Commentary - Materials Science and Nanotechnology (2018) Volume 2, Issue 1

Route of advanced material to unlock new energy resources.

Lei Zhao*, Zhiyue Xu, Baker Hughes, A GE Company14990 Yorktown Plaza Dr, Houston, TX 77040, USA

- *Corresponding Author:

- Lei Zhao

14990, Yorktown Plaza Dr Houston

TX 77040 USA

E-mail: Lei.zhao3@BHGE.com

Accepted date: May 05, 2018

Citation: Zhao L, Xu Z, Hughes B. Route of advanced material to unlock new energy resources. Mater Sci Nanotechnol. 2018;2(1):29-31.

DOI: 10.35841/nanotechnology.2.1.29-31

Visit for more related articles at Materials Science and NanotechnologyAbstract

Lack of high temperature high pressure (HTHP) elastic seal has been the bottleneck for the energy industry to economically and safely explore geothermal energy and heavy oils, which is extremely abundant but under-developed. Once completely unlocked, it would be one of the main alternative resources to compensate for gradual dearth of easy-to reach traditional oil and gas reservoirs. In exploration of these resources, hot fluids are required to be safely sealed in an enclosed system, the temperature of which could easily reach to 600°F+. However, rubberscurrent material options downhole sealing applications- have found prone to decompose when temperatures approach 600°F and even lower in wet wellbore condition. It is no longer suitable for heavy oil and geothermal wells. On the other hand, metal to metal sealing systems may have the temperature tolerance, but lacks necessary elasticity to provide reliable seal over rough sealing surfaces, the most common working conditions in oil and gas industry. Elastic Carbon Composite (ECC) combines the sealing capacity from expanded graphite (EG) with high mechanical strength of metal material. This novel seal material exhibits excellent thermal/ chemical stability, high mechanical strength and reasonable elasticity, thus fills the seal material gap where rubber does not have enough temperature rating and metal lacks enough elasticity to work reliably. Seal produced made from ECC successfully addressed HTHP seal challenges in heavy oil recovery and geothermal well development. For broader acceptance in other industrial sectors, mechanical properties of this material still needs to be improved to overcome its current disadvantages including anisotropic physical property, low tensile strain, and limited elasticity. Development of this novel composite material not only help oil and gas industry to unlock new energy resource to satisfy steadily increasing global energy-demands, but also provide new insight to advanced material community in how to align academic research with industrial applications.

Commentary

With scarce of easy-to-reach traditional oil resources, oil and gas industry has to continuously make technology and operational innovation to unlock the so called “unconventional” reservoirs, including shale oil and gas, heavy oil, flammable ice, etc., to satisfy steadily increasing energy-demands from global economic growth which renewable or “clean” energy can hardly play significant role in near future. Among these unconventional resources which were used be regarded as infeasible to explore economically or technically, heavy oil is one of the most promising options and has already been broadly developed in countries like Canada, Kuwait, Venezuela, US, China, etc., because its global abundance (i.e., reports shows that current reserve of heavy oil is three times the total amount of conventional oil and gas combined). Unlike traditional oil, heavy oil is extremely viscous and cannot flow easily. In order to extract them from underground, large amount of hot steam is injected into heavy oil reservoirs (namely steam injection), heating the heavy oil up to reduce its viscosity. In this operation, downhole temperature can easily reach 600°F+, at which current downhole rubber seals fail due to material thermal decomposition. This poses great challenge to operational and environmental safety. Similar to heavy oil recovery, successful development of geothermal wells-one of the most popular renewable clean resources-also requires reliable seal of extremely high temperature rating (up to 1000°F+).

In other industries such as aerospace, metal-to-metal seal is standard solution to seal precisely machined parts in high temperature application, but hardly accepted by oil and gas industry. Downhole seal applications in oil industrial often requires reliable seals of relatively low grades of tolerance and rough surfaces, such as annular space between tubular and rough wellbore. In these scenarios, metal material lacks the necessary elasticity and malleability to seal these rough seal mates. Therefore, new materials, which exhibit high thermal stability as metal seals and high elasticity like rubbers, need to be developed to address this issue.

Over past decade, numerous amounts of efforts have been invested by both industrial and academic society to target this challenge, as demonstrated by large number of patents and research papers published recent years. Among them, industry mainly focused on complicated and well-tuned design to take fully advantage of available materials, e.g. wrapping rubber with metal shells, protecting rubber seal with more effective backup, etc.; while academic researchers mainly devoted on complete new materials or formulations that are super-elastic and thermally stable simultaneously [1], and these works include rubber enhancement with nanomaterial, complex lattice structure with metal material to simulate mechanical property of rubber, etc. It is true that exciting progress has been witnessed thanks to rapid development of nanotechnology and advanced fabrication technologies, however, to best of our knowledge, no elastic seal material has been reported to provide successfully seal over 600°F.

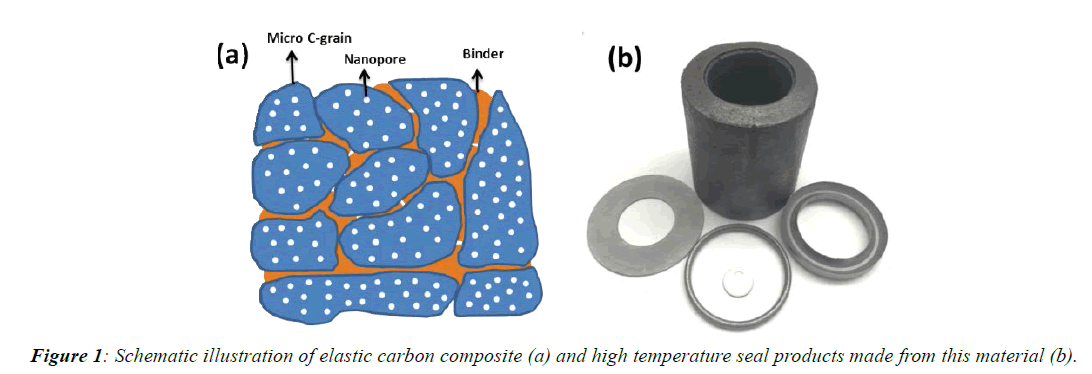

In the work “Advanced carbon composite material for heavy oil and geothermal energy recovery” and related publications [2,3], the authors obviously tried to address this high temperature seal challenge by taking the route of developing new advanced material. In their material design strategy, they selected expanded graphite (EG) as base material due to its excellent thermal/chemical resistance and seal capacity, and use advanced fabrication technology to add bi-continuous metal phase to bond these EG grains into an integrated composite. Due to their extremely thermal and chemical stability, carbon is probably one of the most inert materials in nature (i.e., suitable for HT application) and expanded graphite material have been broadly utilized and well accepted as excellent seal material in the form of gasket or foil seal. However, traditional expanded graphite seal product is typically weak, because they are fabricated by direct molding process and each graphite grain was connected only through weak physical lock. Therefore, these traditional seal can hardly keep their integrity under hydraulic pressure as encountered in downhole conditions. The innovation of authors’ work is finding an effective way to bond these loosely connected expanded graphite grains with metal binder phase in two ways: 1) the infiltrated metallic phase form strong carbide with graphite grains, thus bonding EG grains together; 2) after forming bi-continuous phase (Figure 1a), metallic binder also form a “network” or “backbone” to lock graphite grain in place, preventing disintegration of overall composite. This innovation is a great breakthrough in upgrading properties of traditional expanded graphite materials and broadly extending their applications into oil and gas industry. For example, because traditional expanded graphite is weak, they can only be used in form of thin foil (or its derivatives) to bear compressive load. The new carbon composite developed by authors behaves more like a plastic or soft metal, which means it can be fabricated and used in the form of all the typical seal geometries (as shown in Figure 1b), including O ring, V ring, packing element, etc. Because of this innovation, researchers and end-users no longer limit themselves to rubber based material to address HTHP seal issue in oil and gas industry, as any further improvement in temperature rating of rubber material not only requires extensive R&D efforts from engineering side but also highly rely on fundamental scientific breakthrough in complete material redesign in molecular or even atomic level-a task full of uncertainties and may not be realized in near future. In this novel composite material design, authors obviously focus more on problem-solving and end application by avoiding highly risky material research in rubber based materials. Based on their test data, they successfully address HTHP issue in the oil and gas by delivering a real and affordable seal product (i.e., elastic carbon composite packer) which passed 600°F and 3000 psi industrial standard test.

Besides mechanical strength enhancement, composite structure of this novel material also provides application engineer more design flexibility, e.g. hardness (or elastic modulus) of final composite can be continuously tuned ranging from extremely soft pure EG phase to metallic phases depending on ratio between EG and metal. Since carbon is both thermally and chemically inert, end users could also change the corrosion resistance of overall composite by selecting corresponding metallic binder material according to their specific applications. For example, if long lifetime and high reliability is the main concern, corrosive resistant alloys-including Copper, Nickel, Chromium, etc., could be used as binder; while for temporary seal scenario, selection of Magnesium or Aluminum as binder phase enables seal product with self-destructive capacity, a very useful functionality which eliminates needs of costly wellbore invention operation to retrieve or clean these downhole seals.

During operation in heavy oil recovery and geothermal wells, downhole temperature is not constant, but undergoes large range of cycles. This currently causes seal issues because Thermal Expansion Coefficient (TE) of rubber seal does not match with surrounding metals. In detail, because TE of rubber is typically one order higher than that of metals, rubber seal is overstressed or even damaged at high temperature, and overrelaxed when temperature is low, causing seal failure and thus incidents in both cases. As demonstrated by authors, this elastic carbon composite has nearly same TE as steels, and industry standard test shows that packing element made of this material can seal reliably between 600° and RT, completely addressing above issue. Last but not the least, incorporation of graphite phase gives carbon composite naturally self-lubricating property (even better than Polytetrafluoroethylene). It means this novel material can be used as dynamic seals or seals that have to provide reliable seal under unpleasant vibration or movement, another great advantage over rubber and metal seals.

Though the advantage and breakthrough of the elastic carbon composite mentioned above are tremendous, the composite itself still has some limitations. As shown in material design strategy (Figure 1a), incorporation of metallic binder phase does not change microstructure of expanded graphite grains, therefore elastic carbon composite also carries certain intrinsic limitations from EG. One of them would be anisotropic property. Similar to EG, elastic carbon composite has laminated microstructure, which means the mechanical property perpendicular to the lamination is totally different from that of parallel direction (typical stronger). Another limitation would be tensile strain. It is true that Elastic Carbon Composite has dramatically enhanced tensile strength compared with traditional weak EG material, however, it does not change the fact that this material can be only compressed (>50% compressive strain) but can only undergo <1% tensile strain before delamination. This material displays limited elasticity (typical <10% in un-confined condition and <50% when well-confined) compared with rubber material which typically shows elasticity over 100%. For this sake, previous data and knowledge gathered from rubber seal may not apply to ECC very well, and engineer may have to redesign seal geometry to make sure ECC works in compressive loading and lamination direction facing to sealing mate all the time. That explains authors utilized ECC powders instead of bulk piece in their packing element product, a cost-efficient but highly effective route to overcome this limitation [4]. From view of industrial acceptance, more data or “work experience” also need to be accumulated (e.g. life-time, fatigue, etc.) before it can replace rubber seal, with which people has used for over 100 years and already built a complete knowledge system from materials selection, seal design to end applications.

For conclusion, elastic carbon composite is innovative work to address HTHP seal challenges during development of heavy oil and geothermal wells in oil and gas industry, and has proven to be a highly effective and economically-affordable solution through successful product delivery. It has unique mechanical properties different from both rubber seal and metal-to-metal seal, potentially filling the seal market gap where rubber does not have enough temperature rating and metal lacks enough elasticity to work reliably. However, this material also suffers from disadvantages including anisotropic mechanical property, low tensile strain, and limited elasticity compared with rubber, which require special and sometimes more complex design to accommodate for practical applications. Both microstructure design and processing technology need to be further investigated in order to optimize its mechanical properties for broad acceptance in more industrial sectors.

References

- Endo M, Noguchi T, Ito M, et al. Extreme-performance rubber nanocomposites for probing and excavating deep oil resource using multi-walled carbon nanotubes. Adv Funct Mater. 2008;18: 3403-9.

- Xu Z, Zhao L, Ganguly P. Elastic carbon composite and its use as ultrahigh temperature packer element. SPE Middle East Oil & Gas Show and Conference. 2017.

- Xu Z, Zhao L, Prieto C. Ultra-high temperature rated elastic carbon composite packer for reliable downhole zone isolation. SPE Annual Technical Conference and Exhibition. 2017.

- Zhao L, Xu Z, Flexible graphite packer. US20160145965A1.