Mass Spectrometry Congress 2019

Journal of Chemical Technology and Applications | Volume 3

Page 18

May 20-21, 2019 | Rome, Italy

MASS SPECTROMETRY,

PROTEOMICS AND POLYMER CHEMISTRY

3

rd

International Conference on

OF EXCELLENCE

IN INTERNATIONAL

MEETINGS

alliedacademies.comYEARS

glass to ensure its suitability for the pH of the product; use COC/COP vial.

Present market demand is syringe barrel and/or plunger coatedwith silicone.

Non-uniform silicone coatings can affect protein stability. The proteins can

absorb into the walls of the container. While silicone can reduce absorp-

tion, excess silicone can form suspended oil-like droplets. Proteins can form

around those droplets and change their natural state. New lubricant coat-

ings, such as inert fluoropolymers, are being introduced to replace silicone.

As a very inert material, fluoropolymer provides smoothness for the syringe

plunger without the irregularities or the issues that have come with silicone.

Other new coating materials are being introduced with new types of pack-

aging related to self-injectors, especially injector pens, patches, transdermal

and wearable devices for self-infusion. Extractable and leachable are most

important for inhalers and catheters. For an extractables from a device com-

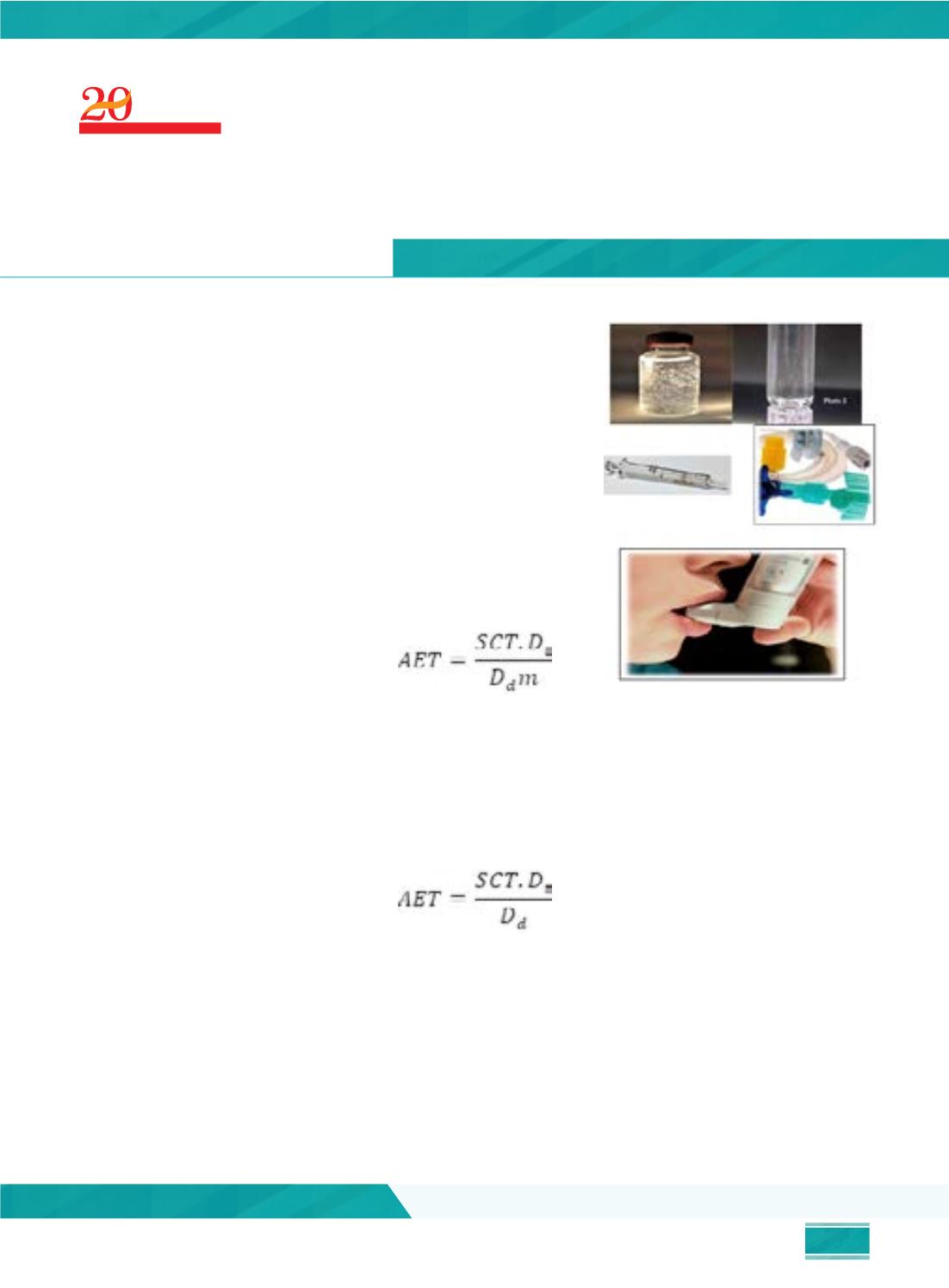

ponent the AET (μg/g) can be determined using Equation 1:

Where

Dd- Doses per day

Dt- Total Labelled doses

m- Mass of component

The AET (μg/device) for a drug delivery device (e.g. an MDI) can be determined from Equation 2:

Where

Dd- Doses per day

Dt- Total Labelled doses

Recent Publications

1.

AnupamChanda (2019) Packaging Challenge for Lyophilized Products. Acta Scientific Pharmaceutical Sciences

3.4: 87-91

2.

Anupam Chanda (2018) Packaging Challenge for Biosimilar products. J Bioanal Biomed10: 82