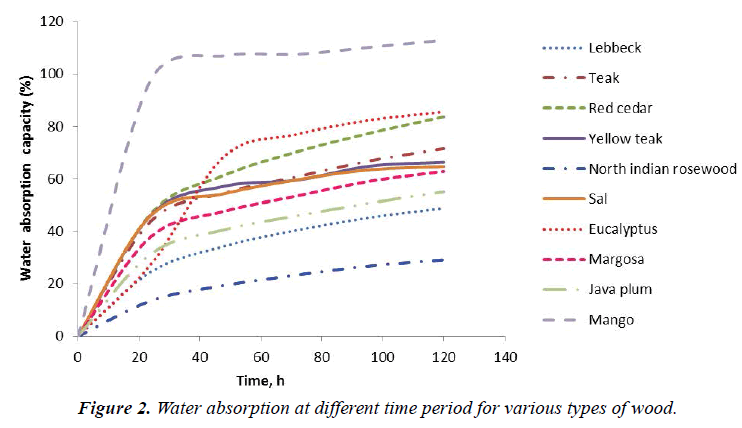

Rectangular specimens of 20 × 20 × 60 mm3 (width × thickness × length) as per ASTM D 1037 test Code were used for water absorption and thickness swelling test. The water absorption in sample Lebbeck, Teak, Red cedar, Yellow teak, North Indian Rosewood, Sal, Eucalyptus, Margosa, Java plum, Margosa and Mango were 48.95, 71.56, 83.70, 66.41, 29.17, 64.75, 85.64, 62.92, 55.12 and 112.97%, respectively after 120 h of water emersion. According to the observations on water absorptivity by different woods, North Indian rosewood rank first as it absorbs less water as compare to other types of wood followed by Lebbeck which rank second, Java plum rank third, Margosa rank fourth, Sal rank fifth, Yellow teak rank sixth, Teak rank seventh, Red cedar rank eight, Eucalyptus rank ninth and Mango rank tenth. Hence, North Indian Rose wood which has the lowest water absorptivity can be recommended at farm level. It is clear that from Figure 2 that water absorption in wt.%, increased with immersion time. The water absorption behavior of natural fibers also depends on free hydroxyl groups present in cellulose and hemicellulose, which are accessible by water. Besides that, other factors such as porosity void content limen size and fiber matrix adhesion also affect water absorption behavior of woods. Mango wood showed highest percent water absorption while North Indian Rosewood wood confirmed lowest percent water absorption, than the other woods. Water absorption capacity for woods varied between 29.17 to 112.97%. In all the treatments, percentage moisture absorption increases steadily at an initial stage and then tend to level off after 48 h of fluid emersion followed by a saturation point. The minimum water absorption 29.17% was observed in North Indian rosewood after 120 h of fluid emersion (Figure 2).

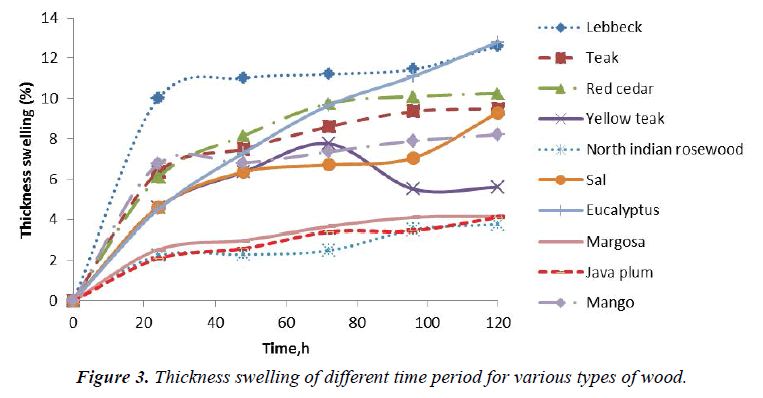

The reason for higher initial water absorption rate can also be interpreted by the diffusion phenomenon. Diffusion is the procedure by which a fluid migrates and spreads itself through capillaries, vessels and cellular walls of wood. Water is present in wood in two forms: interstitial water and bound water. The interstitial water is contained in the cellular cavities and dependent water is retained in the cell walls. The rate of water absorption depends upon the difference between the saturation water content and the water content at a given time, which is called the driving force. In other words, the moisture diffusion into the wood takes place because of the moisture gradient between the surface and the center. As the absorption proceeds, the water content increases, diminishing the driving force and consequently the absorption rate. The process ceases when the grains attain the saturation in the moisture content. Generally, the force which is retained within the interstitial water molecules is relatively weaker than the one exerted on the bound water molecules. During the diffusion process, a difference in concentration between the various cellular layers is established. Water migrates from the more concentrated medium towards the less concentrated one (Figure 3).

The thickness swelling of the sample Lebbeck, Teak, Red cedar, Yellow teak, North Indian Rosewood, Sal, Eucalyptus, Margosa, Java plum and mango wood it is shown in Figure 3 where the thickness swelling of different woods were 12.6, 9.5, 10.25, 5.6, 3.75, 9.3, 12.8, 4.15, 4.1 and 8.2 mm, respectively after 120 h of fluid emersion. According to the observation on thickness swelling by different woods used in experiment North Indian rosewood rank first as it swelled less as compare to other types of wood followed by Java Plum, Margosa, Yellow Teak, Mango, Sal, Teak, Red Cedar, Lebbeck and Eucalyptus. It has been observed that Eucalyptus swelled maximum among other types of woods used in the experiment. Hence, Eucalyptus is not recommended at farm or industrial level. To improve the water resistance and reduce the thickness swelling, add wax (0.5-1%) to the mixture of adhesive and particles during the manufacturing process [11]. Eucalyptus has the highest percentage volume swelling, which indicates the capacity of this wood species to swell when expose to moisture environment. North Indian rosewood, Java plum, Margosa and Yellow Teak has the lowest volume percentage values and hence their uses and application cannot be much affected by moisture of rainfall.

Conclusion

In this article, the authors performed experimental work to evaluate various physical properties of timber woods. Since, most of the agricultural implements in India are made up of wood; therefore, this study would be useful to various farmers and agricultural scientists. We have categorised the selection criteria of wood to make a different component of agriculture implement and tools. This study was chiefly embattled on utilization of diverse type of wood for their usage to make different components of agricultural implements and tools.

Water absorption and thickness swelling test proves that Mango has the highest percentage of water absorption; on the other hand North Dalbergia latifolia wood has the lowest water absorption capacity when compared to other woods.

References

- ASTM D 1037. Standard test methods for evaluating properties of wood-base fiber and particle panel materials. 1999

- Bali BI, Singh KR. A note on the physical and mechanical properties of Tectona grandis (teak) from Gorakhpur division of Uttar Pradesh. J Timb Assoc (India). 1983;24(1):25-34.

- Elzaki OT, Otuk, S, Khider T. Sulfur-free pulping of Crateva adansnii from Sudan. Journal of Forest Products and Industries. 2012;(1):23-6.

- Hossain M, Abdul Awal ASM. Mechanical properties and durability of some selected timber species. Malay J Civil Eng. 2012;24(1):67-84.

- Josue J. Some wood properties of Xylia xylocarpa planted in Sabah. Sepilok Bull. 2004;1: 1-5.

- Karthikeyan D, Veeraragavathatham D, Karpagam, et al. Traditional tools in agricultural practices. Indian Journal of Traditional Knowledge. 2009;8:(2) 212-7.

- Shukla NK, Guru RD, Khanduri AK, et al. Physical and mechanical properties of Quercus dilatata and Grewia ossptiva from Himachal Pradesh. J Timb Dev Assoc (India). 1990;36(3):15-26.

- Thulasidas PK, Bhatt KM. Mechanical properties and wood structure characteristics of 35 year old home-garden teak from wet and dry localities of Kerala: Indian comparison with plantation teak. J Indian Acad Wood Sci. 2012;9(1):23-32.

- Verma A, Singh VK, Verma SK, et al. Human hair: A biodegradable composite fiber - A review. Int J Waste Resour. 2016;6(206):2.

- Verma A, Singh VK. Experimental investigations on thermal properties of coconut shell particles in DAP solution for use in green composite applications. J Material Sci Eng. 2016;5(242):2169-3022.

- Zelalem G, Pradeep P, Omprakash S. The influence of physical and mechanical properties on quality of wood produced from Pinus patula tree grown at Arsi forest. Adv Res J Plant Anim Sci. 2014;2(4):32-41.