Research Article - Allied Journal of Medical Research (2018) Volume 2, Issue 1

Risk positions assessment in order to prevent musculoskeletal injuries in the tube manufacturing industry

Jhonathan Cuellar*, José Daniel Velázquez, Carolina Solís and Juan Manuel Hernández

Faculty of Chemical Sciences, Department of Industrial Engineering, Autonomous University of Nuevo León, Mexico

- *Corresponding Author:

- Jhonathan Cuellar

Industrial Engineering Autonomous University of Nuevo Leon, San Nicolas de los Garza, Nuevo Leon, Mexico

Tel: 01528123557617

E-mail: jhonathan.cuellarcls@uanl.edu.mx

Accepted date: December 12, 2018

Citation: Cuellar J, Velázquez JD, Solís C, et al.. Risk positions assessment in order to prevent musculoskeletal injuries in the tube manufacturing industry. Allied J Med Res. 2018;2(1):16:8.

DOI: 10.35841/medical-research.2.1.16-18

Visit for more related articles at Allied Journal of Medical ResearchAbstract

There are many activities performed in a repeated way and in a risk positions that cause fatigue and subsequently may origin cumulative trauma diseases and musculoskeletal disorders (MSD). Although the disorders may appear as a consequence of an intense effort, its development is a multifactorial process, but it usually occurs because the prolonged exposure in certain positions or movements. The disorders can be of different severity degree, since mild periodic symptoms to serious synchronous conditions. One of the main reasons why this kind of disorders occurs is due to the bad designed workplaces. In order to detect bad designed workplaces are important to evaluate consistently the jobs, especially the manual activities in the industry. Ergonomic assessments allow having a vision of the work situation in order to design safe, healthy and productive jobs. The purpose of this work was to evaluate the process expansion of the tube fabrication industry, and implement an evaluation system musculoskeletal complaint in the industry. The Quick Exposure Check (QEC) assessment is one of the observational tools, developed for health professional to detect risk exposure and it was used to evaluate the process expansion of the tube fabrication industry. The process was analyzed during two months, evaluating frequency, duration and load weight. The body segments evaluated were back, shoulder, arm, wrist and neck. The study was conducted among 30 workers. In this study we have evaluated the prevalence of Musculoskeletal Disorders (MSD) symptoms among workers of the process expansion of the tube fabrication and the prevalence reported by the respondents was very high; 80% of respondents reported having pain in the shoulders at the end of the day. Shoulder pain is one of the most common presenting complaints in the daily clinical practice and in the process expansion of the tube fabrication; this accumulative trauma disease can be provoked. Our purpose was to implement the evaluation system CCR in the process expansion of the tube fabrication industry.

Keywords

Quick exposure check, Cumulative trauma disease, Musculoskeletal disorders, Risk exposure level

Introduction

There are works related musculoskeletal disorders, which are developed consequently of work related activities, are a common health problem throughout the industrialized world and one of the major causes of disability. There are increased risks of musculoskeletal disorders, for some body parts; back, neck shoulders and upper extremities of the body. According to the Social Security Institute of Mexico, the MSD increased in the year 2015 by 47%. The MSD development MSD is multifactorial, but it is usually appear due to prolonged exposure in certain positions and movements that are apparently harmless, and are usually ignored until the symptom becomes chronical and a permanent damage.

The Quick Exposure Check (QEC) assessment is one of the observational tools developed for health professionals to evaluate the individual's exposure to accumulative trauma disorders risks [1]. It is a tool widely accepted by ergonomists and health professionals to determine the risk factor to which workers are exposed when performing a task. The QEC assessment is sensitive to change depending to the exposure, before and after an ergonomic intervention. It is a reliable and applicable tool in a wide range of jobs [2]. With a short training, the evaluation can usually be completed in 10 minutes for each task. This tool is used both for research and for making changes in the workplace. It is used in countries such as France, Norway, Iran, Saudi Arabia, Korea, Spain, South Africa, Brazil and Singapore [3-5].

Method

Study

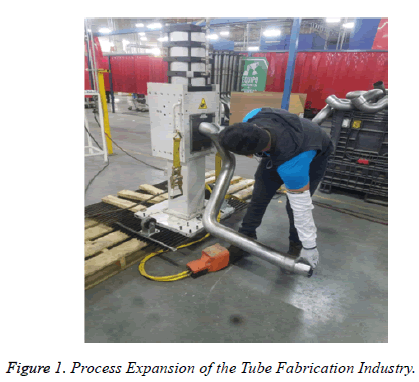

Fifty different kinds of positions were analyzed with the purpose to evaluate the frequency, duration and load weight in the manufacturing process tube. It was a non-probabilistic sample where the expansion process area was selected, according to these criteria. The operator holds and moves a 12 kg piece called “black swan”. The operation has to be made with the arms raised over the shoulder and with a lifting frequency of eleven times per minute. The operator manufactures 120 pieces on his 8 h workday. The study was conducted in two different work-shifts for two months (Figure 1).

The assessment was performed at the tube manufacturing industry located at the South area of Nuevo Leon state. All workers of the area were interviewed, the research´s objective was presented and they voluntarily accepted to participate in the assessment. Weight, age and height were recorded. The test-retest was used to calculate the measurement reliability coefficient (Pearson R=0.89). Additionally, the researchers involved in the assessment ensured confidentiality of collected data.

Assessment

The risk exposures were evaluated using the Quick Exposure Check assessment [1,6,7]. The QEC ergonomic evaluation sheet consists of 15 questions oriented to acknowledge duration, frequency and load weight. The assessment is structured in four blocks, corresponding to body segments (back, shoulder/arm, hand/wrist, neck) and four sections which correspond to additional factors (driving, vibration, work rate and stress). The scores are selected from the answers obtained. Once identified, the crossing point of the combination is obtained. The rest of the scores are identified in the evaluation. The total segment score is obtained by adding each column partial scores. Finally, the body segment total score is added. The same procedure was repeated for each body segment, and the QEC assessment provides exposure scores for each body area (Table 1) [1].

| Height (C) Weight (H) | |||

| C1 | C2 | C3 | |

| HI | 2 | 4 | 6 |

| H2 | 4 | 6 | 8 |

| H3 | 6 | 8 | 10 |

| H4 | 8 | 10 | 12 |

| Height (C) Duration (J) | |||

| C1 | C2 | C3 | |

| J1 | 2 | 4 | 6 |

| J2 | 4 | 6 | 8 |

| J3 | 6 | 8 | 10 |

| Duration (J) Weight (H) | |||

| J1 | J2 | J3 | |

| HI | 2 | 4 | 6 |

| H2 | 4 | 6 | 8 |

| H3 | 6 | 8 | 10 |

| H4 | 8 | 10 | 12 |

| Frequency (D) Weight (H) | |||

| D1 | D2 | D3 | |

| HI | 2 | 4 | 6 |

| H2 | 4 | 6 | 8 |

| H3 | 6 | 8 | 10 |

| H4 | 8 | 10 | 12 |

| Frequency (D) Duration (J) | |||

| D1 | D2 | D3 | |

| J1 | 2 | 4 | 6 |

| J2 | 4 | 6 | 8 |

| J3 | 6 | 8 | 10 |

Table 1. QEC Ergonomic Evaluation Sheet.

Exposure Scores

In order to understand the results, risk factors are: load weight, duration, frequency, posture, task height and visual demand, are considered for each body segment total score. Once the evaluation is completed, body segment crossing score are added with the purpose of obtain risk exposure level (Table 2).

| Score | Low | Moderate | High | Very Heigh |

|---|---|---|---|---|

| Back | 10-20 | 22-30 | 32-40 | ≥30 |

| Shoulder/Arm | 10-20 | 22-30 | 32-40 | ≥42 |

| Hand/Wrist | 10-20 | 22-30 | 32-40 | ≥42 |

| Neck | 4-6 | 8-10 | 12-14 | ≥42 |

Table 2. Exposure Level.

Exposure Level According with Body Segments Scores

The QEC ergonomic assessment is a powerful tool that should be used in the industry in order to evaluate people´s health and safety risks [3,8]. For this reason, it was decided to use the ergonomic QEC tool because is widely accepted by ergonomists and health professionals in order to detect risk factors. For the assessment, an arbitrarily selection of people participated voluntarily after receiving information about the objective.

Results

The most prevalent musculoskeletal complaint was shoulder pain (80%), back pain (65%) and neck pain (58%). The age of the subject is an important factor for MSD. The age group between 35-40 is more exposed to musculoskeletal disorders, because have 58% of occurrence of MSD. According to QEC scores, exposure levels of back, shoulder and neck were found to be Very High.

Conclusion

We propose the implementation of evaluation system CCR (Complaint, Check, and Redesign). The first step of the system is to know the “complaints” of the workers. According with the Federal Labor Law of México every company with more than 100 workers must to have a medical department. This department must collect work-related complaints in order to identify risk exposure that may origin a MSD. In this Study we were supported by the medical department, who has a record of worker´s complaint, but not in a systematic way. The record was modified placing the cause and the possible injury.

Some injuries with high incidence in the upper body´s part are; Rotator cuff tendinitis and supra-spiny syndrome. The rotator cuff usually occurs in people, whose age is over forty years, but it can also occur at a younger age if excessive and repetitive activities are performed, which can accelerate the presence of this trauma [9,10]. Shoulder´s articulation has characteristic that makes it especially susceptible to injury, due to low blood flow to the tendons, and if it is damaged does not regenerate easily. In order to detect symptoms of this trauma, periodically medical checkup should be realized. The Jobe, Yergason, Patter and Gerger tests are a proposal evaluation tool in order to detect supraspinatus muscle rupture. These tests must be made in the medical department once a month.

The second step is to “Check” the high incidence area, using the QEC assessment tool once a year. We recommend QEC assessment because is simple and easy to use if it is compared with other assessments. The third step is to “Redesign” the workplace based in ergonomic principles supported mainly in anthropometric measures. Due to the chances that occur in weight and height anthropometric measures need to be review once a year. MSD is a significant occupational health problem in the manufacturing process tube. This study demonstrated that shoulder, back and neck are more at risk in terms of MSD. The workers should receive training on evaluation system CCR in order modify workplaces and eliminate the risks related to work related musculoskeletal disorders.

References

- Ramasamy S, Adalarasu K, Patel TN. Evaluation of driving-related musculoskeletal disorders in motorbike riders using Quick Exposure Check (QEC). 2017;28:1962-68.

- Bozkurt S, Demirsoy N, Günendi Z. Risk factors associated with work-related musculoskeletal disorders in dentistry. 2016;39:192-6.

- Ozcan E, Kesiktas N, Alptekin K, Ozcan EE. The reliability of Turkish translation of quick exposure check (QEC) for risk assessment of work related musculoskeletal disorders. J Back Musculoskel Rehab. 2008;21:51-6.

- López Á, Lorenzo G. Arthroscopic Treatment of Calcific Tendonitis of the Shoulder. Rev Cubana Ortop Traumatol. 2017;31:118-30.

- Antochevis-de-Oliveira M, Toscani-Greco PB, Cassol-Prestes F, et al. Musculoskeletal disorders/pain in undergraduate nursing students in a community university in southern Brazil 2017;47:160-74.

- Gomez AB. Evaluación del estado nutricional del adulto mediante la antropometria. Revista Cubana Aliment Nutr. 2002;16:146-52.

- Verde de Almeida MC, Cezar-Vaz MR, de Souza Soares JF. The prevalence of muscoskeletal diseases among casual dock workers. Rev Latino-Am Enfermagem. 2012;20:243-50.

- Setiawati R, Rahardjo P, Hartono B. Influence of weightlifting on the emergence of partial and full thickness rotator cuff tear detected by ultrasound imaging. Folia Medica Indonesia. 2014;50:52-7.

- Garbin I, Soares B, Arcieri M, et al. Musculoskeletal disorders and perception of working conditions: a survey of Brazilian dentists in Sao Paulo. Int J Occupat Med Env Health. 2017;30:367-77.

- Nelson NA, Park RM, Silverstein MA, et al. Cumulative Trauma Disorders of the nad and wrist in the Auto Industry. American Journal of Public Health 1992;82:1550-2.